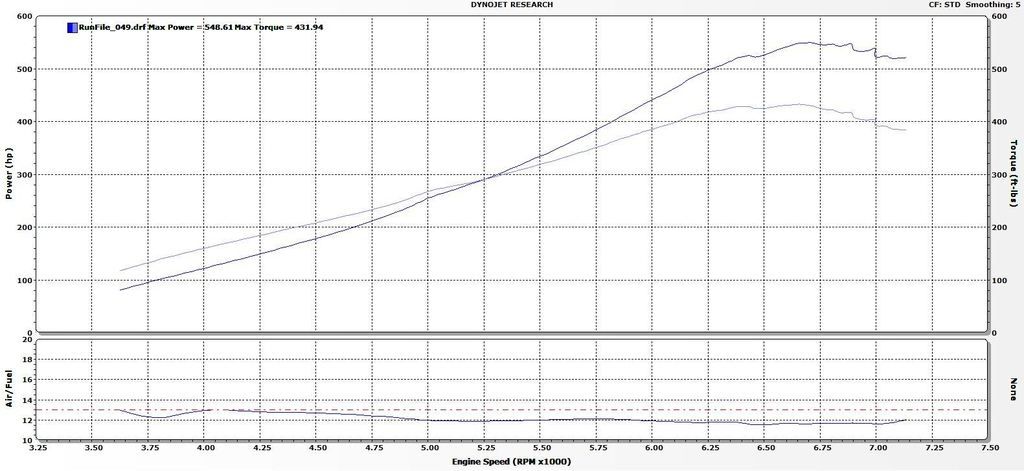

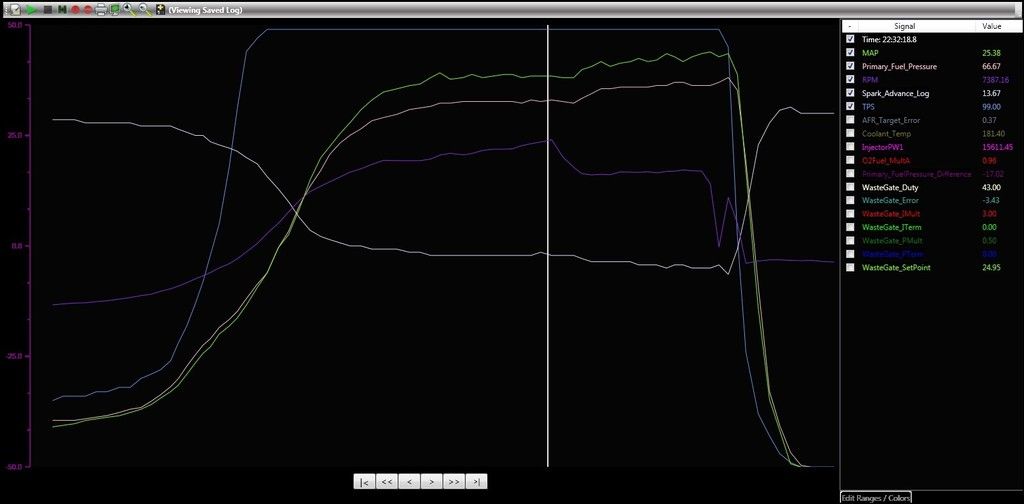

Nosechunks;2030598 said:Thanks! Yea im thinking of going in the beginning of next year. Maybe around April. I gotta finish the tune. Its only tuned on 20psi and i want to dial in the timing at 25 psi. Might go a little bit higher. Id love to get a 9.999999999 time slip. :biglaugh:

Thanks! Yea the whole hood is CF. I was originally going to paint the whole thing. When i was making the two repairs and sanding it for paint, i wet it down with the hose. It looked so sick wet i decided i had to leave a portion of it CF. Both repairs i had to make were on the side portions, and i always thought just having the middle CF looked good. So thats how it ended up. I wish i knew the brand of the hood. I got it used and have no idea what brand it is.

Ah, that's what I thought, that the center part was the only exposed carbon fiber part, but I wasn't sure if the pictures were deceiving me or not. The car looks great like that, it definitely adds a different touch too, I don't think I've ever seen another car done like that, let alone a MK3.