^^^ And that will give you 60-80 psi of pressure...make sure the rest of the oil system can handle it. For stock or light/medium mods, 5mm is plenty

Ways to cure 7M oiling issues

- Thread starter williamb82

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dub: That and Losing the Rod holes and Stock cooler circuit and running large bore -10 fittings in a full flow cooler give me my 10 psi per 1000rpm and 40+psi Hot Idle.

IJ: What do you have for a cold idle? And what weight oil do you run?

I finally changed to a multi weight 10W-40 after the break in. I still need to do a leak-down but by all visual reports it seems that I have no smoke at all during accell or decell. Yeaaa!!!

I finally changed to a multi weight 10W-40 after the break in. I still need to do a leak-down but by all visual reports it seems that I have no smoke at all during accell or decell. Yeaaa!!!

While I had all the parts out I made a test fixture to test the "opening point" of the oil squirter "Check Valves" as Toyota calls them. These items are a bolt with a ball bearing held pressurized with a coil spring in the closed position the oil exits similar to the way oil would exit a banjo bolt. If you have been following this thread chances are you know all about them. Heres a photo of a set of new ones.

Most of the ones in good condition seemed to open above 45psi and all seemed to flow at least a small amount as low as 10 psi. Obviously I was testing with air pressure, so it is highly possible they flow nothing until their designed pressure release of above 45psi with oil behind them. Watch the videos I find it very interesting to see how they actually operate when tested.

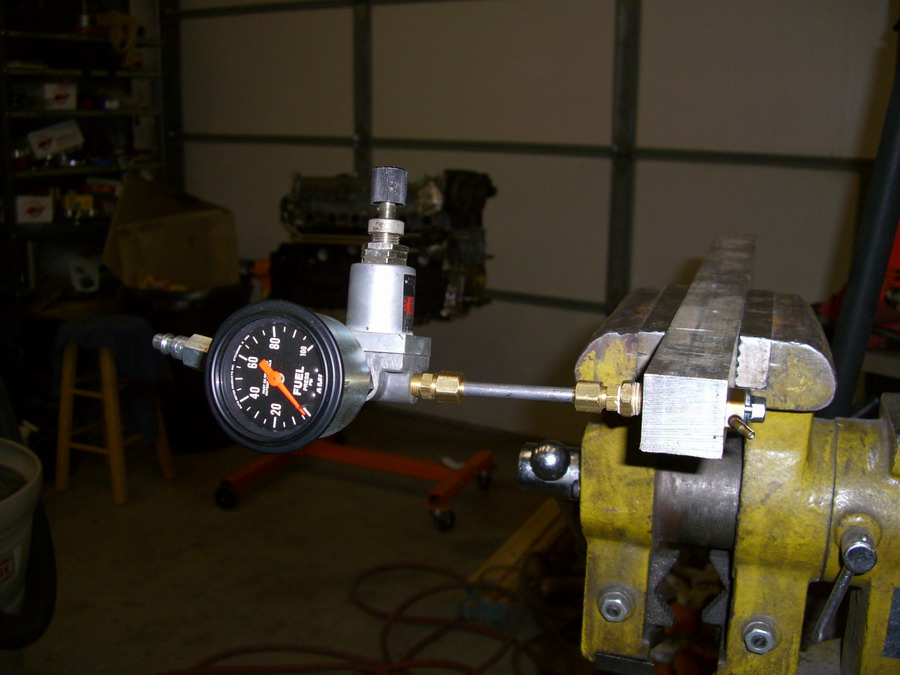

Heres a photo of my test rig, very simple actually, but seemed to work great.

As promised, here are a few videos of oil squirters used and new. You might be surprised at how they perform.

First video of used Oil Squirter

Video of New Oil Squirter

Video of Good working 130,000+ mile Oil Squirter

Video of 200,000+ mile Oil Squirter Nozzles/Check Valves

Most of the ones in good condition seemed to open above 45psi and all seemed to flow at least a small amount as low as 10 psi. Obviously I was testing with air pressure, so it is highly possible they flow nothing until their designed pressure release of above 45psi with oil behind them. Watch the videos I find it very interesting to see how they actually operate when tested.

Heres a photo of my test rig, very simple actually, but seemed to work great.

As promised, here are a few videos of oil squirters used and new. You might be surprised at how they perform.

First video of used Oil Squirter

Video of New Oil Squirter

Video of Good working 130,000+ mile Oil Squirter

Video of 200,000+ mile Oil Squirter Nozzles/Check Valves

Last edited:

Nice tests Andy! I'm glad I'm abusing the download rates from my works T3 modem, finished each file in under 4 mins. That would take all night for just one on my home computer!

Your last link does not work for me . It's too bad you can't have the high pressure flow of the broken in oil squirter and the low pressure opening point of the new one all in one package...

. It's too bad you can't have the high pressure flow of the broken in oil squirter and the low pressure opening point of the new one all in one package...

Your last link does not work for me

Last edited:

wow lots of useful info here guys, keep it up..

i was talkin to jon at mdc and he said he just put a #5 SBC oil pump relief spring in the pump and that gave him 40 some psi at like 3000rpm... anyone know anything else of this?? and what other kinds of mods aside from an oil cooler and relocation kit would i need to be safe for such pressure??

sorry if im redundant at all, i didnt have time to read through every single post

i was talkin to jon at mdc and he said he just put a #5 SBC oil pump relief spring in the pump and that gave him 40 some psi at like 3000rpm... anyone know anything else of this?? and what other kinds of mods aside from an oil cooler and relocation kit would i need to be safe for such pressure??

sorry if im redundant at all, i didnt have time to read through every single post

Bummer I will fix it tonight.starscream5000 said:Your last link does not work for me. It's too bad you can't have the high pressure flow of the broken in oil squirter and the low pressure opening point of the new one all in one package...

That one is the most shocking. It shows the valve flowing freely from as low as 10 psi. It never exhibits a definate opening point, if you had 6 oil squirters like this in your motor your bearings might seriously suffer. That one is the very reason I replaced them all.

+200K Vid link fixed, here it is again so you dont have to go back.

Video pressure test of +200,000 mile oil squirter

Video pressure test of +200,000 mile oil squirter

Interesting indeed. Im curious to see what my oil pressure will be like with your mod since I dont have squirters

It shouldn't make any difference at all...... :nono:mk3forme said:Interesting indeed. Im curious to see what my oil pressure will be like with your mod since I dont have squirters

Actually I meant what my oil pressure w/o squirters vs with and with the 5mm shim in the pump. I realize this mod is more for flow and not pressure increase.IJ. said:It shouldn't make any difference at all...... :nono:

Adjuster

Supramania Contributor

I think you lose more pressure via the stock rod bearing squirter holes than you do via the block mounted, and ball/spring regulated oil squirters.

Larger holes in the rod bearings than the squirters too. (And the LAST place you want to lose oil pressure, at the rod bearings.)

I think this oil hole design is a good part of why many 7M engines have spun rod bearings in the past. (That and running too low on oil, but combine them, and you get a easy path to rod knock via oil loss and bearing wear on the rods.)

Just my .02, but to get rid of the stock oil holes was a major reason I changed to the Pauter rods. (That and the stroker motor.)

Larger holes in the rod bearings than the squirters too. (And the LAST place you want to lose oil pressure, at the rod bearings.)

I think this oil hole design is a good part of why many 7M engines have spun rod bearings in the past. (That and running too low on oil, but combine them, and you get a easy path to rod knock via oil loss and bearing wear on the rods.)

Just my .02, but to get rid of the stock oil holes was a major reason I changed to the Pauter rods. (That and the stroker motor.)

Greg: This is why I shoot for 40+ psi at idle I don't like the idea of not much lubrication without the stock Rod holes

The Group A pan has a not too bad windage tray in it so splash is minimal.

The Group A pan has a not too bad windage tray in it so splash is minimal.

arz said:+200K Vid link fixed, here it is again so you dont have to go back.

Video pressure test of +200,000 mile oil squirter

Very interesting indeed. I would rather have six of those oil squirters than six new ones as this one seems to flow (based on the sound) starting around 10 psi and all the way to 80. The others seemed like they stayed closed until 40ish, but some small flow in the lower range. What's your take on this?

I would rather have six of those oil squirters than six new ones as this one seems to flow (based on the sound) starting around 10 psi and all the way to 80

Im not sure why you say that? Every ounce of oil that goes out the squirters does not go to the bearings. You only want the squirters to flow when the rpm's/pressure (and theoretically) the load/heat are up. The main objective of the oil squirters is to cool the bottom of the piston. Some theorize that the aerated oil might cause more foaming and possible resistance to windage than its worth in the piston cooling department.

Everybody, please add to this answer if I missed something.

Last edited:

Like I said, based on the sound from the video the last squirter you tested seemed to flow more evenly than the others, but the windage is a factor that needs to be taken into consideration too... And I wasn't talking about lubing the bearings, I was talking about the oil hitting the bottom of the piston to keep it cooler than a squirter that only wants to do it after the pressure gets up to about 40ish psi...

The squirters are basically a "controlled leak"...they will rob psi/flow from the bearings if they open up at too low a psi. You really don't need them until higher rpm to help keep the pistons cool.