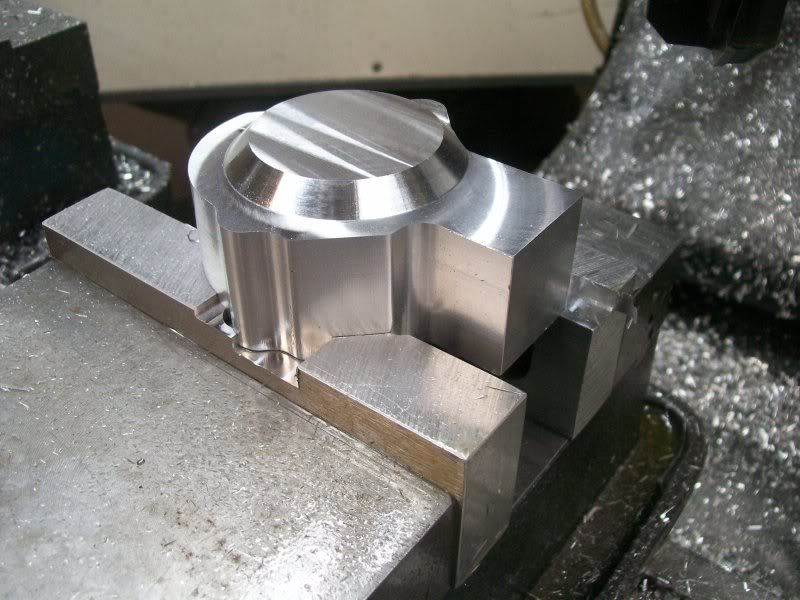

UPDATE ON PAGE 4!! FINALLY MADE THE PROTOTYPE!

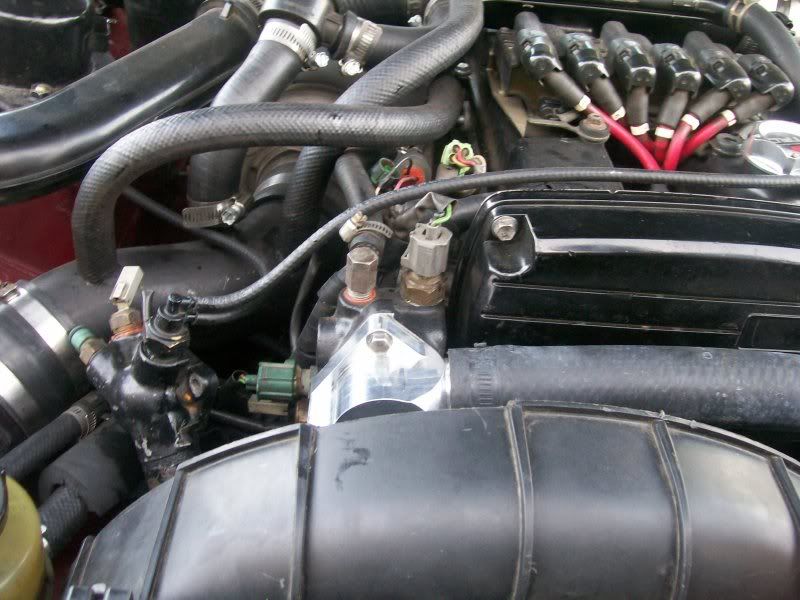

TEST FITTED ON PAGE 5!

THE HOSE FITTING WILL BE BARBED! DON'T WORRY!

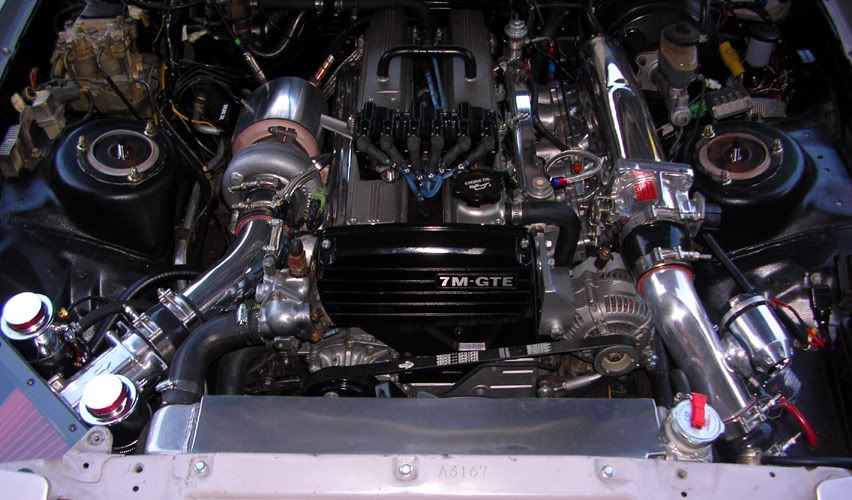

I'm working on making one of these for myself, and I wanted to see if anyone else is interested in them also. I also Want to get some suggestions from everyone.

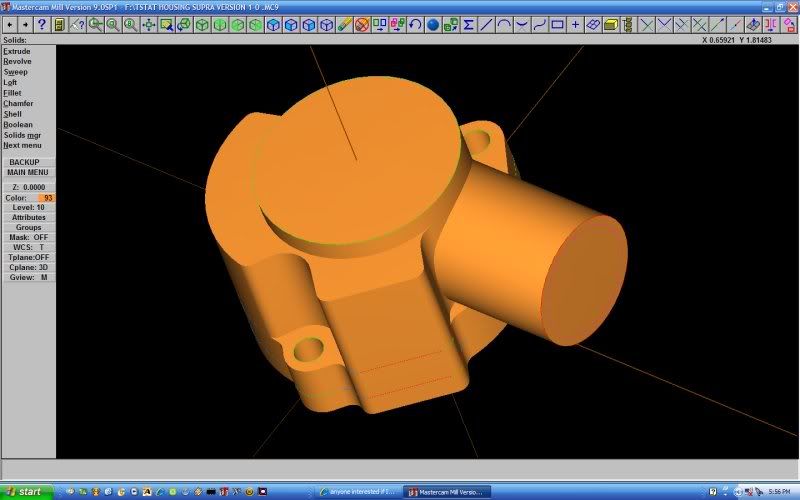

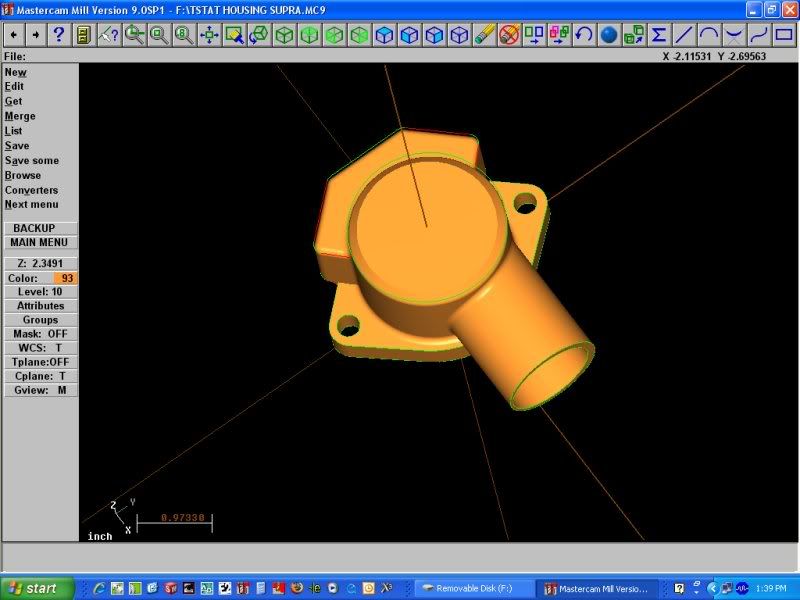

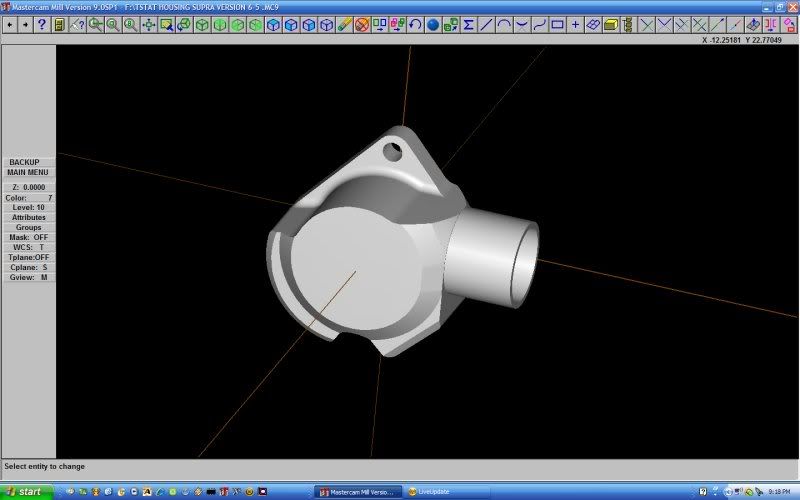

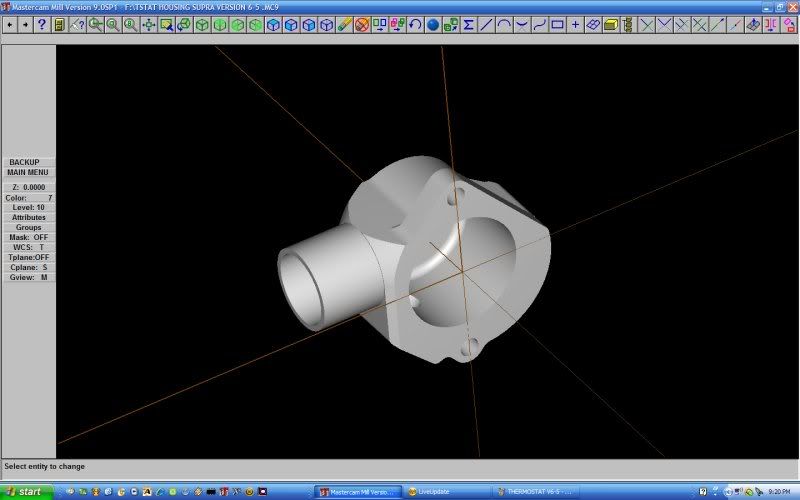

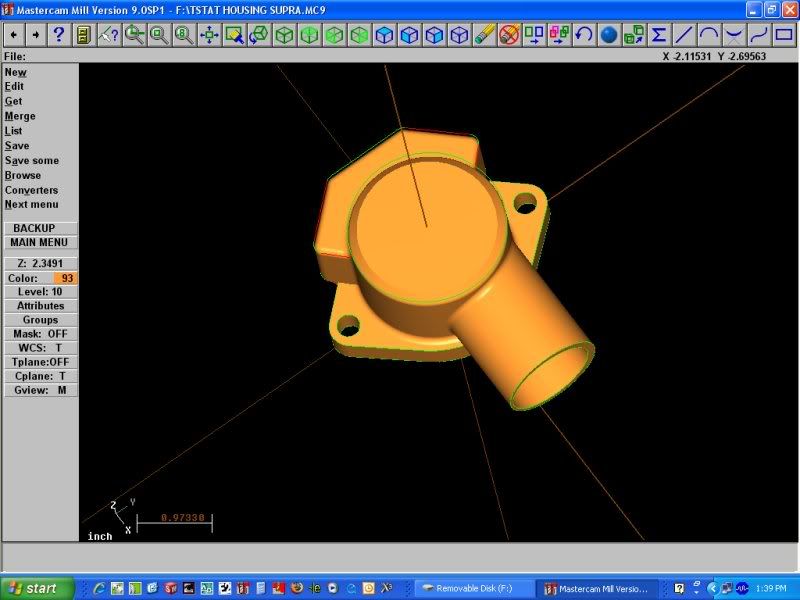

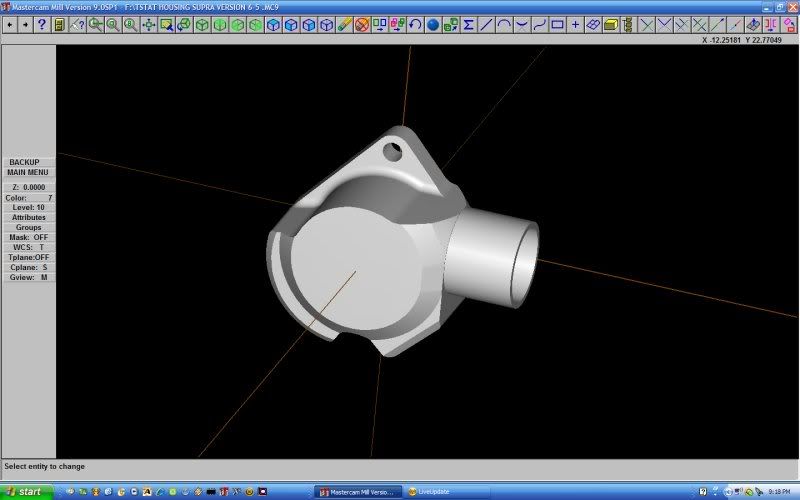

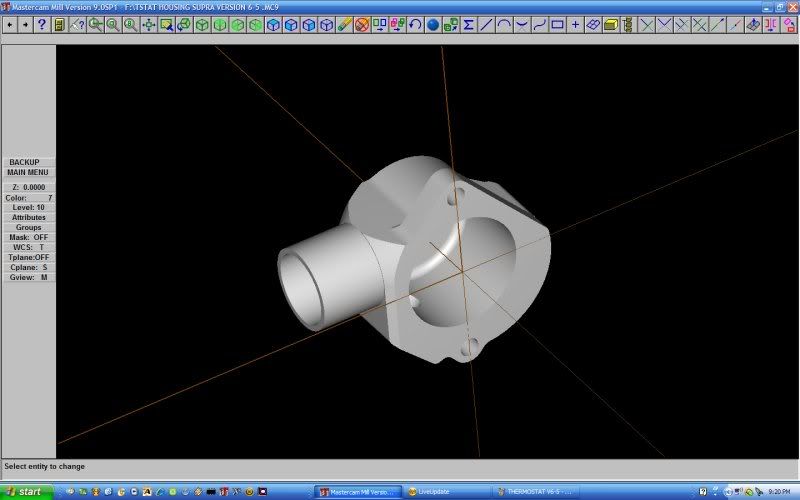

Here's the first draft of the solid model. It's kind of rough...

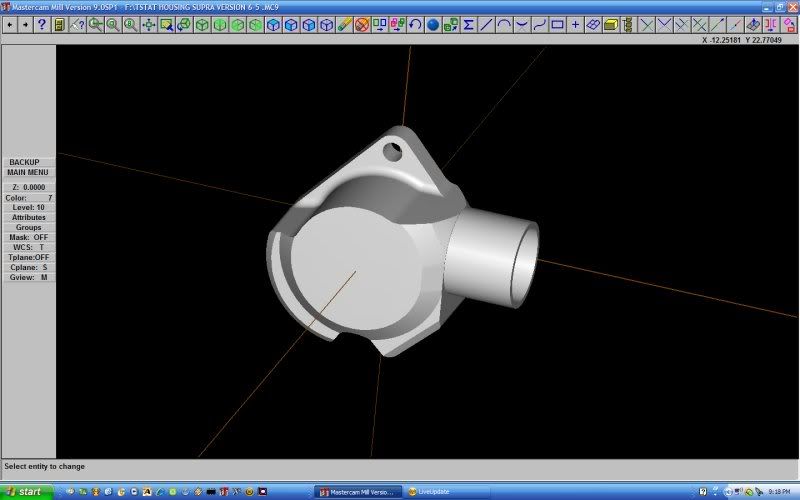

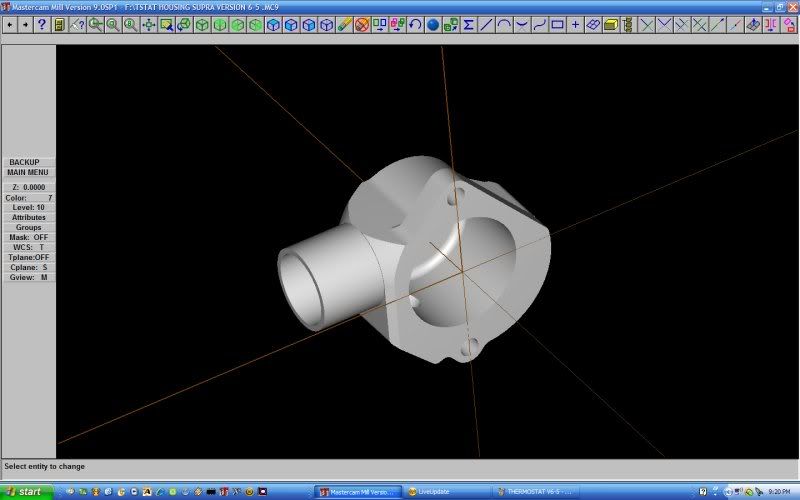

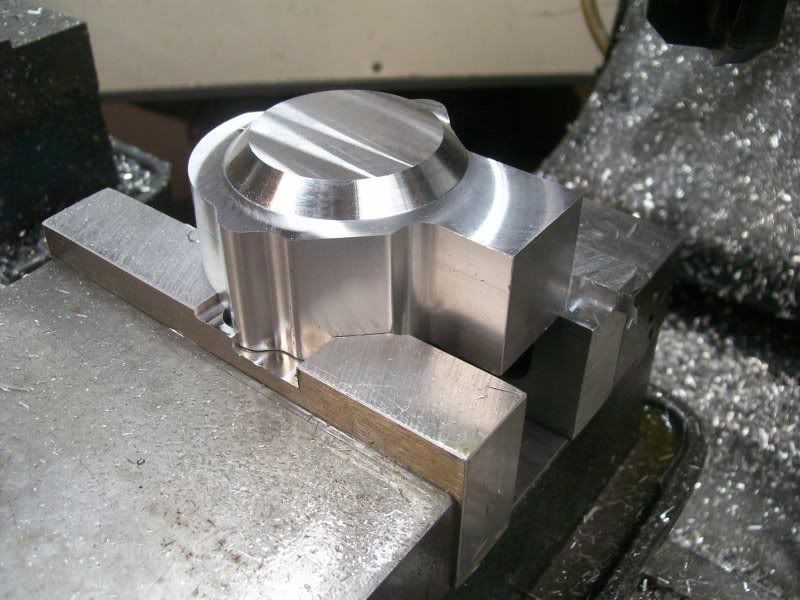

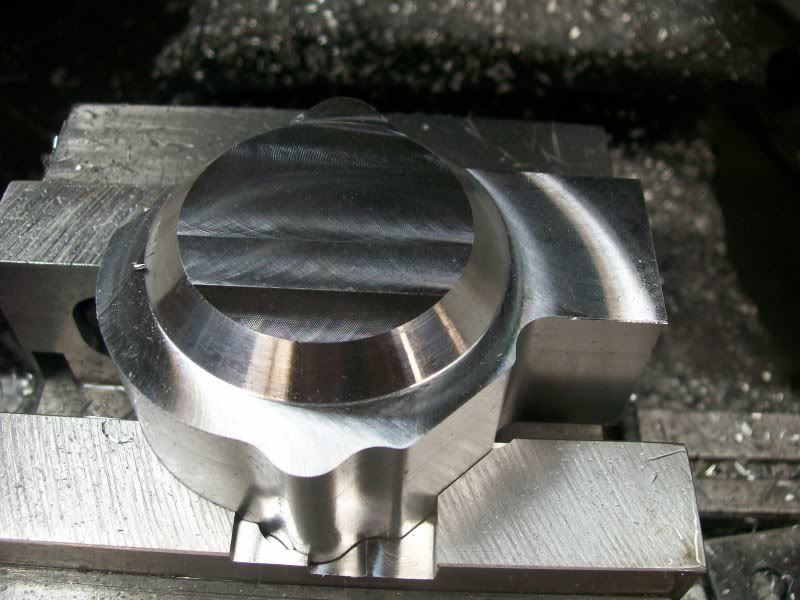

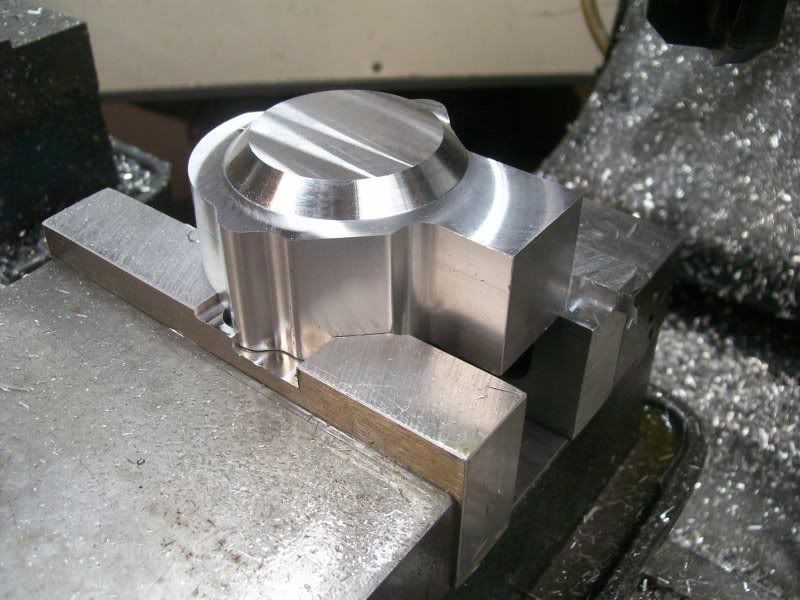

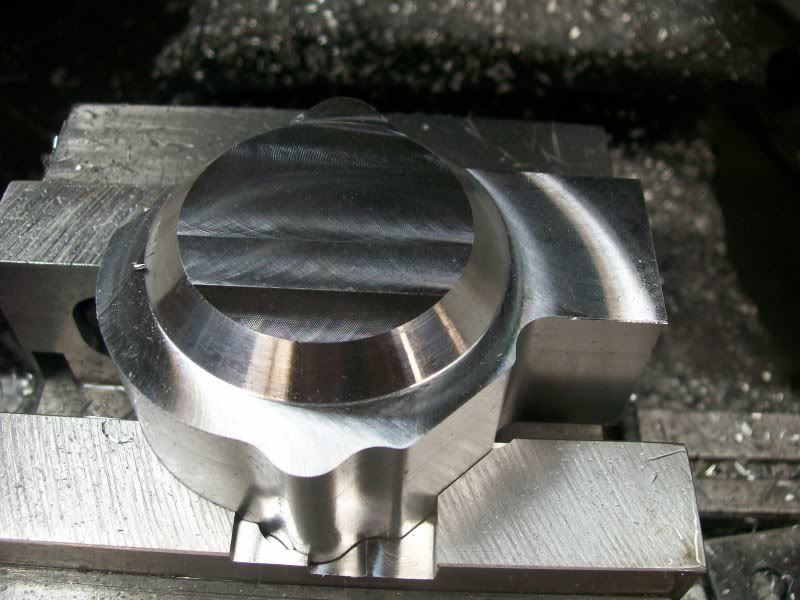

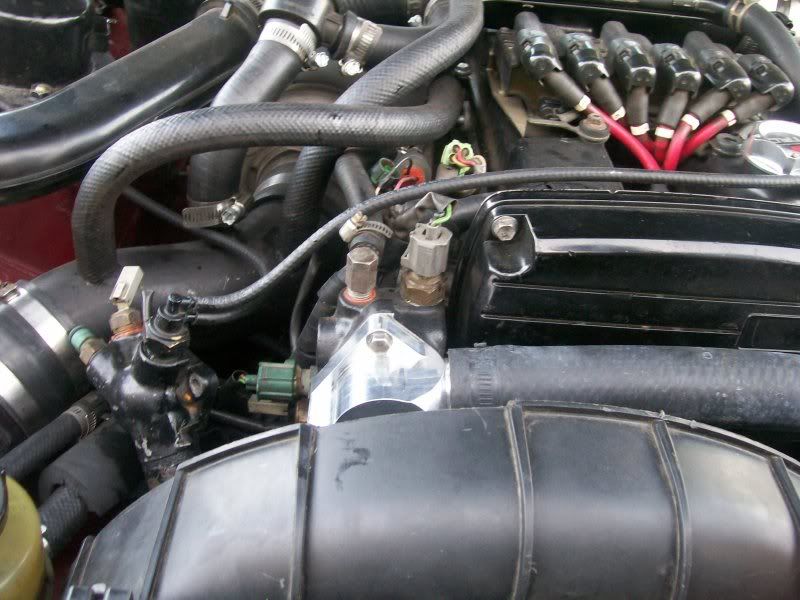

update on post #34

TEST FITTED ON PAGE 5!

THE HOSE FITTING WILL BE BARBED! DON'T WORRY!

I'm working on making one of these for myself, and I wanted to see if anyone else is interested in them also. I also Want to get some suggestions from everyone.

Here's the first draft of the solid model. It's kind of rough...

update on post #34

Last edited: