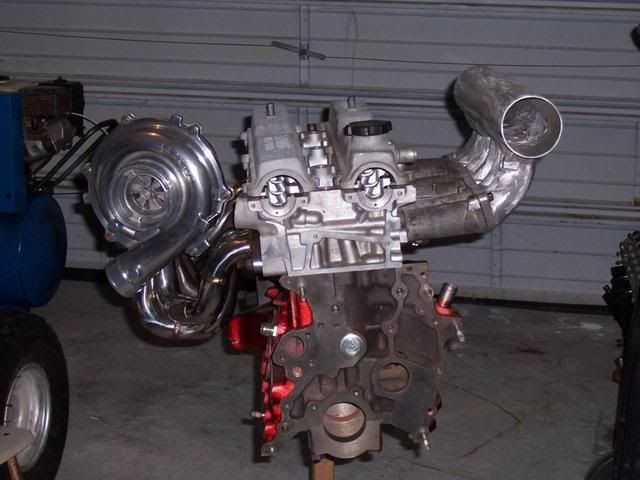

as most of you know ive been planning a front facing intake manifold for a long time. well this weekend had unexpected free time so me and my friend brian got a good start. i forgot my camera so these are the crappy cell pics i took. he is taking it to work to weld tis week then ill test fit it on the car and mark where im cutting the tube and make the end cap and tb flang. no iscv or cold start injector for me. dont need them. i have a polished 75mm ford tb ill be using and this pipe i recall was ~3.5in diameter. ive had it for awhile and planned to use it as at 16-18in long ill have the volume i wanted. its a long runner manifold obviously. gonna test fit it on the car to see if it clears the strut brace or if itll need a lil "massaging" lol. i did a rough measurment and it should just barely clear. lol. and dont worry how ugly it is. the plan is to polish it to match the tb.

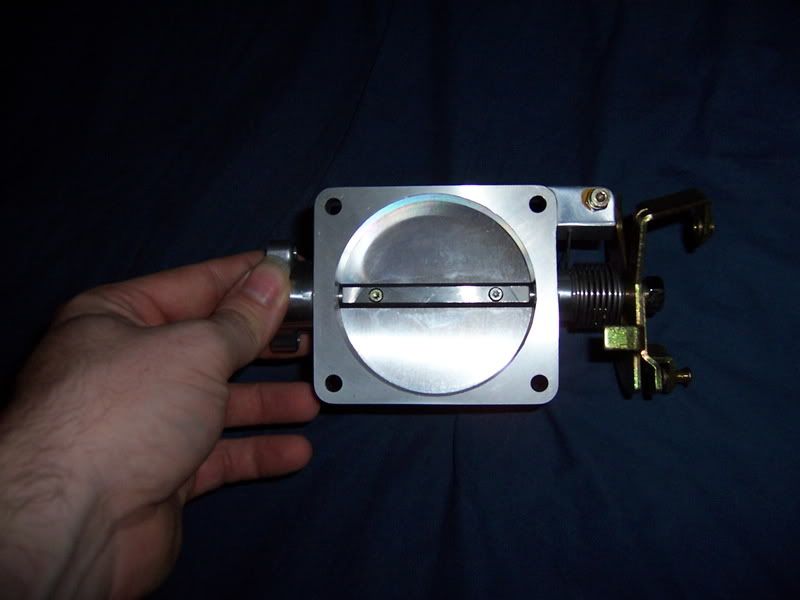

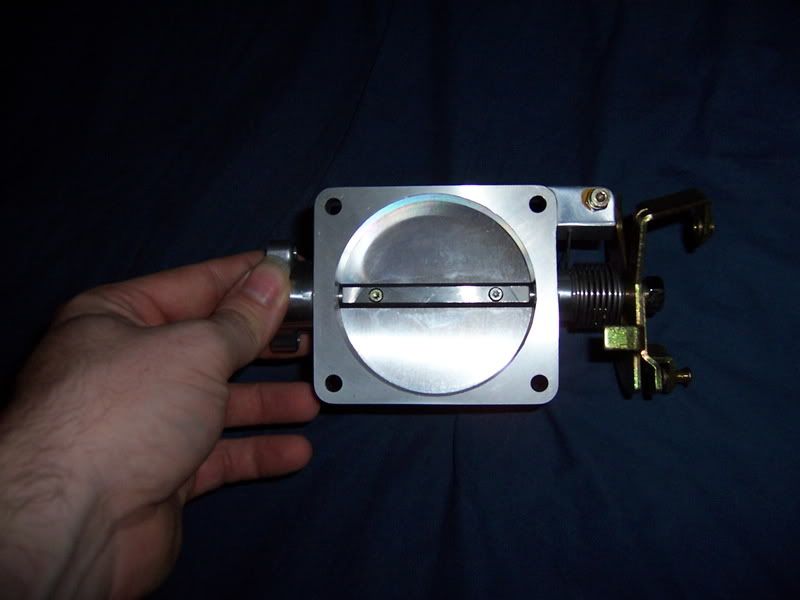

and the tb pics.

and the tb pics.