Has anyone thought of making FFIM molds and either doing cast aluminum or epoxy casting?

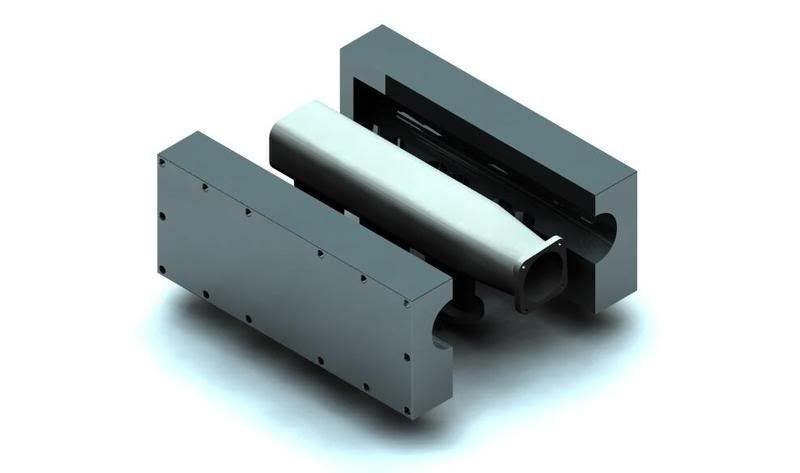

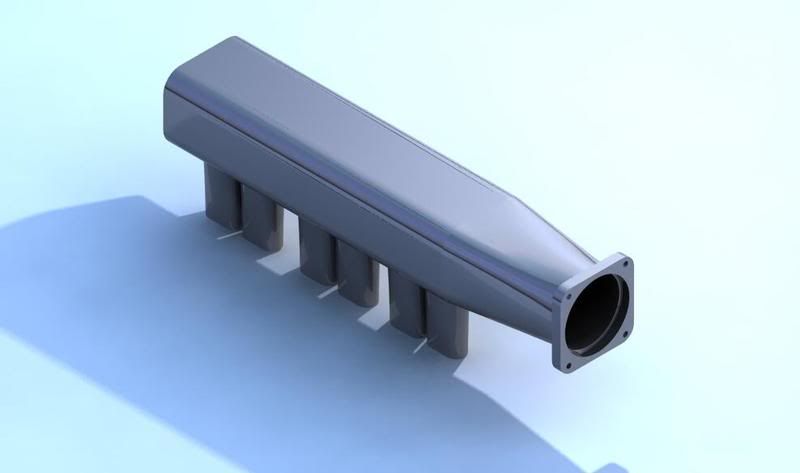

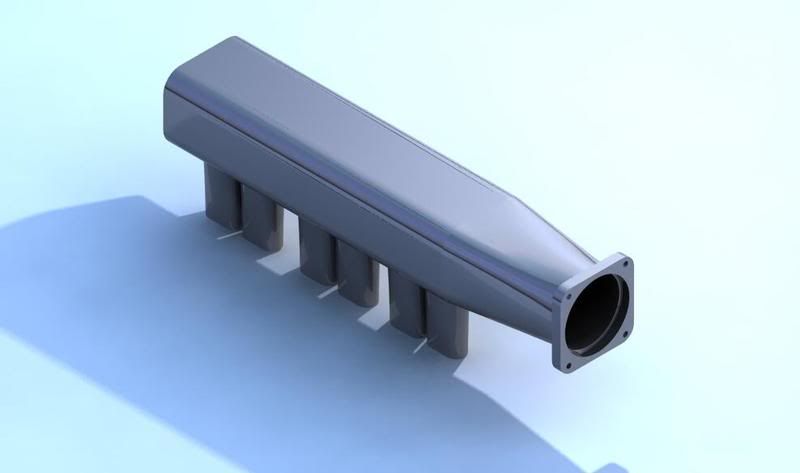

The latest 2J intake manifold got me interested, so I started making some models.

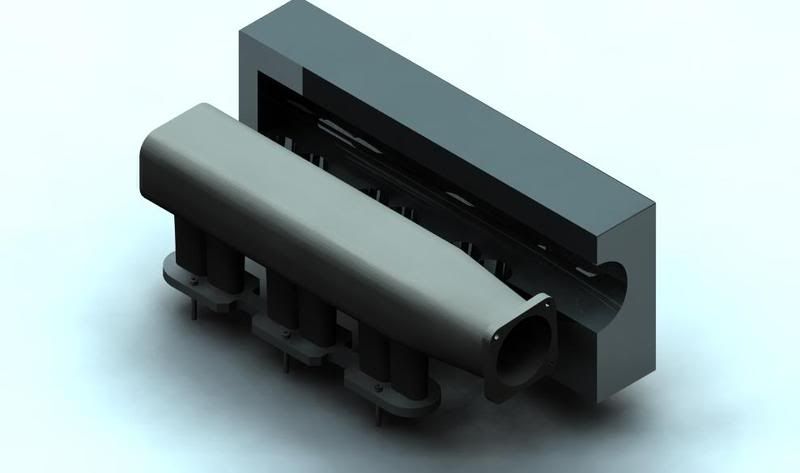

The mold would be expensive, depending on what material it's made out of... so that's when I thought maybe to do them in a 2-part epoxy or urethane.

Anyway, just some thoughts...

Has anyone ever done molds with shells?

I've only ever done solid molds where a core is encapsulated in epoxy or urethane.

The latest 2J intake manifold got me interested, so I started making some models.

The mold would be expensive, depending on what material it's made out of... so that's when I thought maybe to do them in a 2-part epoxy or urethane.

Anyway, just some thoughts...

Has anyone ever done molds with shells?

I've only ever done solid molds where a core is encapsulated in epoxy or urethane.