ok, i was given incorrect info then. i havent taken that plug off to clean it yet. i was told by a guy i know that all the rx7's had thermostats built in, i have seen it before about the t2 models do so now im not so sure. either way ill still use this cooler. its in good shape and isnt rotted, though ill have it flushed and checked at a rad shop before use. only cost $10 and it is huge. lol.

Ways to cure 7M oiling issues

- Thread starter williamb82

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yep I have run that same cooler on other turbo vehicles for over 10 years and was told that was a thermostat bypass too. I will be taking mine apart shortly to confirm also.

Never the less it has always served me well.

Never the less it has always served me well.

Adjuster

Supramania Contributor

RX7 turboII engines used a thermostat equipped oil cooler. I have mine tig welded at the mounting brackets to the end tanks on my FMIC. (Very little surface area actually touches between the two, and it's lined up perfectly so the upper grille air flow goes over the oil cooler and the lower grilled air flow goes over the FMIC. One of these days, I'm adding a air flow diverter design that will allow even better air flow through these, and keep the air flow seperated better.

The thermostat works. I took mine apart, and re-tapped the stock sized fittings which were AN8 to AN10. (The stock ID in and out on the cooler.)

Same with the oil pump. I've modifed and ported my oil pump to accept AN10 fittings. (You can get BSP 18mm 90 fittings to AN10, but the ID of the fitting is not giving you full flow.) Same goes for the stock fitting on the filter side of the block. You have to drill and tap the block for a larger 20mm BSP to AN10 fitting, to get full ID maintained from the pump to the exit point on the block.

To keep the AN10 sized theme, we tapped and plugged the small drilled out passage that normally feeds the stock filter boss on the engine block. The stock main galley thread is 20mm, so a BSP to AN10 fitting works great there, no mods required.

I use a 1/2" NPT compression thread on the outlet where the NA cooler bypass would bolt up to the block. (The GTE has a simple block off plate there stock.) If I did it again, I'd go 20 BSP to AN10 as the straight threads of the bsp fitting don't stress the block like the 1/2" NPT ones do.

I broke a block using the 1/2NPT thread fitting on the rail port. (SUCKED FOR SURE< had to tear down the entire motor, and re-machine the block for a BSP20 to AN10.. Note how low mine is compared to stock which is at the oil pan rail height.)

Shimmed the pump with a 10mm nut, and two washers. Also ported the pump to smooth flow out of the pump. No sharp edges on the corners between the pump gears and the exit point into the 90 BSP fitting.

I don't know why there should be a problem using stainless line inside the pan. It's pretty rugged stuff, and should hold up to the heat and oil just fine.

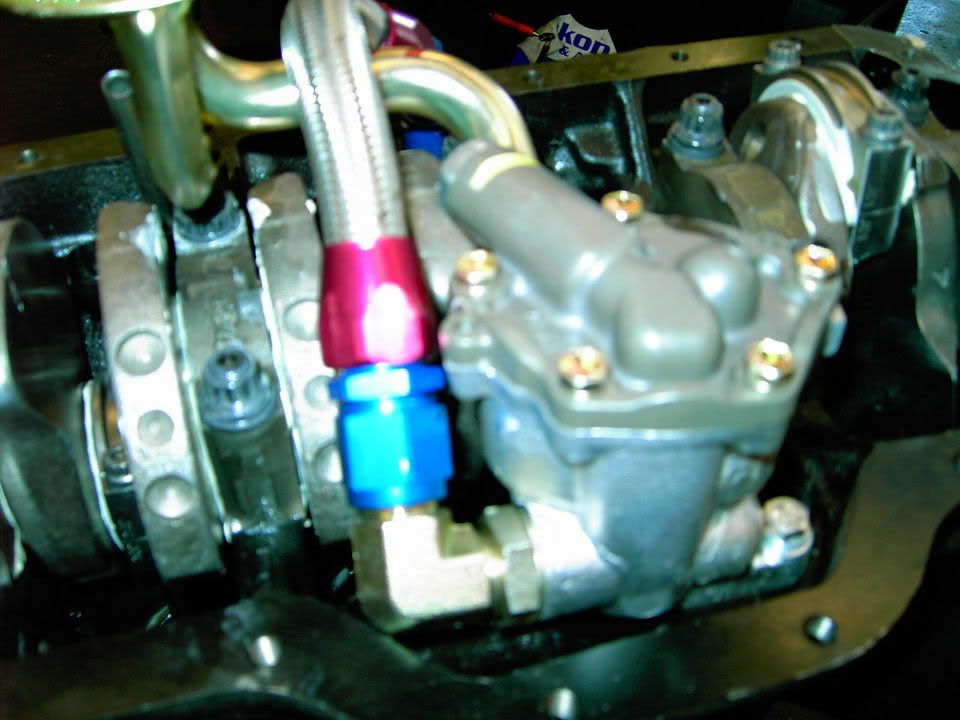

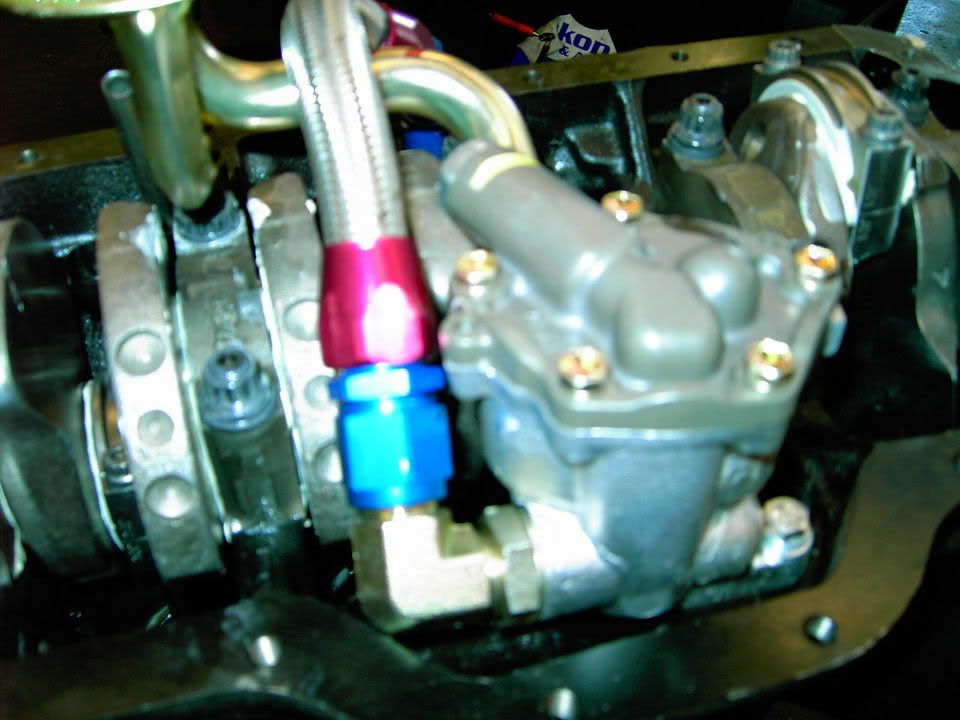

My system is AN10 from the pump to the return at the galley. I used Canton Mecca depth filter and 3 quart accusump. Also used a 1 quart Oil Guard bypass filter that takes oil out of the main galley, and filters it down to just one micron or better. (The Canton filters are claimed to be good down to 8 microns or better, and flow more dirty than a brand new paper pleated filter can.)

This gives you an idea of how convoluted the oil system can become if you let it take control of your engine build!

Small line is feed for turbo.

Two other small AN4 lines are oil supply from the main galley to the bypass filter, and the return line dumping oil back into the pan via the stock oil cooler dump port at the oil pan.

Then there is the AN10 line coming out of the engine, and the AN10 lines, one way valve, and T fitting allowing the accusump to fill/supply oil, and oil to go into the engine at the main galley. (Middle of the round filter boss on the engine is directly into the main galley that supplies oil to your entire engine, crank first.)

The thermostat works. I took mine apart, and re-tapped the stock sized fittings which were AN8 to AN10. (The stock ID in and out on the cooler.)

Same with the oil pump. I've modifed and ported my oil pump to accept AN10 fittings. (You can get BSP 18mm 90 fittings to AN10, but the ID of the fitting is not giving you full flow.) Same goes for the stock fitting on the filter side of the block. You have to drill and tap the block for a larger 20mm BSP to AN10 fitting, to get full ID maintained from the pump to the exit point on the block.

To keep the AN10 sized theme, we tapped and plugged the small drilled out passage that normally feeds the stock filter boss on the engine block. The stock main galley thread is 20mm, so a BSP to AN10 fitting works great there, no mods required.

I use a 1/2" NPT compression thread on the outlet where the NA cooler bypass would bolt up to the block. (The GTE has a simple block off plate there stock.) If I did it again, I'd go 20 BSP to AN10 as the straight threads of the bsp fitting don't stress the block like the 1/2" NPT ones do.

I broke a block using the 1/2NPT thread fitting on the rail port. (SUCKED FOR SURE< had to tear down the entire motor, and re-machine the block for a BSP20 to AN10.. Note how low mine is compared to stock which is at the oil pan rail height.)

Shimmed the pump with a 10mm nut, and two washers. Also ported the pump to smooth flow out of the pump. No sharp edges on the corners between the pump gears and the exit point into the 90 BSP fitting.

I don't know why there should be a problem using stainless line inside the pan. It's pretty rugged stuff, and should hold up to the heat and oil just fine.

My system is AN10 from the pump to the return at the galley. I used Canton Mecca depth filter and 3 quart accusump. Also used a 1 quart Oil Guard bypass filter that takes oil out of the main galley, and filters it down to just one micron or better. (The Canton filters are claimed to be good down to 8 microns or better, and flow more dirty than a brand new paper pleated filter can.)

This gives you an idea of how convoluted the oil system can become if you let it take control of your engine build!

Small line is feed for turbo.

Two other small AN4 lines are oil supply from the main galley to the bypass filter, and the return line dumping oil back into the pan via the stock oil cooler dump port at the oil pan.

Then there is the AN10 line coming out of the engine, and the AN10 lines, one way valve, and T fitting allowing the accusump to fill/supply oil, and oil to go into the engine at the main galley. (Middle of the round filter boss on the engine is directly into the main galley that supplies oil to your entire engine, crank first.)

Adjuster

Supramania Contributor

Thanks man!

I'll post some current photos when it's all done. (New and improved if you can belive it

And running the Maft Pro if all goes right.

I'll post some current photos when it's all done. (New and improved if you can belive it

And running the Maft Pro if all goes right.

Dude, I knew you were crazy!!! But he's right too, check his out. Notice the lip on the inside of this compression fitting leading into the block up to the oil filter inlet.

If I understood you correct, "Adjuster" this is the hole in the block to the right of the fitting in my hand. The objective was to remove any restrictions between the oil pump and the filter (because there are more than one correct?!?!)

The banjo bolt and this neck down in the compression fitting and the diameter of the bore going into the oil filter location. Oh and the inside diameter of the compression line is probably the same diameter too huh?

you drilled the block out and cracked it here correct?!?!? (DOH that would suck. My condolences go out to you) The scarafices we make in the name of horsepower and speed!!!

Im not sure I understood what you did if anything to this hole going back into the block from the oil filter adapter location. In the second photo, it seems that this hole would need modification too.

If I understood you correct, "Adjuster" this is the hole in the block to the right of the fitting in my hand. The objective was to remove any restrictions between the oil pump and the filter (because there are more than one correct?!?!)

The banjo bolt and this neck down in the compression fitting and the diameter of the bore going into the oil filter location. Oh and the inside diameter of the compression line is probably the same diameter too huh?

you drilled the block out and cracked it here correct?!?!? (DOH that would suck. My condolences go out to you) The scarafices we make in the name of horsepower and speed!!!

Im not sure I understood what you did if anything to this hole going back into the block from the oil filter adapter location. In the second photo, it seems that this hole would need modification too.

I noticed right after I posted and IJ alerted me to the fact that the ID of the tube is the exact same inside diameter, but if your changing it all I can see how gains could be made.

Edit:

Finally got around to checking my RX7 oil cooler, and sure enough it "IS" thermostatically controlled.

Edit:

Finally got around to checking my RX7 oil cooler, and sure enough it "IS" thermostatically controlled.

Last edited:

NashMan said:oh one more note you are not suppost to run braied line in oil there is one type of hose that cna be ran but ti not breaied

i going to be getting hard line made up this time around last time i drilled out the bago bolt as much as i chould befor but thsi time it hard line

what type? whats wrong with the braided?

i don't remmber just got to hydroilck shopa dn talk to some peoepl they will nto lead you the wroung way

as long as there not hick based shop

as long as there not hick based shop

Adjuster

Supramania Contributor

After much brainstorming, and trying to think out side the box, I was actually thinking of running the oil pump exit side straight out of the engine via the oil pan and a welded on bulkhead fitting, or drilling a hole through the block, and using a bulkhead fitting there... but really this is a nasty setup as there is not much free space inside the motor....

And then it hit me! The block is setup perfectly like it's own dry sump. You have the pump, and then the crossover pipe taper fitting that directs the oil up to the oil filter boss cast into the block.

That hole and fitting that ARZ's photo is where the oil after being pumped, goes up to the oil filter location. (Via a drilled passage that I belive is a restriction as the ID appears to be smaller than what I wanted, and smaller than the main galley fitting in the middle of the oil filter location.)

So, to keep the AN10 ID size from pump to return at the motor, the pump was modified, block was modifed and RX7 cooler was modified. Everything else was AN10 or better anyway.

I would use BSP type fittings v/s tapered thread ones to keep stress on the block to a minimum. (There is just enough material on the block to drill it out and tap it for the 20mm thread needed to keep the AN10 ID intact. And since the BSP type fitting should not crack the block, you just compress the o-ring and your done.)

On reflection, there is more material down where mine ended up as the "web" for the main also runs across there. By cutting down the mount, you get into the thicker web area, and you also lower your fitting height, and make it less of a reach to tap the passage to the oil filter so you can plug it.

I like the modified oil pans I have seen lately, and if I was building my motor now, I'd for sure add a round baffle, and kick out the one side at least. (Most likely kick out both sides, add the baffle, and a crank scraper/girdle as that lowers your oil pan, and adds even more capacity to your system along with the strenght of the girdle and it's built in scraper.

All it takes it money and a Mill does not hurt either... And an oven to cure your coatings in... oh, basicly it never ends, and eventually you get tired of spending the money and buy a 2006 FZ1 for your speed/power needs, and the Supra remains on jack stands, waiting for me to be interested in it again...

and a Mill does not hurt either... And an oven to cure your coatings in... oh, basicly it never ends, and eventually you get tired of spending the money and buy a 2006 FZ1 for your speed/power needs, and the Supra remains on jack stands, waiting for me to be interested in it again...

And then it hit me! The block is setup perfectly like it's own dry sump. You have the pump, and then the crossover pipe taper fitting that directs the oil up to the oil filter boss cast into the block.

That hole and fitting that ARZ's photo is where the oil after being pumped, goes up to the oil filter location. (Via a drilled passage that I belive is a restriction as the ID appears to be smaller than what I wanted, and smaller than the main galley fitting in the middle of the oil filter location.)

So, to keep the AN10 ID size from pump to return at the motor, the pump was modified, block was modifed and RX7 cooler was modified. Everything else was AN10 or better anyway.

I would use BSP type fittings v/s tapered thread ones to keep stress on the block to a minimum. (There is just enough material on the block to drill it out and tap it for the 20mm thread needed to keep the AN10 ID intact. And since the BSP type fitting should not crack the block, you just compress the o-ring and your done.)

On reflection, there is more material down where mine ended up as the "web" for the main also runs across there. By cutting down the mount, you get into the thicker web area, and you also lower your fitting height, and make it less of a reach to tap the passage to the oil filter so you can plug it.

I like the modified oil pans I have seen lately, and if I was building my motor now, I'd for sure add a round baffle, and kick out the one side at least. (Most likely kick out both sides, add the baffle, and a crank scraper/girdle as that lowers your oil pan, and adds even more capacity to your system along with the strenght of the girdle and it's built in scraper.

All it takes it money

Greg (or anyone else that has done this) is there a reason you went with a braided line on the pump output vs having a hardline made up using a threaded pipe fitting? I have some concerns over the hardening of the rubber over time being submerged in oil (both in and out) and cracking, leaking, etc; leading to a loss of pressure and then the motor.

Thoughts? or do you not anticipate the motor lasting long enough for that to be a problem...

Thoughts? or do you not anticipate the motor lasting long enough for that to be a problem...

Last edited:

I would think a semi-rigid hardline with swagelok fittings would be better (but more expensive).

http://www.swagelok.com

http://www.swagelok.com

That thought crossed my mind also. They are not cheap, but not really a huge price difference compared to AN fittings I geuss.3p141592654 said:I would think a semi-rigid hardline with swagelok fittings would be better (but more expensive).

http://www.swagelok.com

What do you mean by "semi" rigid?

http://www.swagelok.com/search/product_detail.aspx?part=SS-810-5-8

SS Swagelok Tube Fitting, 45° Male Elbow, 1/2 in. Tube OD x 1/2 in. Male NPT

Unit Price : 40.70

Availability : Call for Availability

http://www.swagelok.com/search/product_detail.aspx?part=M-810-2-8

Swagelok Tube Fitting, Male Elbow, 1/2 in. Tube OD x 1/2 in. Male NPT

Price: USD 34.50

Availability: Call for Availability

an fittings for $ comparison

http://store.summitracing.com/partdetail.asp?autofilter=1&part=AER%2DFBM4024&N=700+115&autoview=sku

http://store.summitracing.com/partdetail.asp?autofilter=1&part=AER-FBM2009&N=700+115&autoview=sku

Great writeup btw. Very good info in here. I'm glad to finally find pics of the group A ban baffling.

There is a swagelok distributer over in Sunnyvale that I'll try to check out next week. I'll see if they have something that makes 'sense' to use.

I'm going to look into having a hard line made up with a pipe fitting on the pump end and then change the output on the pump (similar to what Greg did). Personally, a hard line vs a hose makes me feel a bit more comfortable. If I was pulling the pan on a regular basis, that would be different, but since I'm not, I would rather not worry at all.

I'm going to look into having a hard line made up with a pipe fitting on the pump end and then change the output on the pump (similar to what Greg did). Personally, a hard line vs a hose makes me feel a bit more comfortable. If I was pulling the pan on a regular basis, that would be different, but since I'm not, I would rather not worry at all.

Great thread!

Couple comments

" wether you are using the 5m or 7m pump, there is a clearance from the gears, to the lower case. there is a minimum and maximum tolerance. what you need to do is measure that, and then have the cover machined at the machine shop to put this as close to the minimum clearance as posible"

Machining the cover won't reduce the clearance as the cover is "flat". you would have to machine the pump body itself. Odds are you'd be better off replacing an out of spec pump than trying to "fix" it.

"the pressure releif spring wears as well...this is a linear spring, so it does open before max presure is realized...it starts being compressed the moment any pressure is applied and is fully open by the max oil pressure"

I don't agree that the springs (pump relief and squirters) are "wearing" they may relax some with age, but it's not hard to design a spring to perform the same over a long long time if done right. I doub't you'd see much difference between an new and used spring, if you do the designer should be fired. Also, the spring doesn't open immediately, the reson why is that it is preloaded. The same thing adding shims does. It increases the cracking pressure. The free length of the spring is longer than the length when it is installed so it has some static force on it keeping the ball forced closed. You have to have enough pressure to overcome that force before the valve will open at all. Good call on the squirter springs though, I've seen a few with metal shavings stuck in the springs (machinist must not have removed them before flushing the galley) at least inspect them carefully.

I'd be nervous about the stainless hose in the oilpan. You have to make sure that braided lines aren't touching anything or they will wear right into it. As for the swagelock stuff there's no reason to get that fancy, if you want hardlines just use an AN tube nut and flare the tubing. Hhmm, that would be a pretty nice product if you got a batch CNC bent and put all the fittings together as a kit.

Glen

Couple comments

" wether you are using the 5m or 7m pump, there is a clearance from the gears, to the lower case. there is a minimum and maximum tolerance. what you need to do is measure that, and then have the cover machined at the machine shop to put this as close to the minimum clearance as posible"

Machining the cover won't reduce the clearance as the cover is "flat". you would have to machine the pump body itself. Odds are you'd be better off replacing an out of spec pump than trying to "fix" it.

"the pressure releif spring wears as well...this is a linear spring, so it does open before max presure is realized...it starts being compressed the moment any pressure is applied and is fully open by the max oil pressure"

I don't agree that the springs (pump relief and squirters) are "wearing" they may relax some with age, but it's not hard to design a spring to perform the same over a long long time if done right. I doub't you'd see much difference between an new and used spring, if you do the designer should be fired. Also, the spring doesn't open immediately, the reson why is that it is preloaded. The same thing adding shims does. It increases the cracking pressure. The free length of the spring is longer than the length when it is installed so it has some static force on it keeping the ball forced closed. You have to have enough pressure to overcome that force before the valve will open at all. Good call on the squirter springs though, I've seen a few with metal shavings stuck in the springs (machinist must not have removed them before flushing the galley) at least inspect them carefully.

I'd be nervous about the stainless hose in the oilpan. You have to make sure that braided lines aren't touching anything or they will wear right into it. As for the swagelock stuff there's no reason to get that fancy, if you want hardlines just use an AN tube nut and flare the tubing. Hhmm, that would be a pretty nice product if you got a batch CNC bent and put all the fittings together as a kit.

Glen

any one know where I could buy a copy of Group A magnesium oil pan?

I didn't want make a new topic so I've posted in this one

I didn't want make a new topic so I've posted in this one

QWIKSTRIKE

475rwhp459torq an climbin

drjonez said:arnout over in the netherlands makes a girdle and a windage tray IIRC....if a scraper isn't your thing.

IMNSHO the #1 fix is the stupid oil filter mount....next to a properly rebuilt engine, of course.

I concur with the good DR

QWIKSTRIKE

475rwhp459torq an climbin

supra87t/t4 said:Great thread!

Couple comments

" wether you are using the 5m or 7m pump, there is a clearance from the gears, to the lower case. there is a minimum and maximum tolerance. what you need to do is measure that, and then have the cover machined at the machine shop to put this as close to the minimum clearance as posible"

Machining the cover won't reduce the clearance as the cover is "flat". you would have to machine the pump body itself. Odds are you'd be better off replacing an out of spec pump than trying to "fix" it.

"the pressure releif spring wears as well...this is a linear spring, so it does open before max presure is realized...it starts being compressed the moment any pressure is applied and is fully open by the max oil pressure"

I don't agree that the springs (pump relief and squirters) are "wearing" they may relax some with age, but it's not hard to design a spring to perform the same over a long long time if done right. I doub't you'd see much difference between an new and used spring, if you do the designer should be fired. Also, the spring doesn't open immediately, the reson why is that it is preloaded. The same thing adding shims does. It increases the cracking pressure. The free length of the spring is longer than the length when it is installed so it has some static force on it keeping the ball forced closed. You have to have enough pressure to overcome that force before the valve will open at all. Good call on the squirter springs though, I've seen a few with metal shavings stuck in the springs (machinist must not have removed them before flushing the galley) at least inspect them carefully.

I'd be nervous about the stainless hose in the oilpan. You have to make sure that braided lines aren't touching anything or they will wear right into it. As for the swagelock stuff there's no reason to get that fancy, if you want hardlines just use an AN tube nut and flare the tubing. Hhmm, that would be a pretty nice product if you got a batch CNC bent and put all the fittings together as a kit.

Glen

I agree Glen...This IMHO is just an itch for issues that need not be addressed if a larger pipe can be made. Go to an aeroquip shop...they have made me hard pipes like this for my new turbo

anyone found out the thread needed on the 7m block yet where the oil enters from the oil pump? i have a 7m block torn down now and dont want to take the whole thing tot he hydralic line shop to get the right fittings. lol. i figure someone may have found this out already. if not ill be sure to post it when i find out.