I hope that it will hold up to use...atmperformance;1970351 said:I like that CF hatch

Race Ready 7M

- Thread starter Van

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I'll be checking back to see how it's holding up. i might need one myselfVan;1970363 said:I hope that it will hold up to use...

1986.5supra_kid

Rice? No its Corn (E85)

Van- Id like to know what you find on the seam stitching . ive read that the car should be on jacks and others say its fine just to weld the car as it sits. then there is those that tig or mig and then the length of the seams and bracing of the car so the heat doesnt warp. im probably making a mountain of mole hill tho.

I'll be talking to members of the racing club I belong to to get a better idea on which process is most effective, and I'll post it here.1986.5supra_kid;1970382 said:Van- Id like to know what you find on the seam stitching . ive read that the car should be on jacks and others say its fine just to weld the car as it sits. then there is those that tig or mig and then the length of the seams and bracing of the car so the heat doesnt warp. im probably making a mountain of mole hill tho.

IJ... Got any suggestions; MIG or TIG?

I'm also going to look into using extruded, rectangular, aluminum tubing in place of the steel on both of the cross members on the front end. Those are the front cross member and sub frame cross member.

1986.5supra_kid

Rice? No its Corn (E85)

i remember looking at a subaru that was mig and a ae86 that was race ready with mig welds. i just didnt know if its because tig welding is a art where a monkey like me can run a mig.

http://www.supramania.com/forums/member.php?11021-Flateric

Flateric on here w/ a '90 targa street car claims a curb weight of 3,000lbs one of the mods was custom crash supports... I was think of looking into that as well... I'd be interested if you came up with any advice for seam welding too, although I always figured it just entailed welding panels completely together where they are spot welded....

one of the mods was custom crash supports... I was think of looking into that as well... I'd be interested if you came up with any advice for seam welding too, although I always figured it just entailed welding panels completely together where they are spot welded....

almost forgot to ask... "turning" the coil? is that just twisting it a bit more?

Flateric on here w/ a '90 targa street car claims a curb weight of 3,000lbs

almost forgot to ask... "turning" the coil? is that just twisting it a bit more?

As someone who has stitch welded cars before I can tell you there's usually very little issue with warping from heat as the stitch welding is slow. I've never done a supra, mostly nissans S13s and S14s and a z30. for the center sections of the car we would remove stresses by jacking up the middle to take some tension off but the wheels would still be on the ground. just don't try to leave interior in it will get hot enough to set your roof liner on fire. I'd talk more but i'm still at work right now.

most seem welding is done by mig so you can stitch weld it and mig also introduces less heat into the metal than tig. runs of 1-2ft can be done at a time to prevent any heat warping. the big thing to look for when doing this is having the chassis straight. I've seen rally teams weld up chassis on rotisseries but they usually have jigs. For most seem welding you're really trying to get the car to rest straight with no twist because if you weld it into place with a twist that's going ot stay there forever. also there's a limit too how stiff you can go, i remember ford tearing apart chassis by making them too rigid. There's also a lot of prep work if your car has the rubbery seem sealer which will need to be removed before welding. A S13 would take anywhere from 40-50hours of work to do the whole thing but the results were great, shutting the door sounded like a merchandises rather than a sheet metal shed. if you have any questions feel free to shoot me a PM

Mig and CrissCross back and forth across the chassis, bit like torquing a head, as ATM says important to make sure it's as straight as possible before you start, good wheel alignment guy should be able to tell you if it's got a twist to it, Most Mk3's don't unless they've been hit hard of have had 500+rwhp for 13+ yearsVan;1970413 said:I'll be talking to members of the racing club I belong to to get a better idea on which process is most effective, and I'll post it here.

IJ... Got any suggestions; MIG or TIG?

I'm also going to look into using extruded, rectangular, aluminum tubing in place of the steel on both of the cross members on the front end. Those are the front cross member and sub frame cross member.

I did the numbers on Aluminium Subframes and to get them stong enough they weren't going to save a lot of weight so I didn't go ahead.

good to know as well... would any chassis reinforcement, or a cage have reduced the amount of twist your car had after that much use?

Seam welded and a good cage would have prolonged it's service life for sure, a lot of the twist was because it was a Targa Car so had lousy torsional ridgidity to begin with.Insidious Surmiser;1970663 said:good to know as well... would any chassis reinforcement, or a cage have reduced the amount of twist your car had after that much use?

This is really great info. Thanks IJ and ATM. I'll pass this along to VIP Performance.

I dropped off the car Monday to start the lightening process. The cross member under the radiator will be replaced w/ chrome-moly tubing, the front and rear bumpers replaced w/aluminum in the stock form. Today the hood/bonnet and hatch are replaced with carbon fiber, and the glass on the quarter windows and the hatch, replaced w/polycarbonate. There will be photos of the process and progress done at VIP.

I dropped off the car Monday to start the lightening process. The cross member under the radiator will be replaced w/ chrome-moly tubing, the front and rear bumpers replaced w/aluminum in the stock form. Today the hood/bonnet and hatch are replaced with carbon fiber, and the glass on the quarter windows and the hatch, replaced w/polycarbonate. There will be photos of the process and progress done at VIP.

Oh, ok. That makes sense. I'm in the process of swapping my engine out of my targa and into a hardtop ATM 8)IJ.;1970673 said:Seam welded and a good cage would have prolonged it's service life for sure, a lot of the twist was because it was a Targa Car so had lousy torsional ridgidity to begin with.

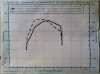

At this time, I'm planning to move the motor back four inches and down an inch to place more weight in the middle of the car and lower the center of gravity. Additionally, I plan to move the seats back four inches and the pedals, as well as the steering wheel. Has anyone else modified their car this way?

This will necessitate moving the engine and transmission mounts, the fire wall, transmission tunnel and extending the intake tube. There maybe a need to extend some of the wire harness. Then the exhaust and drive shaft will be shortened.

This will necessitate moving the engine and transmission mounts, the fire wall, transmission tunnel and extending the intake tube. There maybe a need to extend some of the wire harness. Then the exhaust and drive shaft will be shortened.

Last edited:

Van I'm thinking about running 9.3:1 compression with my 1.4mm headgasket on the 7m I just rebuilt.

I love the responsiveness of a higher compression engine. Boosting to 10psi to get a quick car and at 13psi boosting for max WHP/Tq on the CT26 w/a stock wheel (319/331).atmperformance;1974135 said:Van I'm thinking about running 9.3:1 compression with my 1.4mm headgasket on the 7m I just rebuilt.

Attachments

Last edited:

I'm looking forward to the throttle response and the shock on peoples' faces when they see what a stock ct26 can do under higher compression conditions. Later i can drop down to 8.88:1 with a 2mm headgasket if i ever get the need for more boost.

2013 expenses

new wheels and tires $1,300.00

new front brakes $1,130.00

new exhaust $440.00

aluminum bumpers

carbon fiber hood $587.00

carbon fiber hatch $616.00

polycarbonate windows

chrome molly tubing cross members

brake pads $90.00

brake rotors $296.00

professional fabrication

As promised, that is what I've spent on the weight reduction program so far...

new wheels and tires $1,300.00

new front brakes $1,130.00

new exhaust $440.00

aluminum bumpers

carbon fiber hood $587.00

carbon fiber hatch $616.00

polycarbonate windows

chrome molly tubing cross members

brake pads $90.00

brake rotors $296.00

professional fabrication

As promised, that is what I've spent on the weight reduction program so far...

Last edited:

![david[5].jpg](/data/attachments/43/43065-77d6b51a5cb330e45b0b3240a7654414.jpg)