Just had the wonderful experience of pulling my rear speaker pods out to place new ones in, while doing so i noticed that my rear wheel well is in much worse shape than i thought I'm capable of fabricating the panels myself and putting them in, but i'd rather save myself time and headache by buying patch panels if they exist. I wasnn't able to find any at first glance with a google search, but hopefully somebody here can point me in the right direction. i have pics if anybody wants to see

Rust issues/ And repairs :)

- Thread starter Chaingun

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sir, your going to have to cut your car in order to remove the cancer, just replace with a box of diamond plate etc., No need for pics as we all know the hazards of spare tire well rust. Just cut it out. C:

unfortunately it's not just the spare tire well, there's only one spot there, i have to replace almost all of my driver side wheel well, and a good portion of the passenger as well. I'm most likely going to cut it all out, make my patch panels, then rhino line every square inch of the underside of the car, theres no rust in any structural points, just the wheel wells. If all goes well i can repair most of it with custom made panels, then the rest with fiberglass and body filler. It's going to be a test of all my creative skills

If you have the time, money, and resources I say go for it. I suggest laying down some por-15 after making all the patches.. that paint is incredibly tough!

Sent from my DROIDX using Tapatalk

Sent from my DROIDX using Tapatalk

Thanks for the encouragement everyone, i've removed all of the bad metal, and i'm prepping to put the new panels i've fabbed up in, before i continue can anyone tell me where to get POR15, i know it's pretty much just phosphoric acid paint, and also can it be welded though, IE paint all of the surfaces before I weld it together? I'm also going to be treating the area with either underbody coating or rubber roofing tar to prevent this from happening again, though this car won't see another winter here so i doubt it will  Any recommendations on what type of coating to use?

Any recommendations on what type of coating to use?

I've given up on my rusty shell. Spent all winter cutting and welding only to find the rust in every enclosed area I opened up. finally realized (about 6 months too late) that no matter how much I fix, I won't be able to get it all. As I'm sure you know, if you don't get it all, you might as well not even bother. Good luck...mine got the best of me, and I consider myself rather patient when it comes to rust repair. I don't know what they did to treat these cars at the factory, but whatever it was, it sucked.

Throw up some pics when you get a chance...would love to see how you're going about it all.

SGinNE

Throw up some pics when you get a chance...would love to see how you're going about it all.

SGinNE

I've seen cars in much worse shape come back, my rust issues are nearly completely confined to the rear wheel wells with a small among of surface rust in a few small spots.

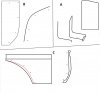

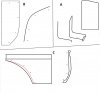

Here's the process that I will be using to repair the area, as well as current pics.

Starting by cutting out all of the rust in the wheel wells and removing the factory undercoating. Then I'll be masking off the area and sand blasting every inch of it to get a clean surface. The area will be treated with POR15 after welding to ensure that the rust stays gone on the inside. I'm removing almost the entire rear half of the wheel well and replacing it with a solid piece of 20 gauge metal (B). in the very center of the wheel well there is still good metal, and over that after it's sand blasted and treated I'll be welding in a thicker 16 gauge support piece (A), as it appears that area is a structural support. Once the support is welded in and the rear half of the well is attached I'll be applying the new outer skin to the roll pan (C). This is going to be 20 gauge metal as well. Treated and painted on the back side. Once all three of those pieces are in, I can weld the new front corners of the wheel well in.

In our cars we're fortunate that all of the area that tends to rust out is covered either by the bumper, or the ground effects. That means that I can concentrate on the strength and durability of the repair, as opposed to how it looks. After the new metal is welded in, I'll be using Fiberfill to restore the edges shape of the wheel well. This is probably the hardest part for me because i can never mix the hardener in the right amount. After these repairs are done, I'll be taping off the outer edge of the well and applying several coats of rubberized coating to the entire wheel well, after thoroughly drying the area and prepping it with a bonding agent. I've also been toying with the idea of adding a drain in the rear section in case of leaks from the hatch seal, and I'd be glad to hear any thoughts on that, this would be in the area of the rear quarter panel under the antenna and it's opposite side.

If all goes well perhaps I can supply the templates i created to someone that can produce them in larger numbers or on an as needed basis. I'll be coming back with new pics as the project continues. You can see below the shape it's in before I removed the old rusty material, as well as the plans for the new parts, which I've started cutting already Metal band saw ftmfw.

Metal band saw ftmfw.

Here's the process that I will be using to repair the area, as well as current pics.

Starting by cutting out all of the rust in the wheel wells and removing the factory undercoating. Then I'll be masking off the area and sand blasting every inch of it to get a clean surface. The area will be treated with POR15 after welding to ensure that the rust stays gone on the inside. I'm removing almost the entire rear half of the wheel well and replacing it with a solid piece of 20 gauge metal (B). in the very center of the wheel well there is still good metal, and over that after it's sand blasted and treated I'll be welding in a thicker 16 gauge support piece (A), as it appears that area is a structural support. Once the support is welded in and the rear half of the well is attached I'll be applying the new outer skin to the roll pan (C). This is going to be 20 gauge metal as well. Treated and painted on the back side. Once all three of those pieces are in, I can weld the new front corners of the wheel well in.

In our cars we're fortunate that all of the area that tends to rust out is covered either by the bumper, or the ground effects. That means that I can concentrate on the strength and durability of the repair, as opposed to how it looks. After the new metal is welded in, I'll be using Fiberfill to restore the edges shape of the wheel well. This is probably the hardest part for me because i can never mix the hardener in the right amount. After these repairs are done, I'll be taping off the outer edge of the well and applying several coats of rubberized coating to the entire wheel well, after thoroughly drying the area and prepping it with a bonding agent. I've also been toying with the idea of adding a drain in the rear section in case of leaks from the hatch seal, and I'd be glad to hear any thoughts on that, this would be in the area of the rear quarter panel under the antenna and it's opposite side.

If all goes well perhaps I can supply the templates i created to someone that can produce them in larger numbers or on an as needed basis. I'll be coming back with new pics as the project continues. You can see below the shape it's in before I removed the old rusty material, as well as the plans for the new parts, which I've started cutting already

I think you've got a basic understanding of what's involved, but I don't think you appreciate how far that rust can hide inside the complex curves of the gas fill area, in the rockers, and up into the rear subframe rails. I commend your enthusiasm however and wish you the best. For the record, the car I just sent to the scrapper was (on the surface), far less rusty than the one you're attempting to repair. I can only hope you don't spend 6 months wasting material, welding gas, and time trying to fix the unfixable like I did. Good luck, and please post more pictures as you make progress.

SGinNE

SGinNE

I do understand mostly because i've seen in already, my driver side is cut clean and will be sand blasted by the weekend. i'm looking for a source of phosphoric acid or POR15 before i start welding in the new panels, i'll provide pics once the sandblasting is done. My car looks very bad in the pics, but the areas you see rusted, at least in the rear of the well, are all of the rust that is there. It's odd that the filler neck in my car has very little to no rust around it, even after wire brushing it there was none except on the surface of the metal, in my car it's all confined to nonstructural areas IE the wheel wells which are going to be like a tank after I'm done  Thank you for the encouragement though, it's been a few years since I've done major rust restoration like this

Thank you for the encouragement though, it's been a few years since I've done major rust restoration like this

Just as an FYI, every area I found with surface rust had significant rusting on the opposite side of the effected panel. I didn't at first consider surface rust to be much of an issue, but when I realized that all surface rust needed to be cut out as well the scope of the project doubled. Might have just been my particular case, but I've seen it before on other cars too, so possibly not.

I agree, each car is a case by case basis, but the scope of the project doesn't bother me, after finding out how bad the rear wells are and a thorough inspection later I know that this car can be saved. As time goes on the MK3 will be getting more and more rare, especially if ones like mine that are salvageable are sent to the scrap yard. This repair and the car in general is a challenge to my skills as both a mechanic, and a body-man, and I'm stubborn enough that i don't back down from a challenge no matter what it costs me. I'll keep pics posted, unfortunately I pulled out my MIG and it's not striking a good arc on the metal I'm using, I have have to bust out my gasless MIG welder and give it a shot, it may not be as pretty but i can still make a damn strong weld with it.

I'm sure you've already discovered that every seam has a sealer between the layers that makes welding impossible. I'd be willing to bet money your welds are coming out poorly because you're hitting sealer. I had to cut every spot weld in effected areas and remove each layer of sheetmetal down to good steel (or down to nothing most of the time), then start building back up one layer at a time. You can't just cut through 3 layers of spot welded steel expecting to get a good result. If there were three pieces that made up a section of the inner fender, you need to take all three layers out, and make 3 new pieces to weld back in the correct order.

Now you can see why I gave up.

Now you can see why I gave up.

Your right that sealer is a bitch, what i can get to with a grinder has been removed with a 3m scotch brite wheel, i haven't found any spots where it was 3 layers thick that i need to replace, but i'm sure it's there, probably in the front of the wheel well. I'm going into this with full knowledge that it's going to be difficult, but i'll have a lasting repair when i'm done

The seam in between the two halves of the wheel wells is completely full of seam sealer, its not just on the outer edge. If you get inside the car and start cutting spot welds, you'll see what i mean.

That's not needed on the driver side, the rust stops before it gets to the middle of the well, the plate i'm putting in will be covering from about the middle to the outside on the drivers side, and it will be lipped to give a better area to weld to the new outer skin