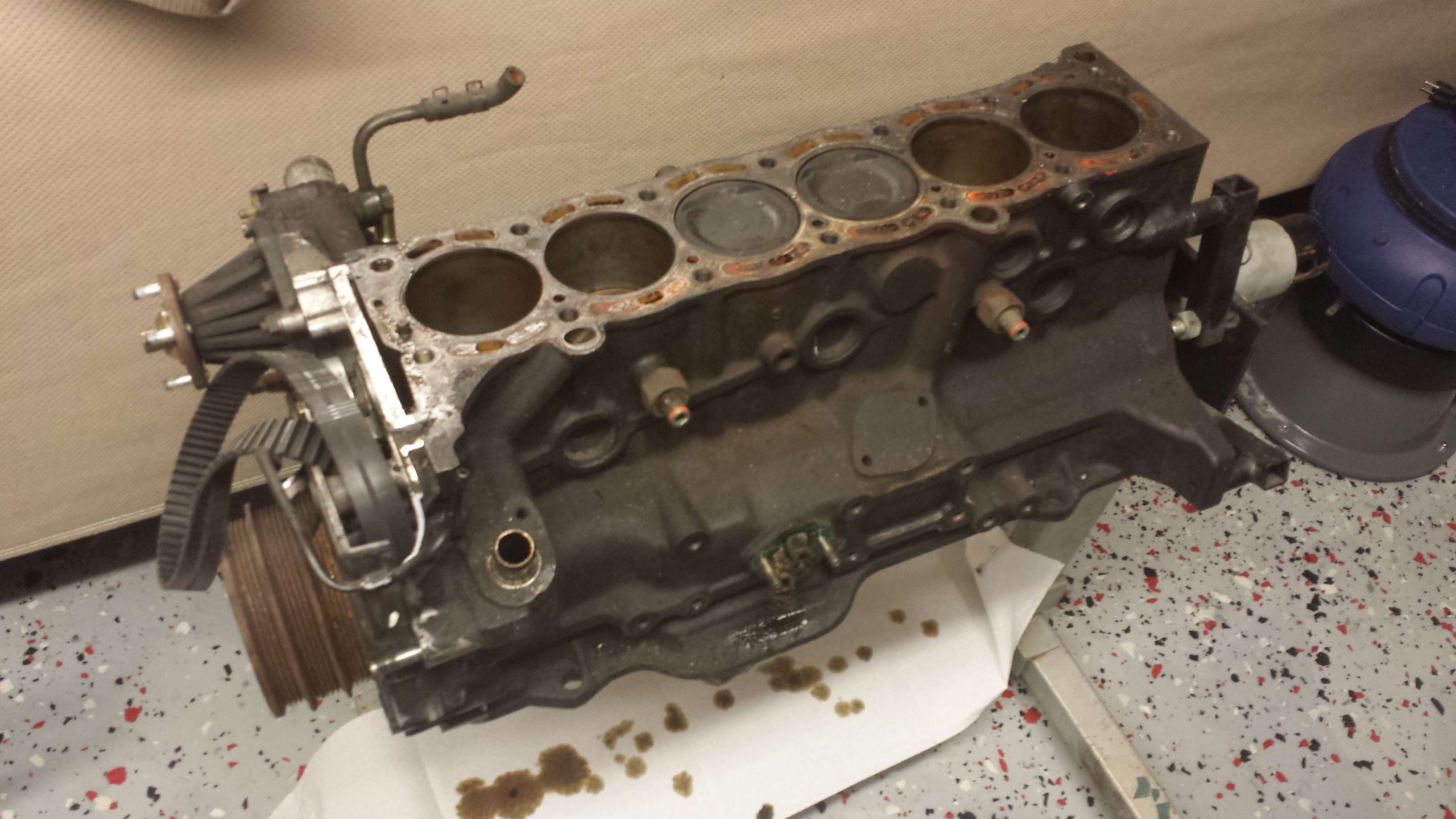

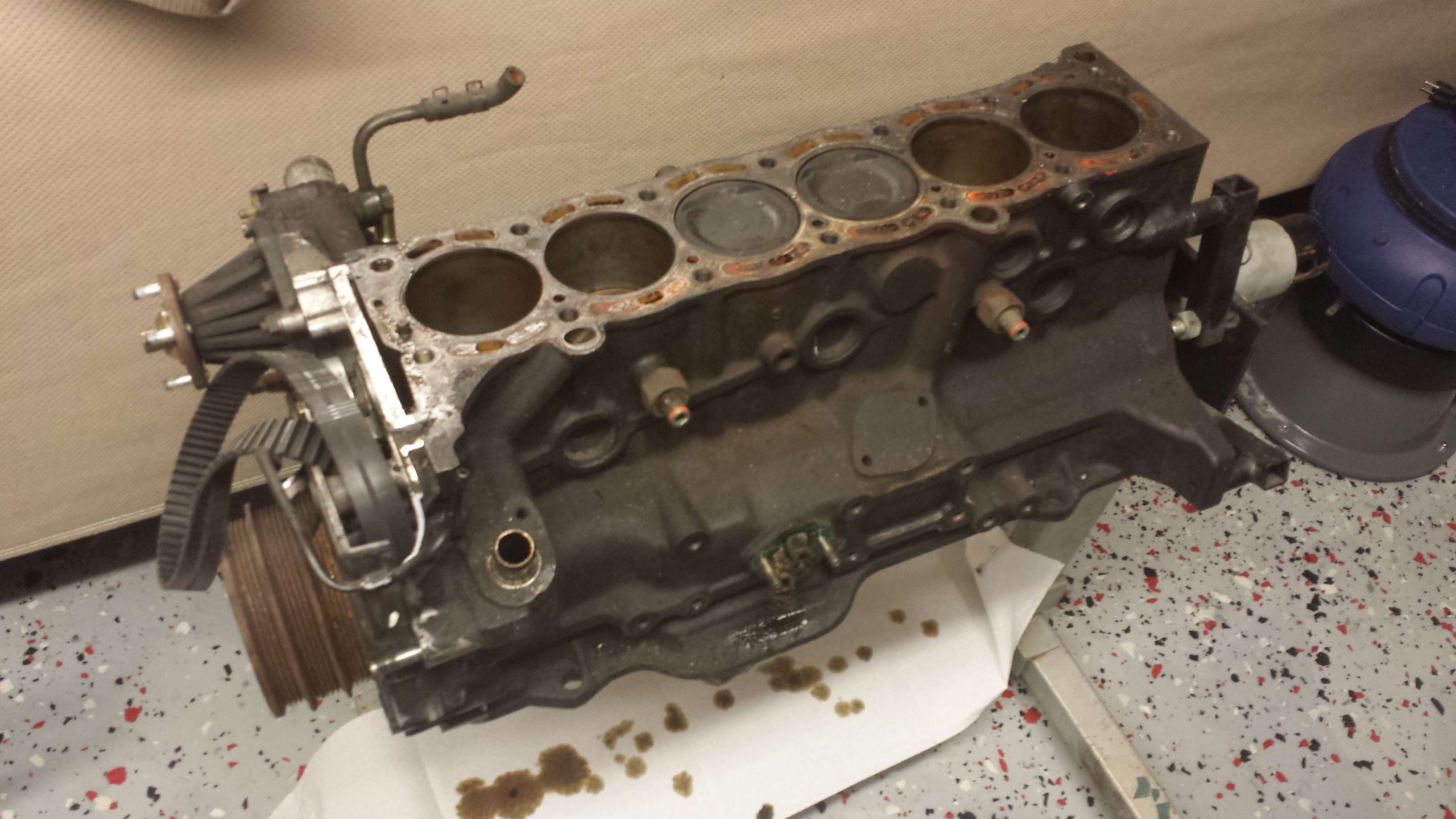

Engine block machine work has started. Engine lab will be doing the following

- clean & inspect block

- resurface block

- install billet mains and line bore/hone

- torque plate bore/hone to fit .5mm o/s forged pistons

- replace oil pump driveshaft bearings

- polish oil pump driveshaft journals

- polish crankshaft

- precision race balance assembly

The race balance alone is $540 with a discount they gave me :icon_surp

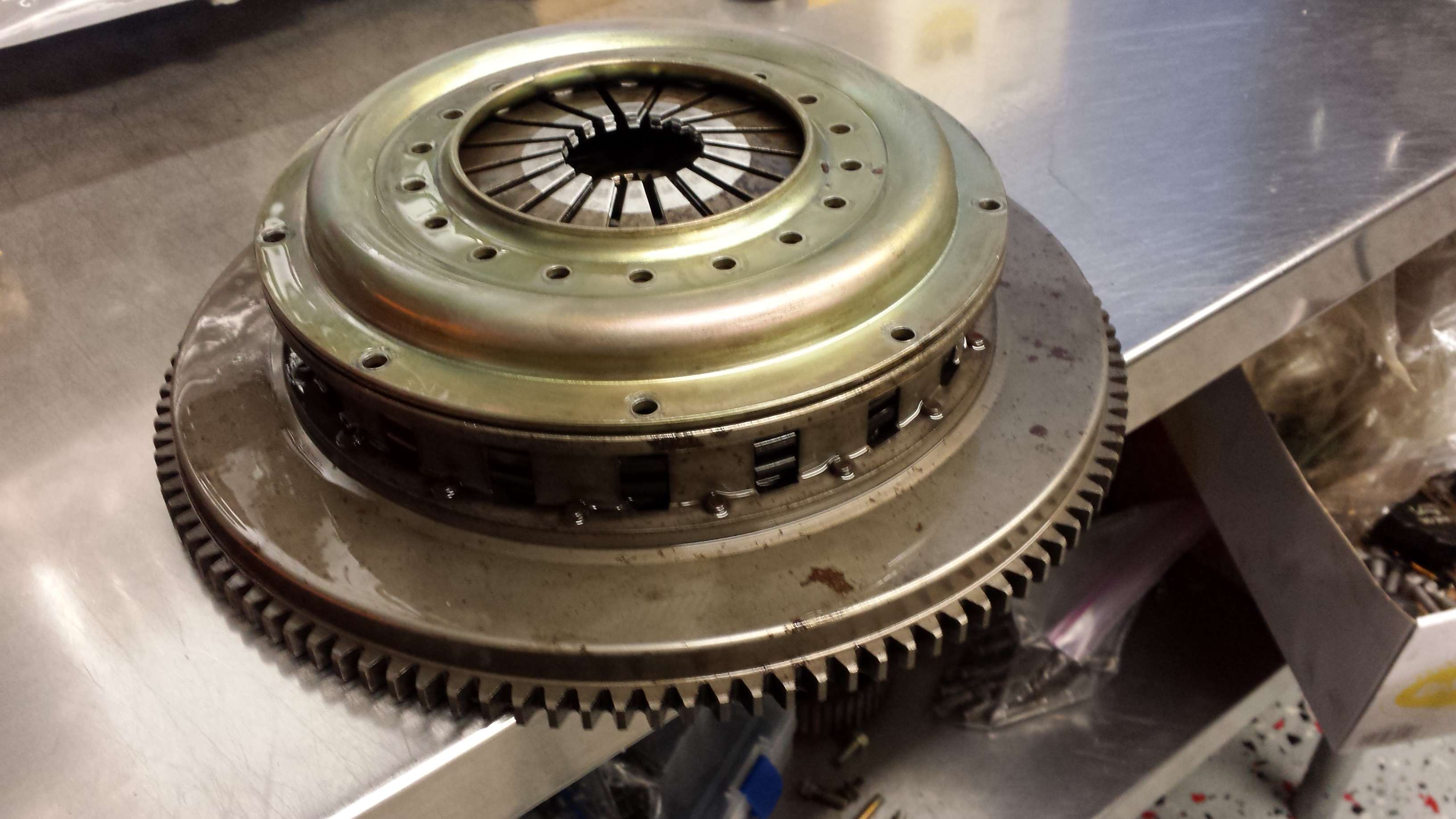

Also, i bought an os giken triple plate clutch. it's on its way. Engine Lab needs the crank, a piston, a rod, crank damper and clutch to do the race balancing.

gonna spend the weekend boxing up my r154 to be sent to Marlin Crawler for a full build

Meanwhile im fiddling with the turbo setup ill be using. Drewgo manifold, s366 borg warner, precision 44m wg. I will probably be running the sound performance quick spool valve as well. I was going to build a custom manifold but decided I didnt want to deal with it and for my power goals the drewgo is enough.