righto after latest round of tuning it has become apparent that my HG is leaking under heavy load. normal driving conditions normal.

So stating up this thread to gain opinions to settle this once and for all head will being pulled off as soon as the new gasket turns up from driftmotion will take a couple weeks id say.

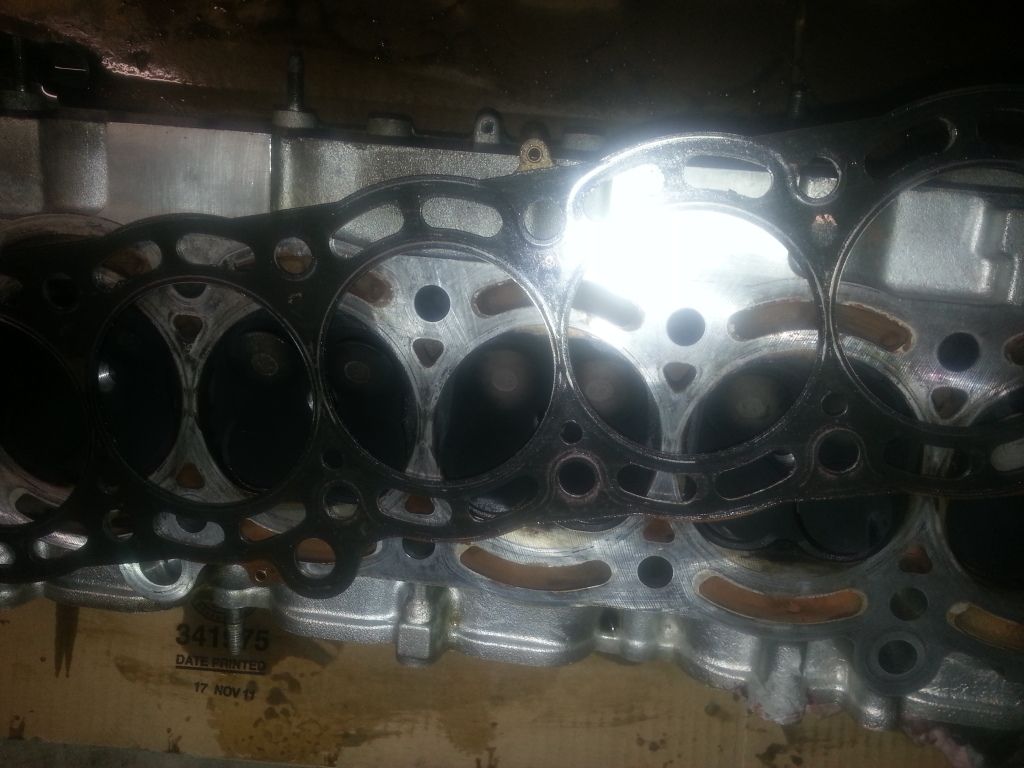

Will be putting up photos to try diagnose why its happened.

Here is my headgasket story

1. just bought car was probly already blown lasted 6 days blew big time

2. did full rebuild no research reused stock bolts was all good till upped the boost and blew

3. Used Arp gear stock HG never blew

4. Went for forged bottom end so changed to a cometic HG didn't even start the car only cranked and filled the sump with coolant the dowels in the block looked rubbish

5. Got another brand new cometic HG changed dowels (this is current HG) been driving for 2 years on the track it got hot really quick and on hills would push coolant got retuned for more power and it cant handle the incresed boost low boost still fine just under heavy load it leaks

At the time I went to MHG head and block were machined to an RA of less than 20 were the instructions I gave to the shop and the front cover was machined too

ARP studs with ARP lube used

But on the latest one it looks like the shop that put my head on may have used copper spray on the new cometic HG maybe that is my issue

Head was hardness checked at HG no 2 and no 3 will be getting it checked again once I pulled the head this will be a semi slow moving thread but Ive had enough of HG's and want to enjoy the power of my new tune 422rwkw would have been more but had to stop as the HG problem becoming obvious previously it was a hunch

So stating up this thread to gain opinions to settle this once and for all head will being pulled off as soon as the new gasket turns up from driftmotion will take a couple weeks id say.

Will be putting up photos to try diagnose why its happened.

Here is my headgasket story

1. just bought car was probly already blown lasted 6 days blew big time

2. did full rebuild no research reused stock bolts was all good till upped the boost and blew

3. Used Arp gear stock HG never blew

4. Went for forged bottom end so changed to a cometic HG didn't even start the car only cranked and filled the sump with coolant the dowels in the block looked rubbish

5. Got another brand new cometic HG changed dowels (this is current HG) been driving for 2 years on the track it got hot really quick and on hills would push coolant got retuned for more power and it cant handle the incresed boost low boost still fine just under heavy load it leaks

At the time I went to MHG head and block were machined to an RA of less than 20 were the instructions I gave to the shop and the front cover was machined too

ARP studs with ARP lube used

But on the latest one it looks like the shop that put my head on may have used copper spray on the new cometic HG maybe that is my issue

Head was hardness checked at HG no 2 and no 3 will be getting it checked again once I pulled the head this will be a semi slow moving thread but Ive had enough of HG's and want to enjoy the power of my new tune 422rwkw would have been more but had to stop as the HG problem becoming obvious previously it was a hunch