i normally dont post pics of my car but i was too excited not to share.

this was the design i came up with. i wanted a lot of volume, even in the rear. i wanted the throttle body to come in at an angle so it faced towards the runners for better flow. i also wanted a square design w/ short runners as this proved to be a good design on sean's car. i think all things were acomplished. just want to say thanks again to sean for making my vision a reality. i think he did an awesome job. cant wait to see what it will do.

concept-

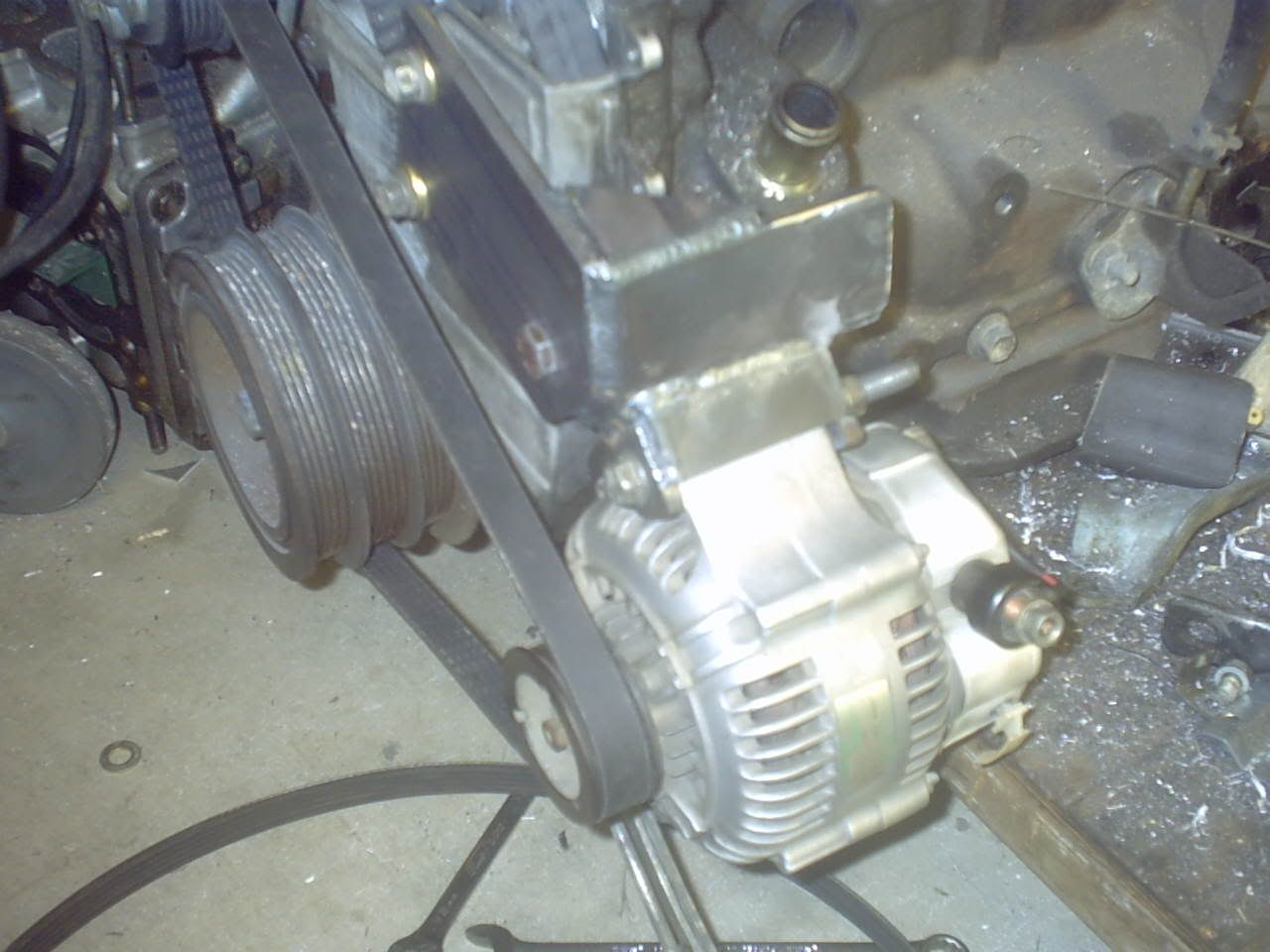

end result-

this was the design i came up with. i wanted a lot of volume, even in the rear. i wanted the throttle body to come in at an angle so it faced towards the runners for better flow. i also wanted a square design w/ short runners as this proved to be a good design on sean's car. i think all things were acomplished. just want to say thanks again to sean for making my vision a reality. i think he did an awesome job. cant wait to see what it will do.

concept-

end result-