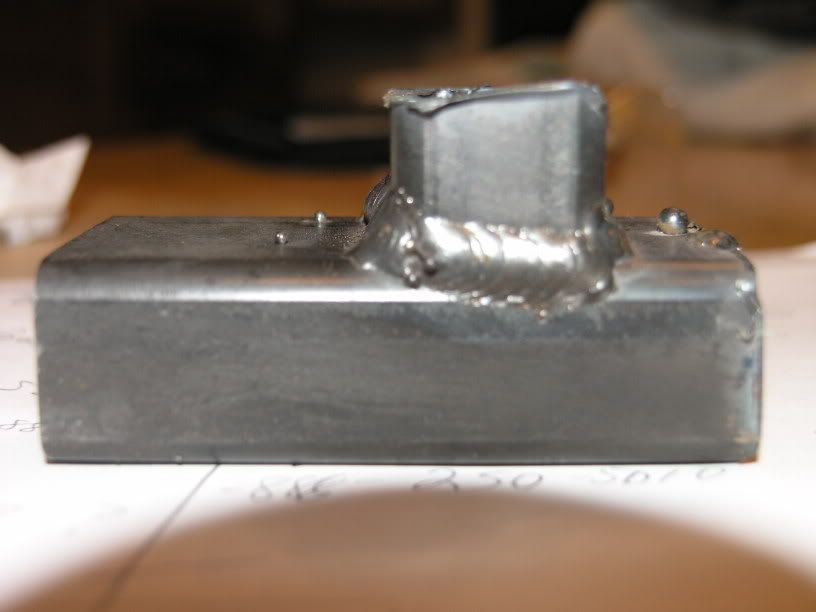

Get 2 rectangular pieces of 6mm thick plate (ie 60mmX100mmx6mm) Hold one up at a 90deg so it forms a T. Make sure you clean up/linish/grind the surface smooth and clean. Also put a slight bevel on 1 side that is going to get welded.

Tack the ends and square it up to a 90deg. If you feel like your tacks are going to break then put a couple stiches on the back to hold its shape. Try not to tack the side where you bevelled.

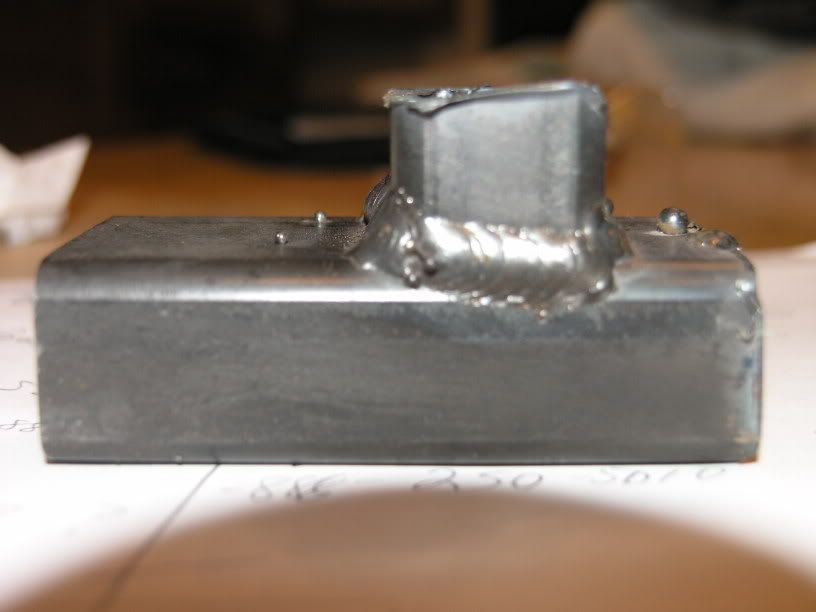

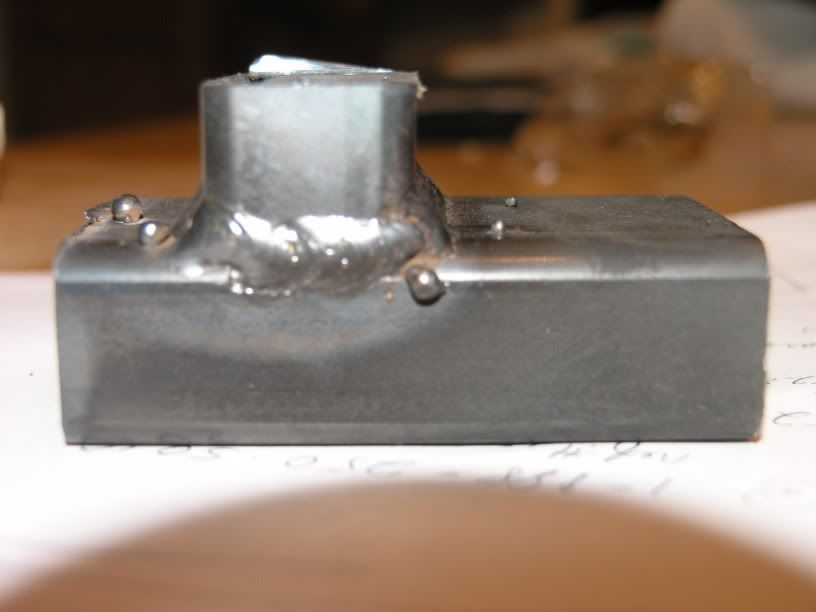

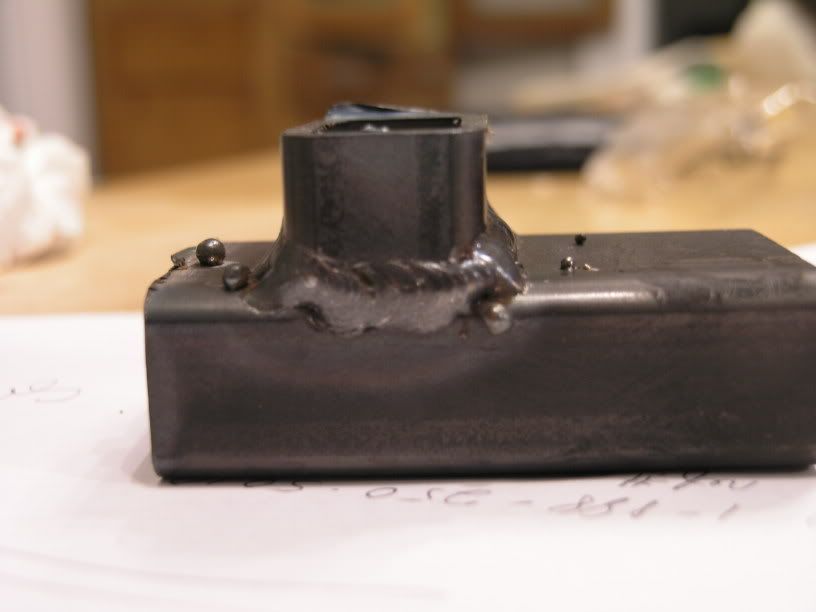

Now for the fun part. Weld from the center to the end, then from the beginning to the end so you end up with 2 welds and overlapping in the center. You need a long run so you can get a nice continuous run. (no vertical down or up, just a nice horozontal weld.)

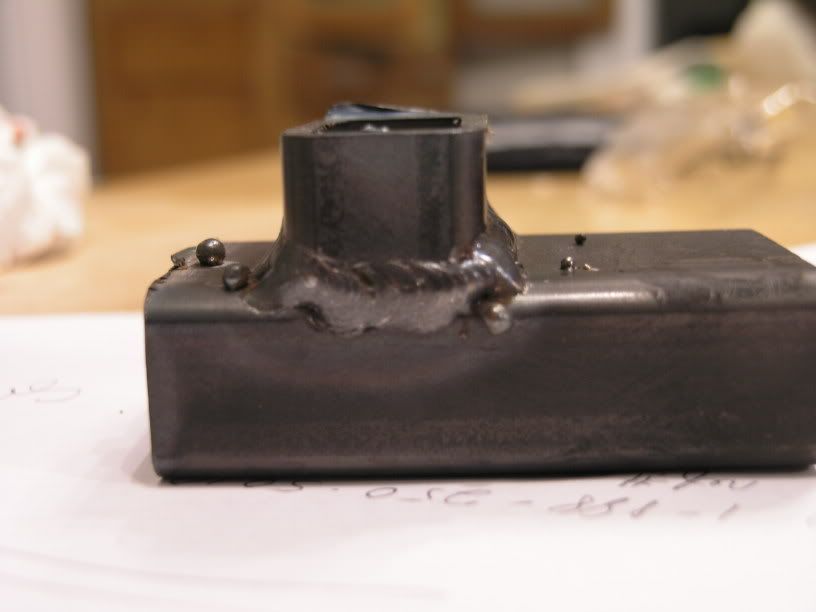

Let it cool and leave it alone.

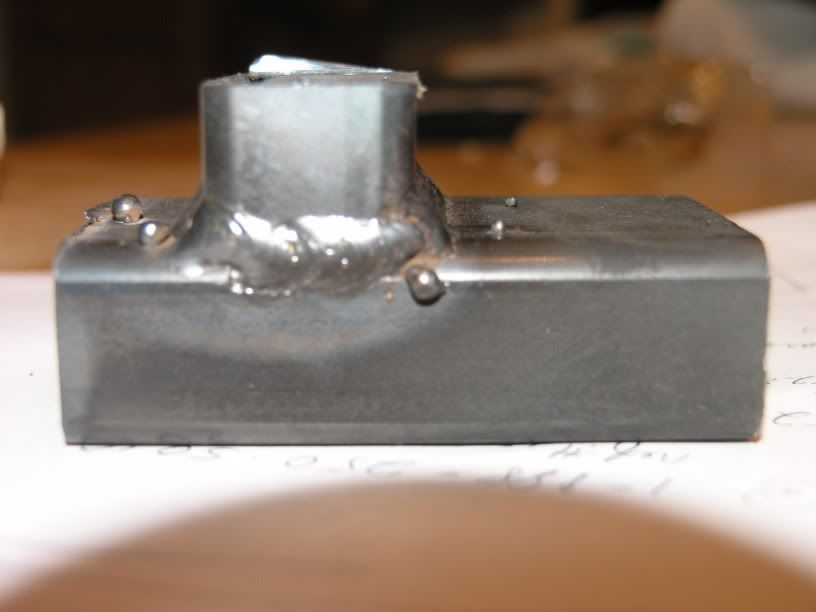

Once it has cooled cut a piece off as a cross section and look carefully and see if you have any holes right at the point where the 2 pieces meet. Wire brush it up and look for a contrast between the metals. (weld inspector will put some acids on the piece to highlight the different metals more clearly)

Cut another cross section cut and put it in a vice and try to break it appart. (use hammers, crush it in the jaws of the vise, anything to tear it appart) When it tears you will see where you got penetration and where you missed.

That is almost like a weld test I had to do for BHP so i can weld their frames for their mine sites. 6mm fillet weld to as1554-sp part1 (its a mickeymouse weld test but its amazing who still fails it)

ps a weld can look like shit on the outside and still pass due to the fact it has penetrated to the required depth. Some welds look beautiful on the outside then you tap it and it falls appart.

Make sure you nozzle is clean and your tips are free flowing along with a clean liner. Use a mixture of argon and other gas (pure argon as used in tig will leave the weld purple and co2 will leave it dull) but preperation is 90% of welding. clean all the crap off the parts needed to be welded and you should be fine.