Derek,

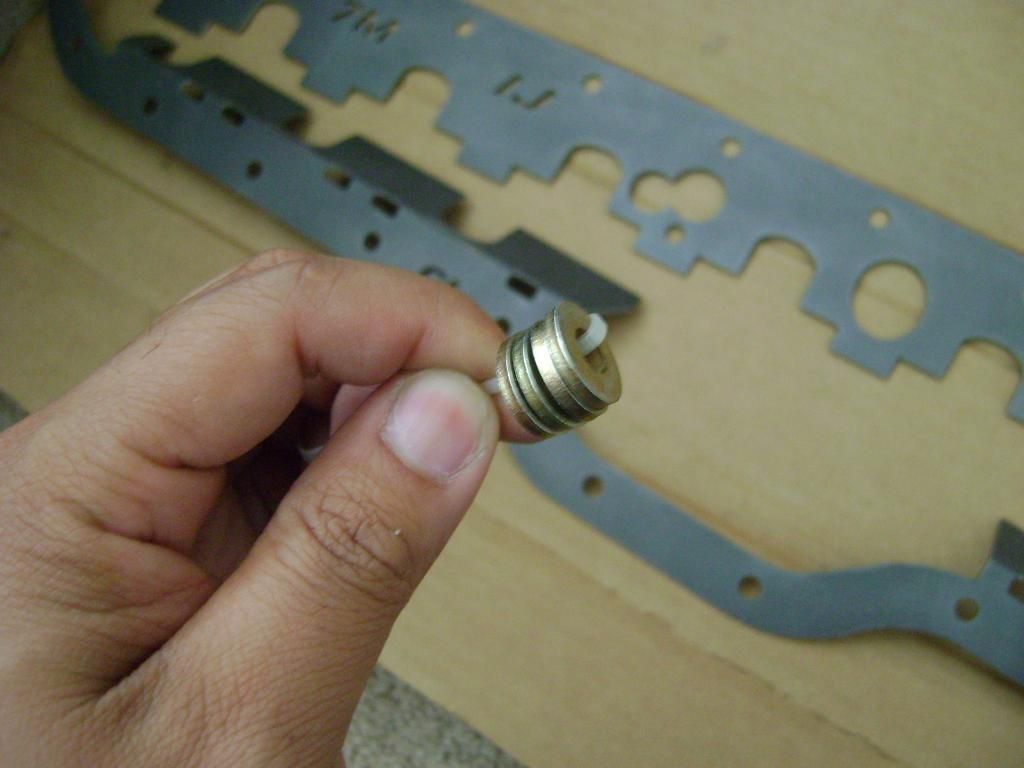

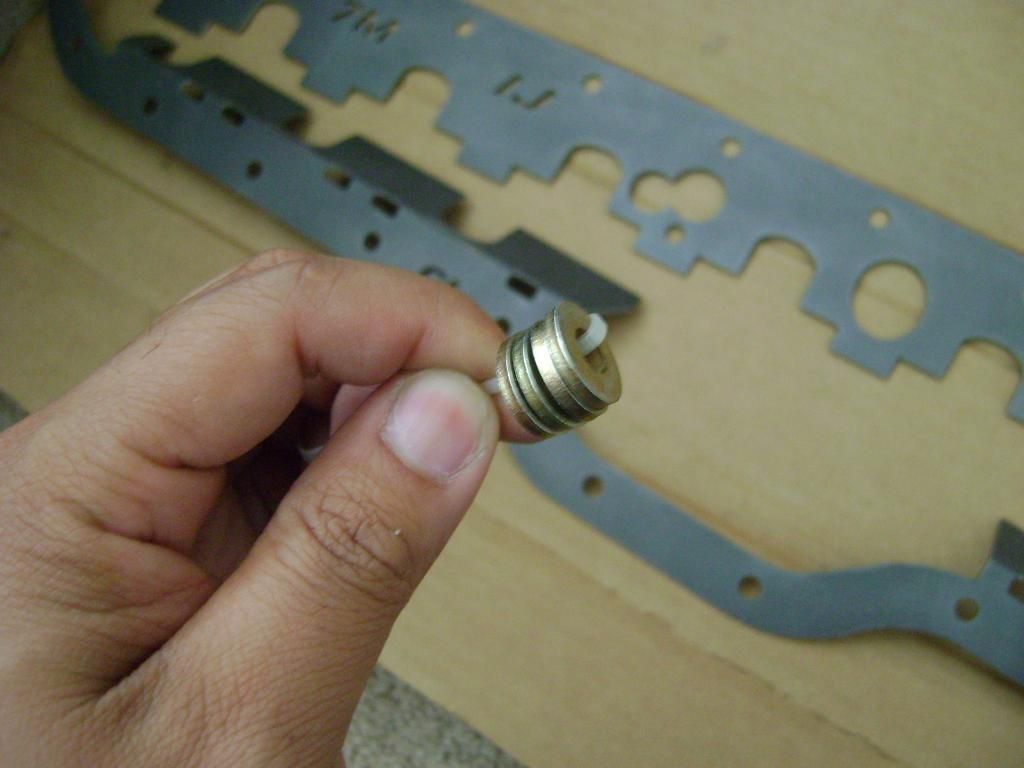

The fitting into the pump has a jamb nut and a special washer, to contain the o-ring. Therad all the way in, then back off as required to match the correct angle of our hardline.

On the engine block side, apply 2 revolutions of teflon tape to the tapered threads ONLY, thread gently into the block. That tapered thread has the power to split the block casting and customers have done it before. In this location it would be advisable to use the factory torque specs.

When torquing the B-nut on the hard line onto the fitting, it takes quite a bit of force, since you are sealing the 37deg surface between the line and the AN fitting. Its not a ton but a bit more than twice what it took to tighten the tapered fitting into the block. Obviously you will be using 2 wrenches, one on the fitting, (to keep it stationary) and one on the B-nut, to crush the soft metal hardline on to the 37deg surface.

You will know, they tighten very positively. DO NOT over tighten the tapered thread into the block. If the block is already split, don't panic, call me.