Yeah, shortly after posting this, i found that, looks like they're GTE cams, the lobes are perfectly within spec, towards the high end of spec, but the cam bearings aren't. 26.93mm, 26.75mm, 26.85mm, 26.89mm, 26.90mm, 26.82mm & 26.70mm from #7 to #1 - wtf?

1990 Toyota Supra Turbo Buildup - Satans Little Helper...

- Thread starter Kai

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

They were just a spare set i had laying around, the set i'm using is still in the head...

Here's how everything stands:

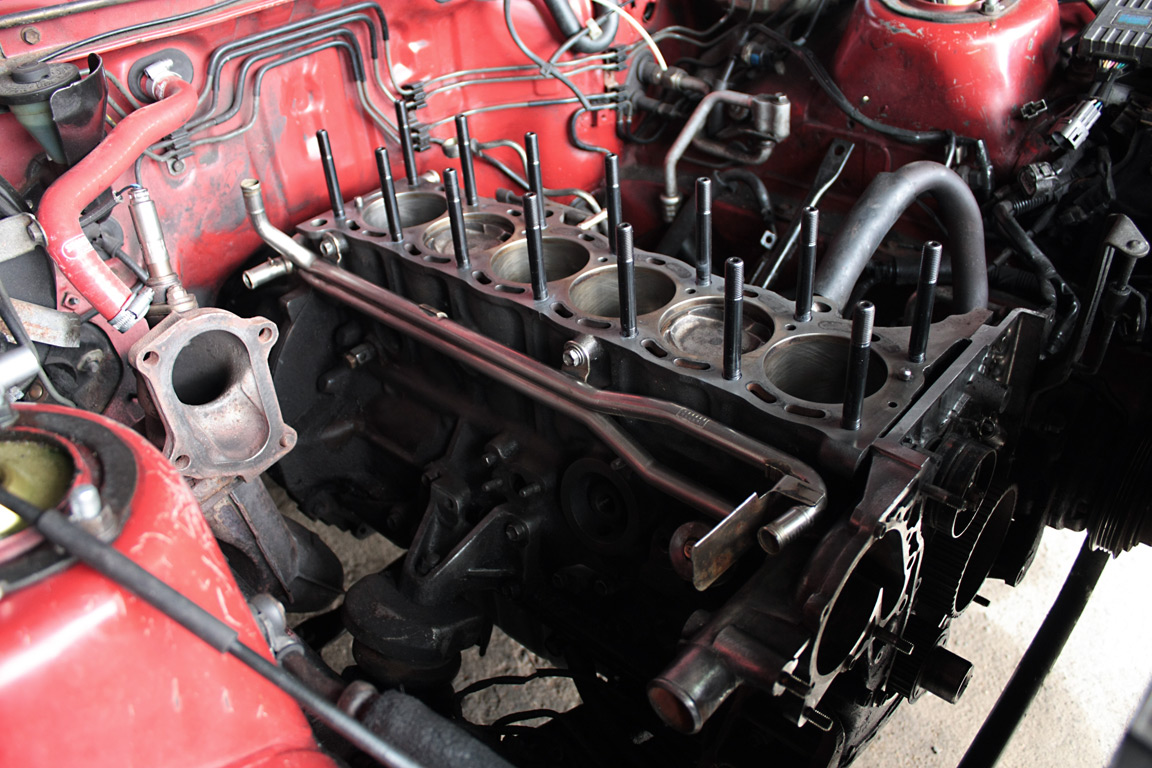

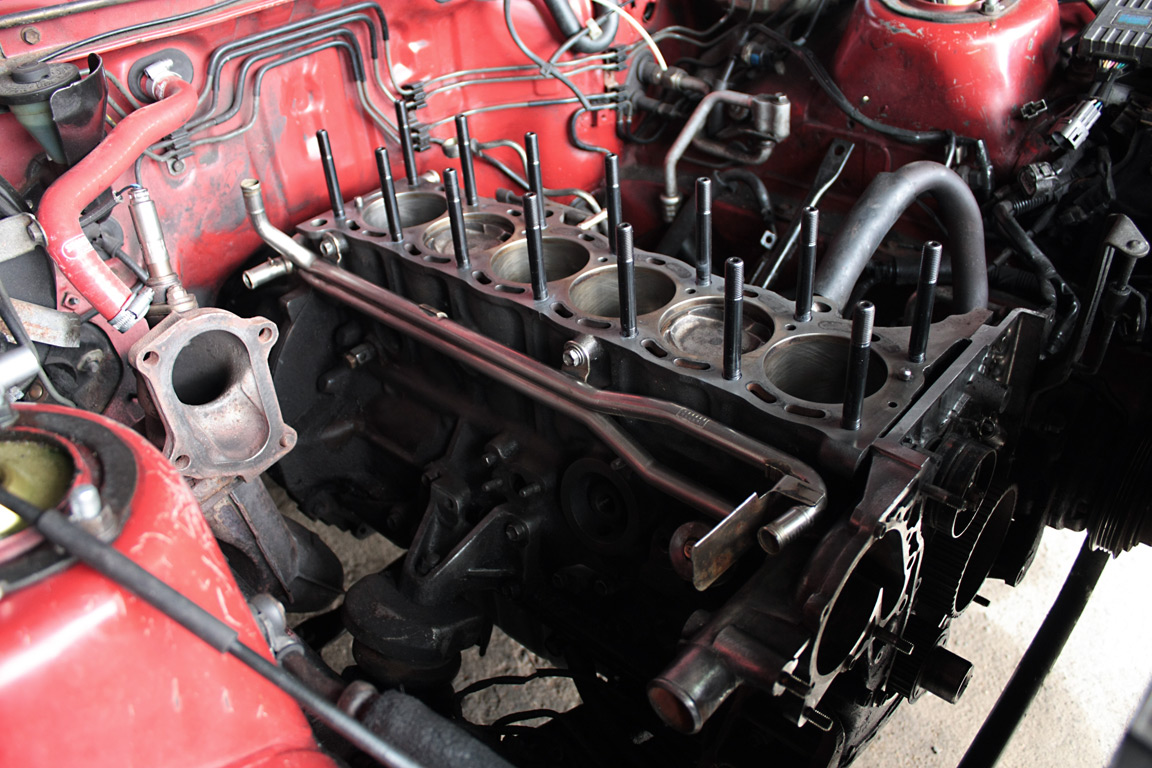

ARP studs installed (with the lube), new water pipe bolted on and gasketed up - ready for the head to go on! There was ONE snag though - the water pump housing uses two locating dowels, one at the top, one at the bottom (you can see them in the picture), and the bolts go through the middle of them. Sods law stepped in on my behalf - first bolt i decided to put in was the lower dowel bolt. Head sheared off as if the damn thing were made of cheese!

*cue lots of swearing, tools being flung into the courtyard, face turning red etc*

I thought - okay, as the bolt thread has just been tapped and the bolt ran through a die seconds before, it shouldn't be seized. The bolt just goes right the way through the housing, so i could feel it protruding. Tried unscrewing it from behind and it worked for about a turn, then i couldn't get enough torque on it. Again, cue swearing. I don't have any reverse drillbits or anything suitable to remove it. So, i considered leaving the bolt in there and just using some loctite sealant on the gasket around the dowel. But no, i ruled that out as being a bit cletus - and i'm a neat freak. Overengineered or not, i was determined to get this bastard thing out!

Phoned my mate ed, who explained that the dowels can be removed from the water pump housing (front timing plate) and you can buy spares. With the dowel out of the way, i'd have just enough protrusion to get a set of vice grips on the bolt and back it out that way. Time for a screwdriver and a hammer - sliced halfway through the dowel, and grabbed the lot with the vice grips - the dowel had mashed itself into the bolt thread still in there, and pulled it out when i turned the mangled dowel peg - WOOHOO! IT'S FREE & OUT!

Thankfully, and most unlike Toyota, the parts are still available (16185-70010, if you wanted to know ), and only €2.44 each + VAT @ 19.6% - i'll buy two, just in case, and use new bolts from the hardware store, cause i've had quite enough of shit breaking, it's why i've been anal about buying new studs for the exhaust side of things - you just KNOW they'll turn to cheese and shear!

), and only €2.44 each + VAT @ 19.6% - i'll buy two, just in case, and use new bolts from the hardware store, cause i've had quite enough of shit breaking, it's why i've been anal about buying new studs for the exhaust side of things - you just KNOW they'll turn to cheese and shear!

However i *STILL* need to get the damn shims...

Here's how everything stands:

ARP studs installed (with the lube), new water pipe bolted on and gasketed up - ready for the head to go on! There was ONE snag though - the water pump housing uses two locating dowels, one at the top, one at the bottom (you can see them in the picture), and the bolts go through the middle of them. Sods law stepped in on my behalf - first bolt i decided to put in was the lower dowel bolt. Head sheared off as if the damn thing were made of cheese!

*cue lots of swearing, tools being flung into the courtyard, face turning red etc*

I thought - okay, as the bolt thread has just been tapped and the bolt ran through a die seconds before, it shouldn't be seized. The bolt just goes right the way through the housing, so i could feel it protruding. Tried unscrewing it from behind and it worked for about a turn, then i couldn't get enough torque on it. Again, cue swearing. I don't have any reverse drillbits or anything suitable to remove it. So, i considered leaving the bolt in there and just using some loctite sealant on the gasket around the dowel. But no, i ruled that out as being a bit cletus - and i'm a neat freak. Overengineered or not, i was determined to get this bastard thing out!

Phoned my mate ed, who explained that the dowels can be removed from the water pump housing (front timing plate) and you can buy spares. With the dowel out of the way, i'd have just enough protrusion to get a set of vice grips on the bolt and back it out that way. Time for a screwdriver and a hammer - sliced halfway through the dowel, and grabbed the lot with the vice grips - the dowel had mashed itself into the bolt thread still in there, and pulled it out when i turned the mangled dowel peg - WOOHOO! IT'S FREE & OUT!

Thankfully, and most unlike Toyota, the parts are still available (16185-70010, if you wanted to know

However i *STILL* need to get the damn shims...

Well, today i managed to drum up enough energy to lift the head onto the block - it's not exactly heavy, it's just bulky & awkward when you're on your own. Turns out that if you try to install the ARP studs in the block when the block is in the car, the head will foul against the firewall, so, the studs all came back out again, gasket was put in place over the dowel pegs in the block and the head put on top.

ARP's then had the nuts installed (with plenty of moly lube) and the washers dropped into place. The one problem i have is...the 14mm 1/2" drive socket i have, the walls are too fecking thick to get into the head! DOH! So, i had to use the 9/16" 3/8ths socket i have on the 3/8ths Torque Wrench, and tightened the nuts to 30lb/ft as a first stage. In an hour or so, i'll tighten them to 40lb/ft (the limit of the torque wrench) and leave it to settle overnight. It's a sunday, so nothing is open, and i'll have to scout around for a place that'll sell an adapter tomorrow so i can use my 1/2" drive torque wrench that goes to 160lb/ft.

You may notice that the cams aren't in the head yet. Well, theres a reason for that - i was doing shims yesterday, and decided that it's little point putting the cams back on, and then taking them back off again when i get shims that fit! Yes, yes, i know you can do the shims with the cams in place - but really, i can't be dealing with the two person ball ache!

I'm still waiting on parts from the UK (most of them didn't arrive on tuesday, the ones from the dealership weren't in from Japan yet, and the harness was still being finished off) - no fear though, i have patience!

ARP's then had the nuts installed (with plenty of moly lube) and the washers dropped into place. The one problem i have is...the 14mm 1/2" drive socket i have, the walls are too fecking thick to get into the head! DOH! So, i had to use the 9/16" 3/8ths socket i have on the 3/8ths Torque Wrench, and tightened the nuts to 30lb/ft as a first stage. In an hour or so, i'll tighten them to 40lb/ft (the limit of the torque wrench) and leave it to settle overnight. It's a sunday, so nothing is open, and i'll have to scout around for a place that'll sell an adapter tomorrow so i can use my 1/2" drive torque wrench that goes to 160lb/ft.

You may notice that the cams aren't in the head yet. Well, theres a reason for that - i was doing shims yesterday, and decided that it's little point putting the cams back on, and then taking them back off again when i get shims that fit! Yes, yes, i know you can do the shims with the cams in place - but really, i can't be dealing with the two person ball ache!

I'm still waiting on parts from the UK (most of them didn't arrive on tuesday, the ones from the dealership weren't in from Japan yet, and the harness was still being finished off) - no fear though, i have patience!

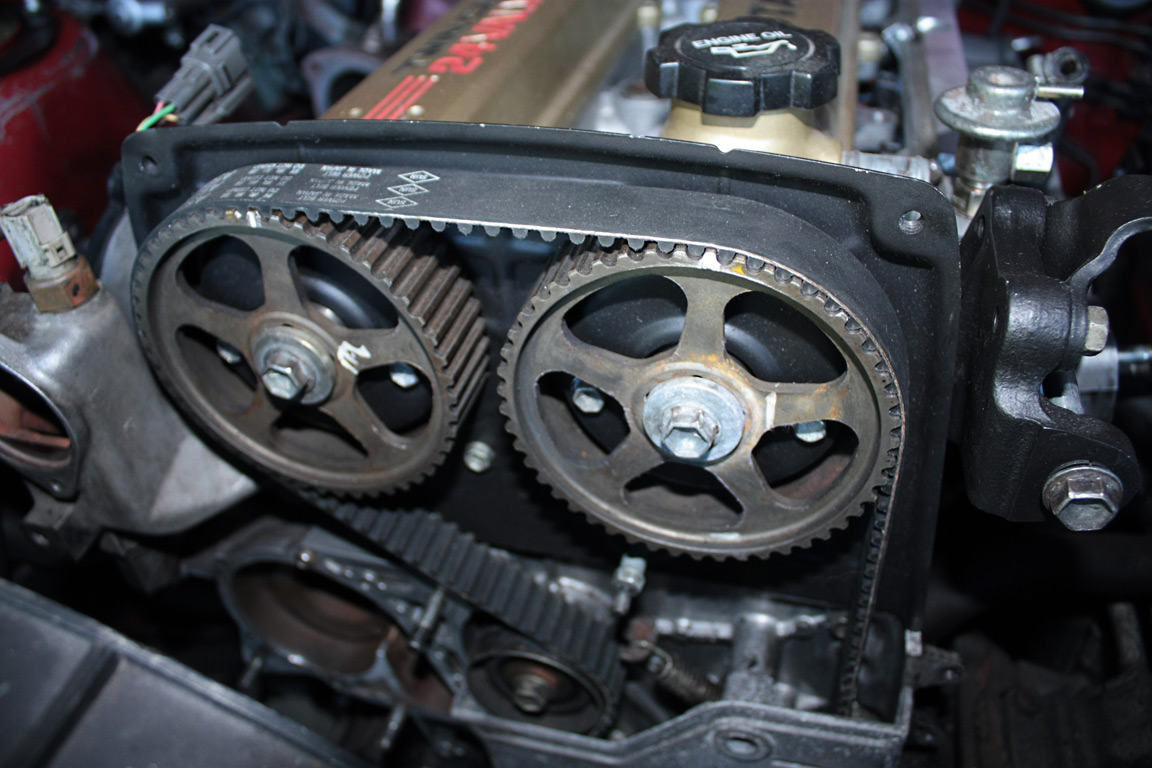

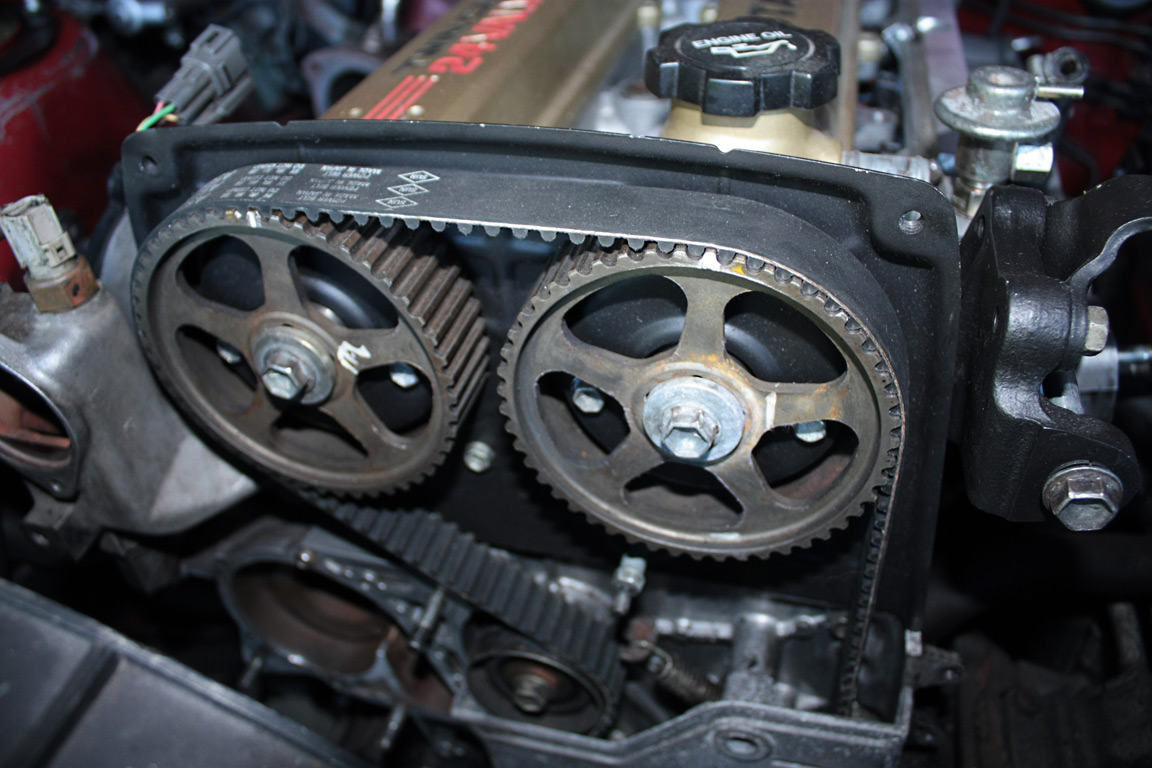

So i thought 'bugger it' and installed the cams - i measured the thickness of all of them before the cams went in and were bolted down, i'll just deal with the two person ball ache when the time comes - i just want to get as much of this back together as much as possible!

And of course, with the cam pulleys in, but not torqued up to 36lb/ft yet!

It's too dark to continue, even with the work light - and its grungy and 'orrible weather out there, so this really IS all i'm doing for the day!

Tomorrow i'll measure valve clearances again and knock up a final list of 'shims i need'.

And of course, with the cam pulleys in, but not torqued up to 36lb/ft yet!

It's too dark to continue, even with the work light - and its grungy and 'orrible weather out there, so this really IS all i'm doing for the day!

Tomorrow i'll measure valve clearances again and knock up a final list of 'shims i need'.

Right - i dropped the cam covers on today, just to get an idea of what this will eventually look like - i must say, it looks pretty good to me!

FINALLY! Yesterday in the mail, a parcel arrived from the UK - only a small jiffy bag, but containing the 1/2" to 3/8" adaptor that i desperately needed! All the nuts on the studs were torqued up in stages (30, 40, 50, 60, 70 lb) and finally 75lb/ft for the final pass. I was thinking about going to 80lb/ft *but* the socket i'm using runs the risk of shearing before the nuts do! So i'm going to call an end to head torquing proceedings. Oh, and i measured the valve clearances again.

*swearing*

I think this engine relies solely on the powers of voodoo sometimes - the clearances are marginally better than they were, but i have to get shims still. I can run the engine as is - but it will sound rattly and won't be as tuned as i like. But, the good thing is, i can do other stuff while i wait on those. I think i'm just going to have to bite the bullet and go to Toyota for them, i can't be bothered driving 120 miles round trip to go to a Yamaha dealer (the 7M uses 25mm diameter shims that can also be found in a load of bikes).

*swearing*

I think this engine relies solely on the powers of voodoo sometimes - the clearances are marginally better than they were, but i have to get shims still. I can run the engine as is - but it will sound rattly and won't be as tuned as i like. But, the good thing is, i can do other stuff while i wait on those. I think i'm just going to have to bite the bullet and go to Toyota for them, i can't be bothered driving 120 miles round trip to go to a Yamaha dealer (the 7M uses 25mm diameter shims that can also be found in a load of bikes).

...I HATE THE TIMING BELT ON THIS F*CKING ENGINE! >_<

Seriously - it's bad enough that i have to take off the crank pulley and the lower timing cover, but honestly...this thing is just RIDICULOUS!

Looks so easy in the TSRM - just move the belt tensioner pulley over, bolt it up hand tight so it gives the belt slack...then stretch the belt over, right? The amount of swearing and scraped knuckles it's taken to achieve the end result is simply unreal!

Still, it's on.

I'm running out of things to do - i can't do anything more until i have the wiring loom back at the very least - and i *need* those parts from the UK so very badly

The one thing i guess i CAN do, is bolt up the fuel rail, pulsation dampers and all that faff...

Seriously - it's bad enough that i have to take off the crank pulley and the lower timing cover, but honestly...this thing is just RIDICULOUS!

Looks so easy in the TSRM - just move the belt tensioner pulley over, bolt it up hand tight so it gives the belt slack...then stretch the belt over, right? The amount of swearing and scraped knuckles it's taken to achieve the end result is simply unreal!

Still, it's on.

I'm running out of things to do - i can't do anything more until i have the wiring loom back at the very least - and i *need* those parts from the UK so very badly

The one thing i guess i CAN do, is bolt up the fuel rail, pulsation dampers and all that faff...

Fuel rail has been put back together - i'm waiting on the wiring harness to arrive from the UK, exhaust studs and turbo elbow studs/nuts etc, some O-rings and gaskets (specifically for the PS pump) and i think i'm going to need some red vacuum hose & bungs, as the EGR has come off...

Not in the slightest - its been holding me up for weeks now...and even when i get it, i've got a lot of work to do. I found ANOTHER hole in the hell thats been plated/riveted - i need someone that can weld

Kai;1442591 said:Right - i've showered, dressed myself, and soaked up a beer or three. Breakfast of champions. Hooah.

Notice the rear bumper - hanging from...well....nothing! It's being held on by one bolt and a lot of faith!

That looks pretty good. A decent body condition is important.

Nick - if you'd read more, you'd have seen that the shell is somewhat...rusted. Inner and outer arches have been patched, i've found MORE holes as well...

Kai;1583974 said:Nick - if you'd read more, you'd have seen that the shell is somewhat...rusted. Inner and outer arches have been patched, i've found MORE holes as well...

I read it. It looks ok from the outside, and that is important.