MDCmotorsports;1566698 said:

Not much to add to your thought process other than this:

The Duramax VGT turbos have this "homing process" you speak of, every time you turn the key on, engine off. This keeps the veins of the VGT system clean and free from soot.

The Ford 6.0 VGT turbos DO NOT have this "homing process" you speak of, and subsequently they have a high report problem to the dealer of boost problems.

Yes that will be incorporated in this design...........

I have 90% of the parts I need to really get this controller going. First the controller will work directly off shaft RPM using the built in VR sensor. I will be using a Atmel ATMega644 40-pin 8-bit microcontroller so this will be a standalone controller. Along with a LCD redout to tell you turbo shaft speed, vane position, throttle position, and soon EGT. There will be a 9-pin RS-232 (serial) interface to change the paramaters etc. Then some safety features such as critical shaft speed warning, high EGT warning, and a feature to let you see the highest numbers reached.

I have a small stepper motor right now that will be used to prototype with but will be getting a stronger more expensive one to do the actual actuation of the vanes.

http://www.linengineering.com/LinE/ has a great line of stepper motors that should do the job well.

As I get more parts I will keep this thread updated as I figure more stuff out.

This is how it will work.

TPS = Throttle Position Sensor

TurSS= Turbo shaft speed

TarSS= Target shaft speed

EGT= Exhaust gas Temperature

So when TPS is below 20% the vanes will be wide open allowing for low EGT.

When TPS goes above 20% the vanes will close down which will increase TurSS.

Then as TurSS rises to TarSS and when TarSS is reached and TurSS keeps rising the vanes will be opened more to reduce

TurSS back down to TarSS.

Then if TPS drops back below 20% the controller will wait about 2 seconds before opening the vanes to 100%.

There should be a Hysteresis of about 5k to 15k rpm to prevent the stepper from over heating from stepping to fast and to prevent rapid changes.

Later on I'll add in EGT circuit as a safety to prevent burning holes from to high of EGTs for a safety.

Also the parts to do this should be no more then $150 once it is all said and done.

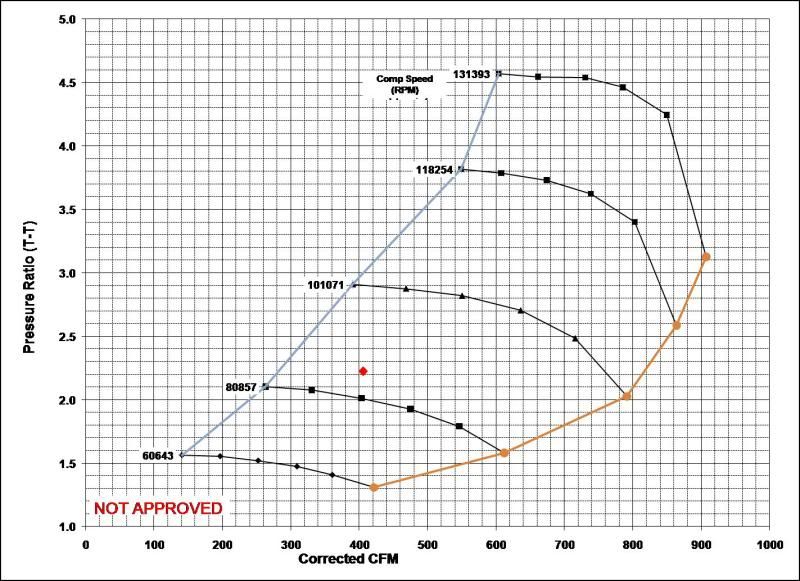

Alright MDCmotorports can you find me a compressor map for the HE351VE?