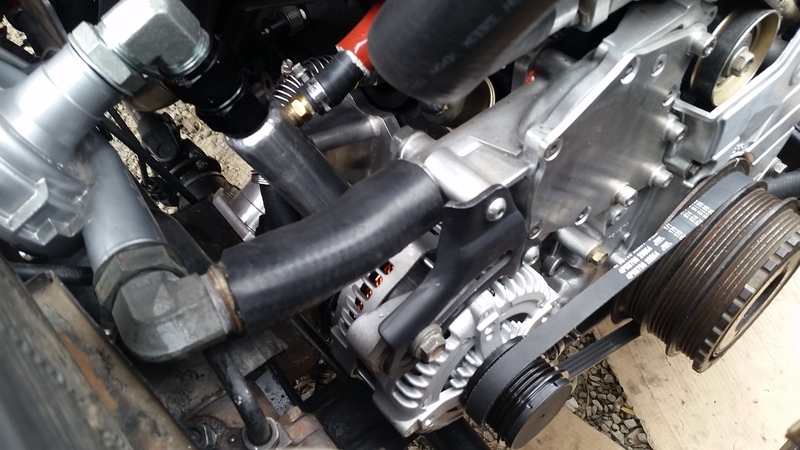

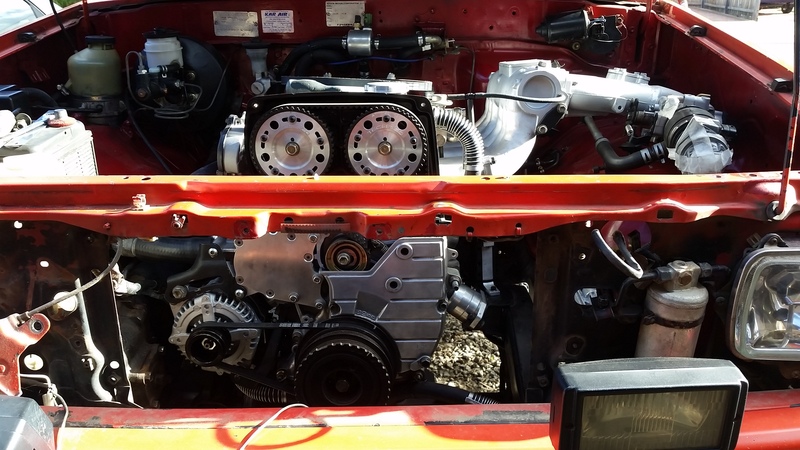

Thanks, some good info there and nice to know the 2j alternator fits without too much work. The mechman looks like a great piece of kit but more than I'm looking to spend unfortunately.

There are a million "high output" rewound 2jz alts on ebay in the 160-200 amp range but it seems there are mixed reviews on their performance. There's plenty of 7m options upto 150 amp as well, I wonder if the DM unit is just one of these?

I had thought about using a modern ford (or other brand) unit but I'm unsure how to wire them into the car as they all seem to have less connections on the back than the 3 (batt, ign, light) I'm used to on toyota alts.

There are a million "high output" rewound 2jz alts on ebay in the 160-200 amp range but it seems there are mixed reviews on their performance. There's plenty of 7m options upto 150 amp as well, I wonder if the DM unit is just one of these?

I had thought about using a modern ford (or other brand) unit but I'm unsure how to wire them into the car as they all seem to have less connections on the back than the 3 (batt, ign, light) I'm used to on toyota alts.

.jpg)