Hi there

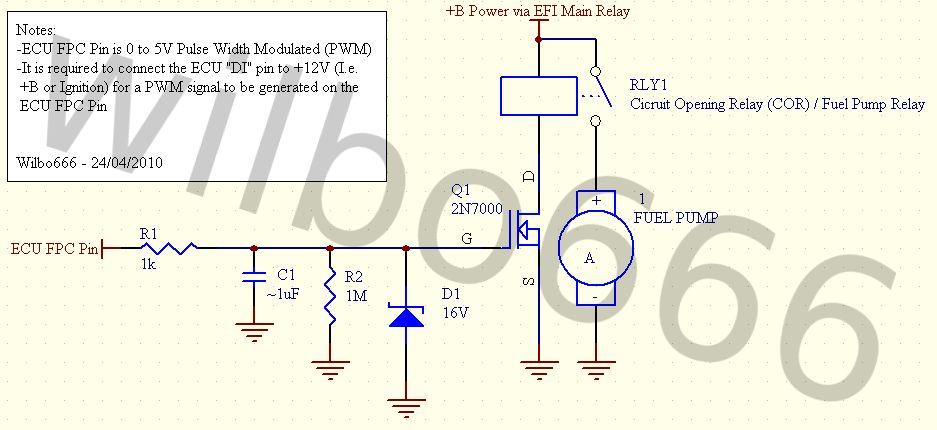

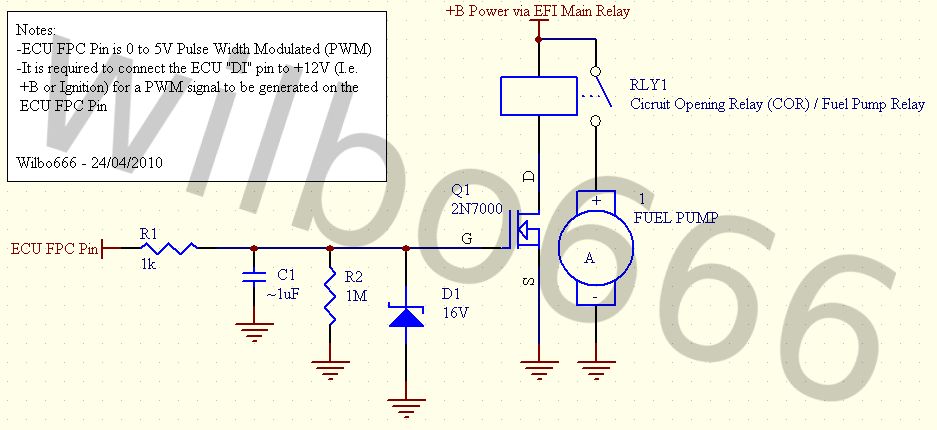

According to theese wiring-diagrams, the EFI relay is the main powersource for the JDM Soarer 1JZ-GTE fuel pump circiut, as its the only supplier for +12v to the fuel pump computer:

http://wilbo666.pbworks.com/w/file/fetch/51111357/xZZ3x%20Electrical%20Wiring%20Diagram%206737105%203-6.png

http://wilbo666.pbworks.com/w/file/fetch/51111360/xZZ3x%20Electrical%20Wiring%20Diagram%206737105%203-7.png

Pinout explanations:

http://wilbo666.pbworks.com/w/page/47216384/1JZ-GTE%20JZZ30%20Soarer#JZZ30ToyotaSoarer1JZGTEWiringDiagrams

With theese diagrams, I figured out that the terminals on the Fuel Computer are:

E: Earth for Computer (Same as Pump)

FP: 9 or 12v powersupply to pump (depending on FRC signal)

DI: Diagnostic input to the ECU, if the Fuel Computer is not healthy (Normaly 12v supplied from FC, if missing 12v FC is bad)

FRC: Puls Modulated signal from ECU, setting the 9 or 12v to the Fuel Pump.

B: Battery +12v supply.

I have shorted the B and the FP plug.... to make shure my external fuel pump relay is supplied with 12v instead of 9v, as the relay started to make strange clicking-noises (typical for 9v supply) at idle. But will the EFI main relay switch off in the event of a crash? (if the engine stops, etc)

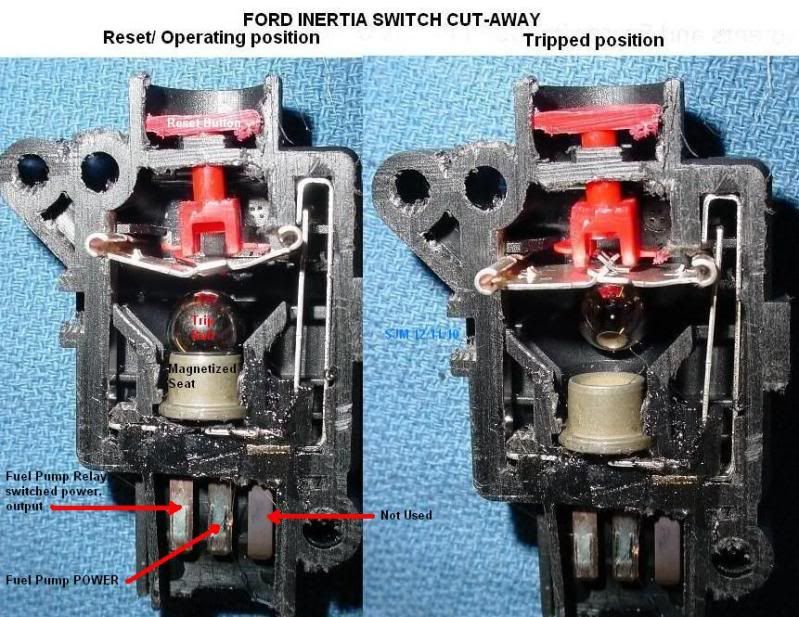

As far as I can see, the Main relay is controlled by the ECU itself, and the ECU must have some sort of safety-function with this relay? What else will stop the Fuelpump in the event of a crash.... the Pulse Modulated signal?

Just need some information, as this is a race-car and they crash alot

Thanx

According to theese wiring-diagrams, the EFI relay is the main powersource for the JDM Soarer 1JZ-GTE fuel pump circiut, as its the only supplier for +12v to the fuel pump computer:

http://wilbo666.pbworks.com/w/file/fetch/51111357/xZZ3x%20Electrical%20Wiring%20Diagram%206737105%203-6.png

http://wilbo666.pbworks.com/w/file/fetch/51111360/xZZ3x%20Electrical%20Wiring%20Diagram%206737105%203-7.png

Pinout explanations:

http://wilbo666.pbworks.com/w/page/47216384/1JZ-GTE%20JZZ30%20Soarer#JZZ30ToyotaSoarer1JZGTEWiringDiagrams

With theese diagrams, I figured out that the terminals on the Fuel Computer are:

E: Earth for Computer (Same as Pump)

FP: 9 or 12v powersupply to pump (depending on FRC signal)

DI: Diagnostic input to the ECU, if the Fuel Computer is not healthy (Normaly 12v supplied from FC, if missing 12v FC is bad)

FRC: Puls Modulated signal from ECU, setting the 9 or 12v to the Fuel Pump.

B: Battery +12v supply.

I have shorted the B and the FP plug.... to make shure my external fuel pump relay is supplied with 12v instead of 9v, as the relay started to make strange clicking-noises (typical for 9v supply) at idle. But will the EFI main relay switch off in the event of a crash? (if the engine stops, etc)

As far as I can see, the Main relay is controlled by the ECU itself, and the ECU must have some sort of safety-function with this relay? What else will stop the Fuelpump in the event of a crash.... the Pulse Modulated signal?

Just need some information, as this is a race-car and they crash alot

Thanx