Update:

I bought some shims from a local seller, but he only has a few thicknesses. 1.7mm, 1.73mm , 2.3mm and 2.36mm.

I decide to try 2.3mm(0.09") first. It is 0.33mm(0.013") over the original shim of 1.97mm(0.078")

with the pinion so deep, i had to use a thinnest carrier shim i have to get proper backlash.

Drive side went very deep:

Coast side seem to make no difference :

So I got my machinist to cut down the 2.36mm (0.093") shim to 2.1mm(0.082"), which is 0.13mm (0.005")over the original shim, I know you suggested 0.05mm(0.002") only, but I dont have those shims yet. I ordered special 45x35x0.1mm shims and they are only coming next week. with a 1.73mm shim plus 3 x 0.1mm shim I can get a 2.03mm which is 0.002" over the original shim as you suggested.

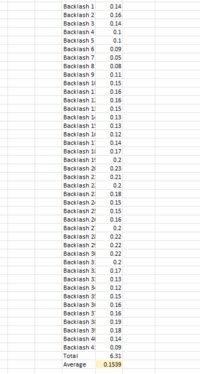

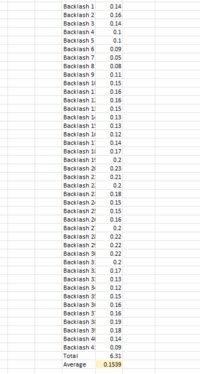

First I measured backlash of every single tooth, I made sure the ring gear runout is within spec, and it is only 0.03mm max.

But my backlash is all over the place. The loosest backlash is 0.22mm (0.0086") and tightest 0.05mm (0.002"), the average over 41 tooth is 0.15mm (0.006")

This variation is caused by either the pinion or ring gear profile.

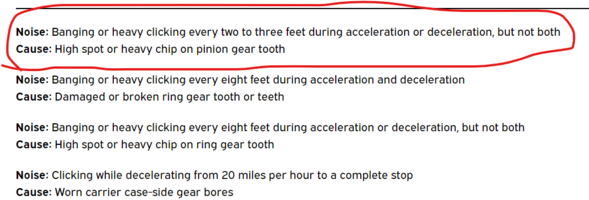

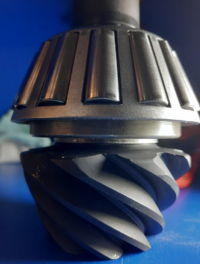

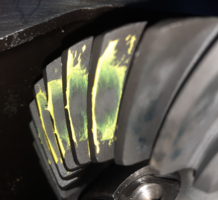

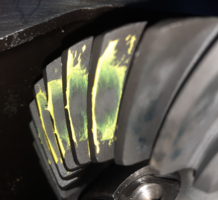

Seeing that there is nothing much that I can do about it, i proceed to get the gear pattern, this time I used yellow water color paint for much clearer pattern. Pinion head shim is 2.1mm(0.082"),

Drive depth seems ok, pattern more to toe

Drive

Drive :

Drive leftover paint :

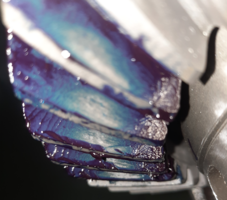

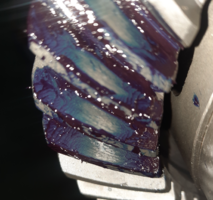

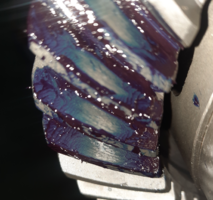

Coast seems ok, pattern centered between heel and toe

Coast leftover paint :

Coast leftover paint :

Coast

I dont think I can do any better than this. If I go deeper, the drive side will go deeper but coast remains the same, plus the deeper I go, the thinner the gear side carrier shim I will need, and I am already at the thinnest end of toyota's parts bin carrier shims.

If I go shallower, the coast side might be too shallow. The only next step I can go is 2.03mm(0.008") vs the 2.1 (0.083")

At 2.1mm pinion shim, the left carrier shim is now 2.61mm, the lowest toyota has is 2.58mm. If I go for 2.03mm pinion shim, I could probably use a 2.64 or 2.67mm carrier shim on the gear side, which I have with me.

Shall I run it as per yellow marked gear pattern ?