Alright folks, I'm beginning the removal of the head and I'll try to document it and provide somewhat of a how-to for the 7MGE. I'm a rookie when it comes to head removal, so please, ANY TIPS are greatly appreciated.

If any of you experts/veterans notice any potential or current flaws please let me know. I'm on a budget, but I want to do this right.

Things for preparation:

-disconnect negative lead from battery.

-prepare MANY ziploc bags. You're a damn fool if you think you can remember where all these bolts will go.

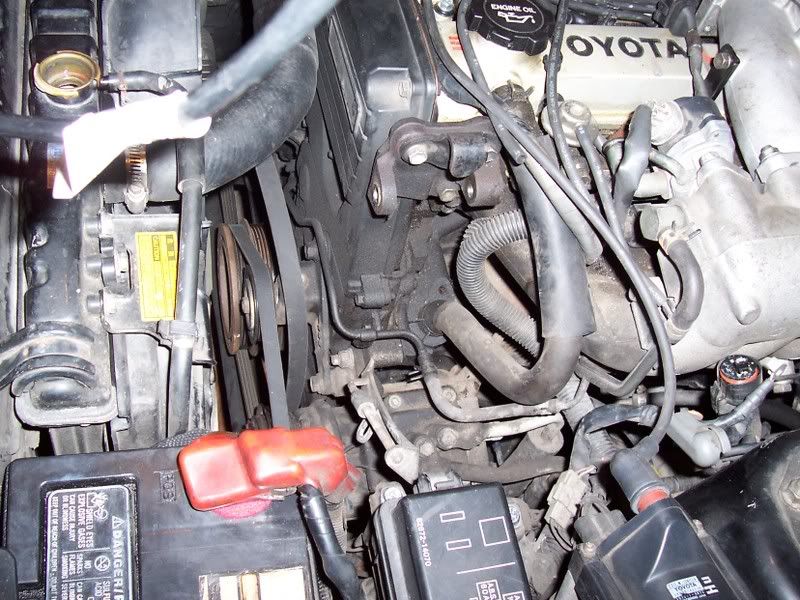

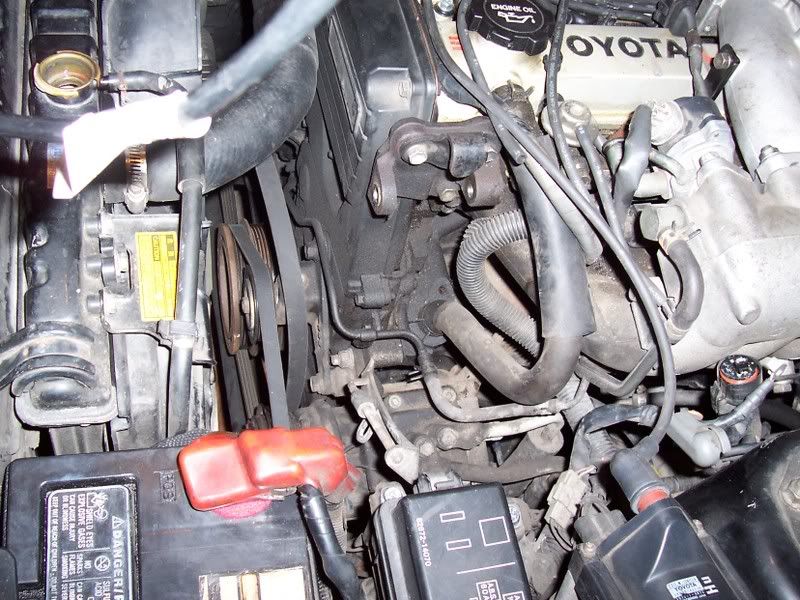

Pics of my progress:

Starting product:

Gloves are VERY crucial when working in Colorado in January in a poorly insulated garage. It's 10F outside.

I started by removing the accordion. When pulling this off remember the connector and the vacuum line.

Intake accordion off, here's what the rest of the intake looks like, durrr. Notice the high quality black duct tape.

I decided to move to the exhaust now. Gotta get the shield off which requires an awkward removal of the O2 sensor. California Spec dipsticks are in the way for this. I think non-cali cars will have easier access.

I now jacked up the car and drained the coolant from the radiator. The drain bolt at the exhaust manifold will be removed and drained after the exhaust is all out of the way.

Alternator removed. I hadn't ever done this before, but follow the TSRM and you should figure it out. Watch for the nut on the long threaded stud that allows tightening of the belt. I didn't find this right away.

Now I removed the throttle body. All the hoses simply pull off, but may very well need some persuading from a small flathead screwdriver.

A quick check in the oil cap just to be sure I got to this before something catastrophic happened... looks good!! No milkshake!!

Removed the y-intake pipe. The rear lower bolt is a bitch to get to, but if you remove the bracket it can be done with a wobbler extension.

Look at how dirty your intake can get! O_O Some carb cleaner and/or throttle body cleaner will be put to work on this later.

Next Morning:

Exhaust is off and now the coolant must be drained from the block. The bolt is on the backside and mine was VERY, VERY hard to break loose. There is a lot more coolant in the block and head than i thought there would be. Be ready.

Distributor needs to come off now. Follow the tsrm, but basically you need the motor @ TDC before you pull the distributor out. Turn the crank by hand and be sure the car is in neutral. Otherwise you'll be like me and trying to power your car with your arm. I call it 1 Andy-power.

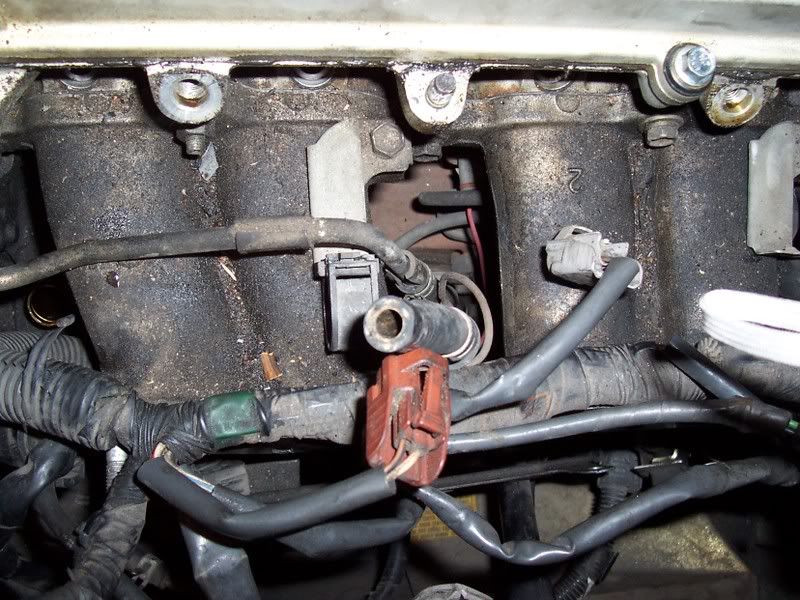

The mess on the intake side...

Plenum removed. There are plenty of connectors and hidden bolts to get you stuck here. I can't offer much more advice than to look at the TSRM diagrams for the cylinder head and try to find all the bolt holes.

If any of you experts/veterans notice any potential or current flaws please let me know. I'm on a budget, but I want to do this right.

Things for preparation:

-disconnect negative lead from battery.

-prepare MANY ziploc bags. You're a damn fool if you think you can remember where all these bolts will go.

Pics of my progress:

Starting product:

Gloves are VERY crucial when working in Colorado in January in a poorly insulated garage. It's 10F outside.

I started by removing the accordion. When pulling this off remember the connector and the vacuum line.

Intake accordion off, here's what the rest of the intake looks like, durrr. Notice the high quality black duct tape.

I decided to move to the exhaust now. Gotta get the shield off which requires an awkward removal of the O2 sensor. California Spec dipsticks are in the way for this. I think non-cali cars will have easier access.

I now jacked up the car and drained the coolant from the radiator. The drain bolt at the exhaust manifold will be removed and drained after the exhaust is all out of the way.

Alternator removed. I hadn't ever done this before, but follow the TSRM and you should figure it out. Watch for the nut on the long threaded stud that allows tightening of the belt. I didn't find this right away.

Now I removed the throttle body. All the hoses simply pull off, but may very well need some persuading from a small flathead screwdriver.

A quick check in the oil cap just to be sure I got to this before something catastrophic happened... looks good!! No milkshake!!

Removed the y-intake pipe. The rear lower bolt is a bitch to get to, but if you remove the bracket it can be done with a wobbler extension.

Look at how dirty your intake can get! O_O Some carb cleaner and/or throttle body cleaner will be put to work on this later.

Next Morning:

Exhaust is off and now the coolant must be drained from the block. The bolt is on the backside and mine was VERY, VERY hard to break loose. There is a lot more coolant in the block and head than i thought there would be. Be ready.

Distributor needs to come off now. Follow the tsrm, but basically you need the motor @ TDC before you pull the distributor out. Turn the crank by hand and be sure the car is in neutral. Otherwise you'll be like me and trying to power your car with your arm. I call it 1 Andy-power.

The mess on the intake side...

Plenum removed. There are plenty of connectors and hidden bolts to get you stuck here. I can't offer much more advice than to look at the TSRM diagrams for the cylinder head and try to find all the bolt holes.

Last edited: