My *sort of* build thread. (PIC WHORE)

- Thread starter CyFi6

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CyFi6;1248050 said:HAHAHA, oh my gosh, you guys are going to laugh. As if this engine couldnt get worse, i cleaned the pistons and whats stamped on them? .75..... Thats right, my pistons are a .75 oversize... that means my block is junk too. I didn't know how one engine can be so fucked up.... And worst of all i ended up with it, but i also payed out the ass for it. I cant believe this engine actually ran.

is that in mm? .75mm?

Yes, .75mm over i believe. If you take a look here in the tsrm it lists the "O/S .50"

http://www.cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=EM&P=78

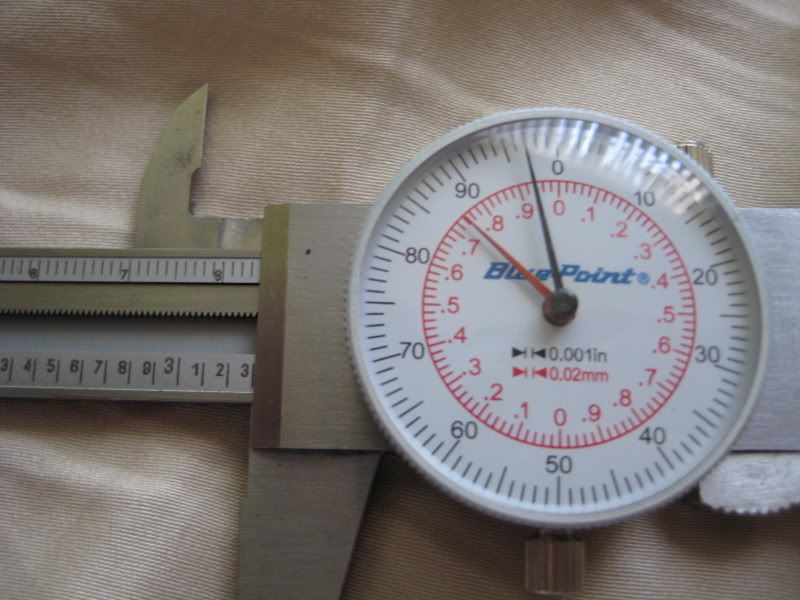

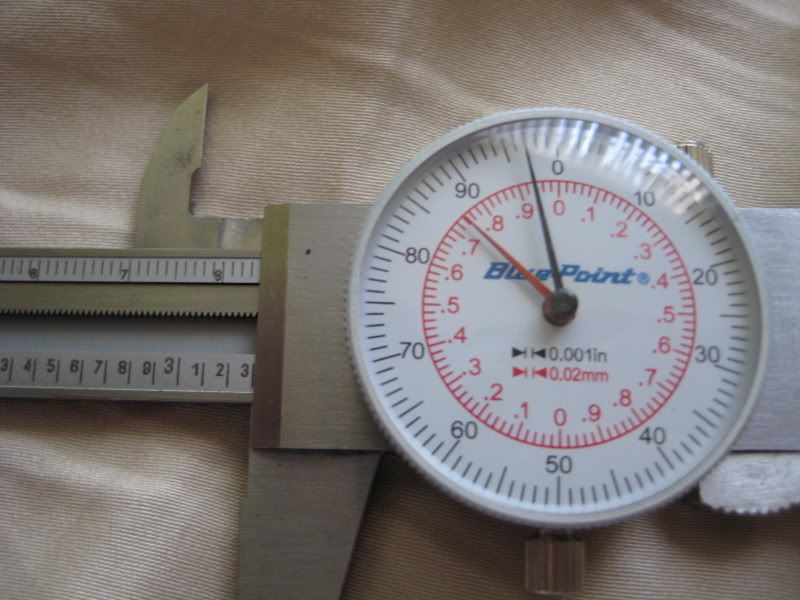

I dont have a mic big enough for the piston, but using a dial caliper for a rough measurement it was larger than the .50 o/s.

And you know i never fail on the pics

About ~3.297"... which is larger than the listed .50 oversize.

http://www.cygnusx1.net/Supra/Library/TSRM/MK3/manual.aspx?S=EM&P=78

I dont have a mic big enough for the piston, but using a dial caliper for a rough measurement it was larger than the .50 o/s.

And you know i never fail on the pics

About ~3.297"... which is larger than the listed .50 oversize.

do they make 1mm oversize? Is it even safe to run like that with the cylinder walls being so thin between cylinders? How big do they get? Thats like .040" over.

Does toyota make 1mm oversize or do i have to go aftermarket for those? Any idea how expensive they are?

OK well this is sort of back on track! I picked up a new bottom end recently for about 150 bucks. 89+ reinforced block, hot tanked, cleaned, stock bore stock deck height. Unfortunately the crankshaft from this one is fubar as well because someone let it run with the crank pulley loose and not only did it mess up the keyway, but the snout is about 15 thousands smaller where the crank pulley rides...:aigo:

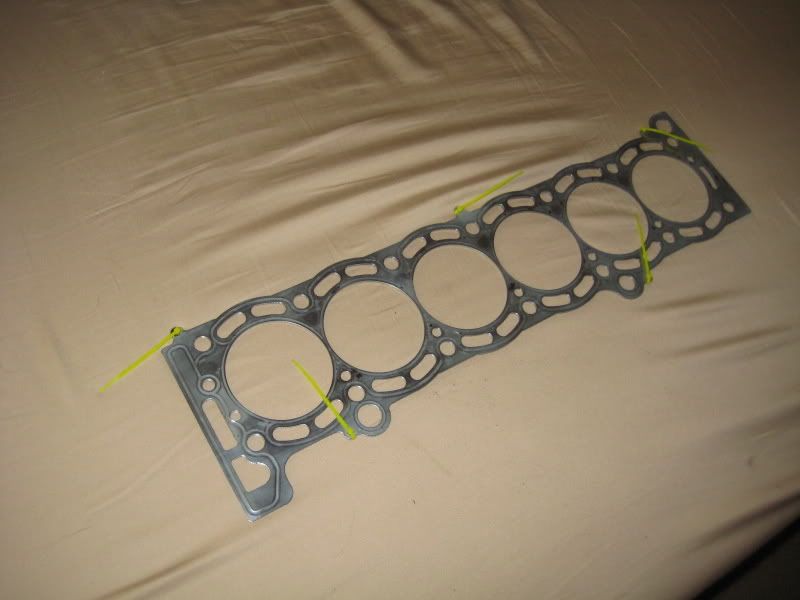

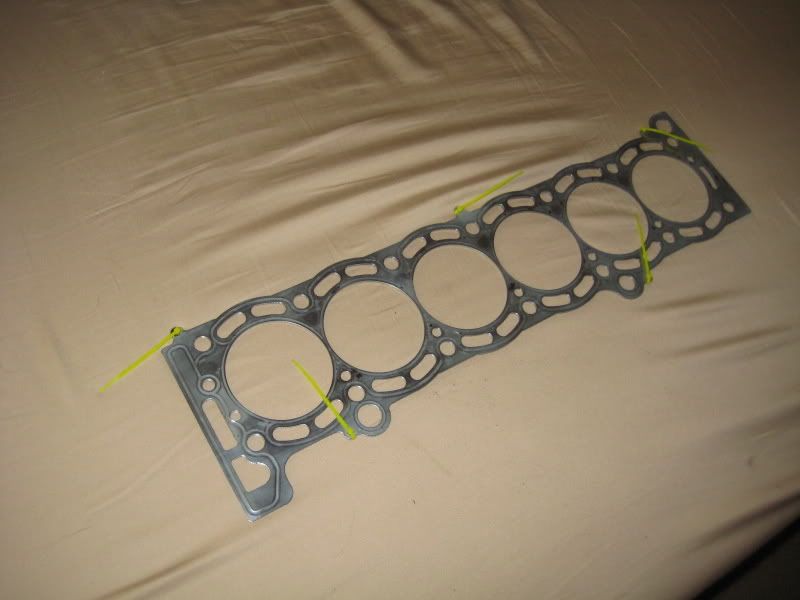

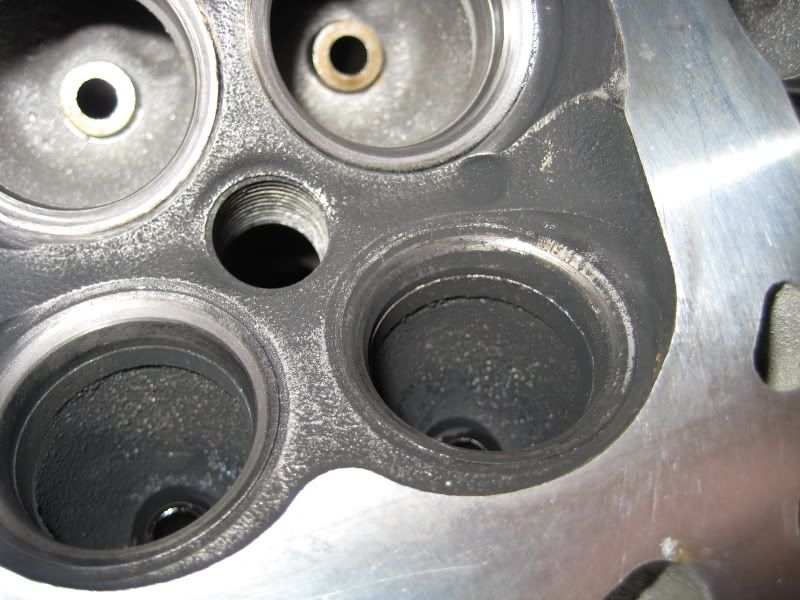

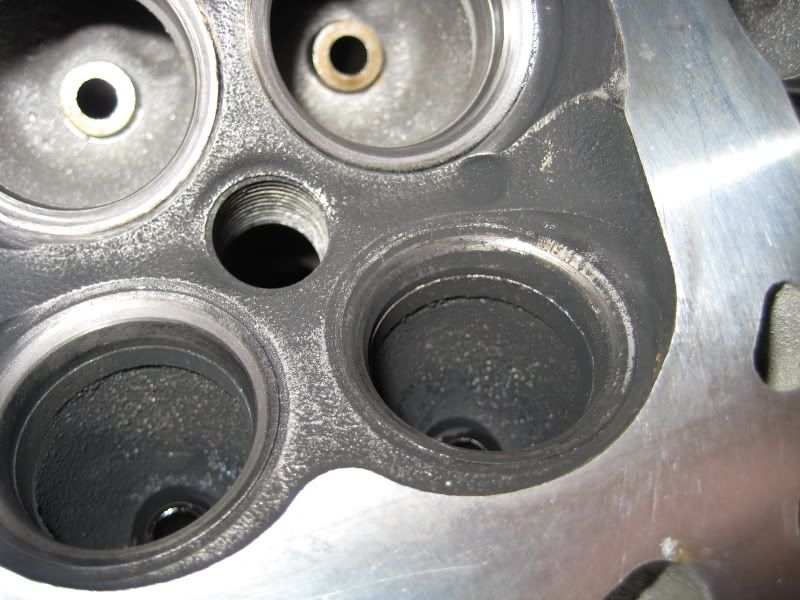

Anyways, I was originally planning for a simple hone and re- ring but i found a score in the number one cylinder that may be too deep, so i might be looking at going .020" over. Heres a picture of the block. I need some help on identifying this head gaskett hough. What brand is it? I measured it to be 1.2mm and want to sell it (spent hours cleaning it.)

Thanks! Wish me luck!

So far what i need/need to do

- Need new crank

- Toyota matched bearings

- .020" pistons

- Rings

- Machine work ( Check for cracks, bore, hone, deck head and block for MHG)

Thats the majority of it, but that is looking like a lot of money right now so it will be a slow process. I have most all of the gaskets and seals i need as well as all random bits and pieces.

Anyways, I was originally planning for a simple hone and re- ring but i found a score in the number one cylinder that may be too deep, so i might be looking at going .020" over. Heres a picture of the block. I need some help on identifying this head gaskett hough. What brand is it? I measured it to be 1.2mm and want to sell it (spent hours cleaning it.)

Thanks! Wish me luck!

So far what i need/need to do

- Need new crank

- Toyota matched bearings

- .020" pistons

- Rings

- Machine work ( Check for cracks, bore, hone, deck head and block for MHG)

Thats the majority of it, but that is looking like a lot of money right now so it will be a slow process. I have most all of the gaskets and seals i need as well as all random bits and pieces.

UPDATE! I picked up a running shortblock and im going to toss it together and use that. Im going to do a hone/re-ring and replace the bearings, even though they looked good. They are Toyota select fit bearings, phew. No guesswork involved. Did some work on the head recently.

Work included:

-Disassemble completely

-Re-clearance cam journals

-Pressure wash

- Hand lap valves, check guide clearance

- New valve seals

- Assemble valve train

- Adjust valve lash

Did the majority of it today. I was able to make my own little tool to install the valve retainers and keepers. All i did was use a 15mm socket+extension with a small piece of rubber hose in the center. Assemble all the valve pieces, place keepers into retainer on top of spring, make sure a rag is holding the valves closed, put this little doohickey on top and give it a quick compression. The socket pushes the retainers down and the rubber hose pushes the keepers into place. I recommend everyone use this method instead of going out and buying expensive tools .This method worked on every valve the first try.

Some pics

Work included:

-Disassemble completely

-Re-clearance cam journals

-Pressure wash

- Hand lap valves, check guide clearance

- New valve seals

- Assemble valve train

- Adjust valve lash

Did the majority of it today. I was able to make my own little tool to install the valve retainers and keepers. All i did was use a 15mm socket+extension with a small piece of rubber hose in the center. Assemble all the valve pieces, place keepers into retainer on top of spring, make sure a rag is holding the valves closed, put this little doohickey on top and give it a quick compression. The socket pushes the retainers down and the rubber hose pushes the keepers into place. I recommend everyone use this method instead of going out and buying expensive tools .This method worked on every valve the first try.

Some pics

Lookin good man! Keep up the work, cant wait to hear that turbo under the hood.CyFi6;1311087 said:Head is complete!

ok NOW its all done:icon_bigg Driftmotion studs/helicoils in. Just a tip for anyone else, get the damn machine shop to do it, this thing was a pita.:3d_frown:

My closet...3 7m's later

My closet...3 7m's later

looks nice, i never did get around to rebuilding my head, but you make it look easy.

oh and any chance 1 of those cranks are still good? i need one and dont wanna send mine out to get reground...

oh and any chance 1 of those cranks are still good? i need one and dont wanna send mine out to get reground...

OUCH!!! Good thing those 2 cranks are out and done. Could have been someone's nightmare.

Keep up the good work! I just finished my swap and complete running perfectly.

Keep up the good work! I just finished my swap and complete running perfectly.