Mod list:

Built Block-

-Eagle Rods

-Arias pistons, .020 overbore (84mm, 83.5 is oem)

-ARZ upgraded oil pump crossover tube

-5mm shimmed oil pump pressure relief

-5mm shimmed oil pump pick up

-ACL bearings, STD size

-Block decked about .020" for 2mm HKS Stopper

-ARP Head Studs torqued to 85 ft/lbs

-ARP Series 2000 3/8" (7/16" 12-point head) connecting Rod Bolts, 43 ft/lbs

-Main and Rod bearings set to .030

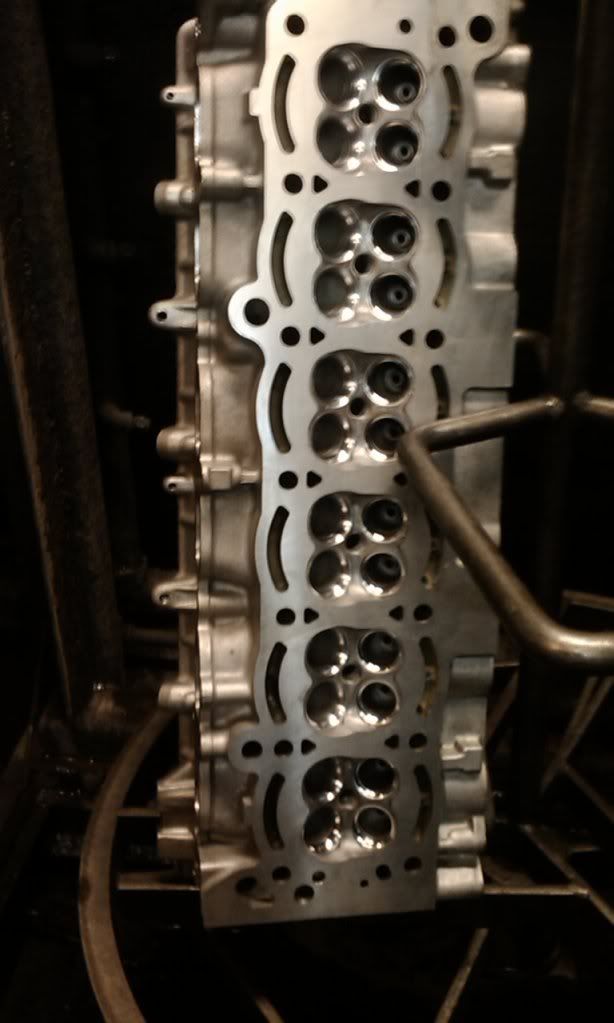

Built Head-

-Supertech Oversize valves, .5mm Intake and Exhaust

-BC Springs and Retainers

-BC 272 Cams

-mild porting, gasket matched intake

-Toyota valve stems and valve seals, cam seals

-Ferrera adjustable cam gears

-Gates performance timing belt (blue)

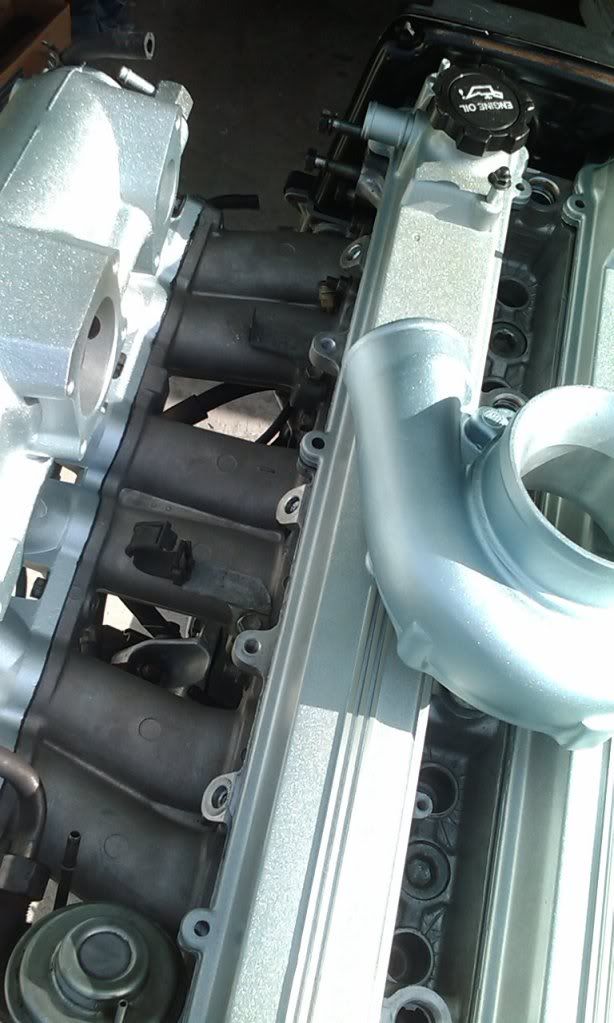

Turbo- Bolt-on T70

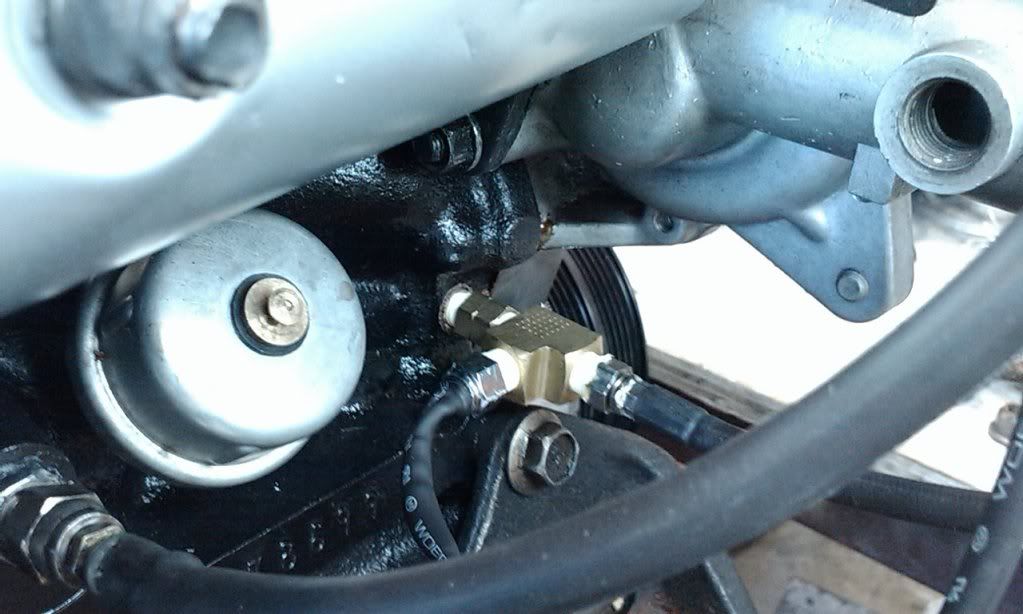

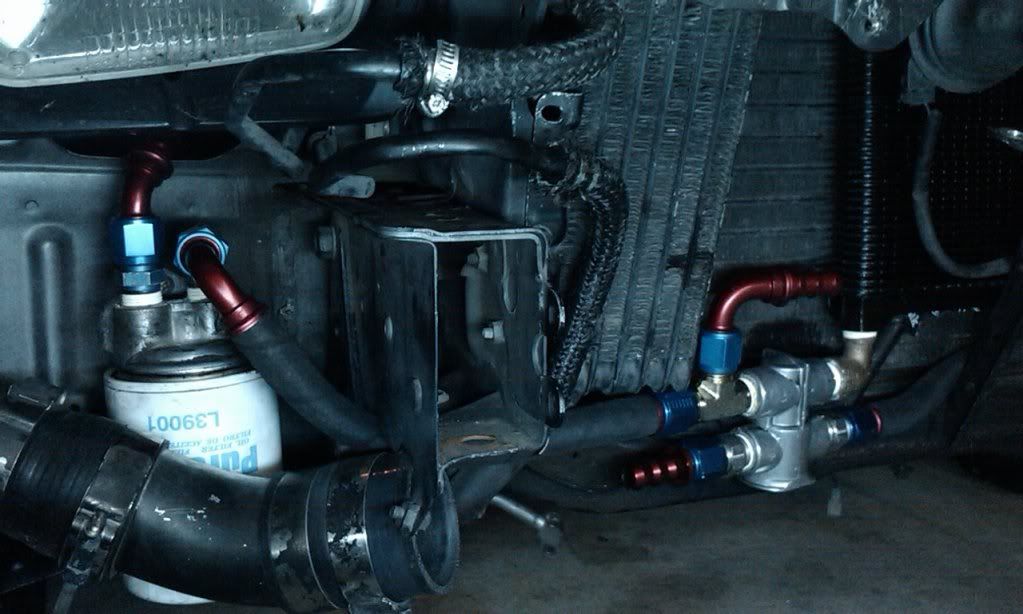

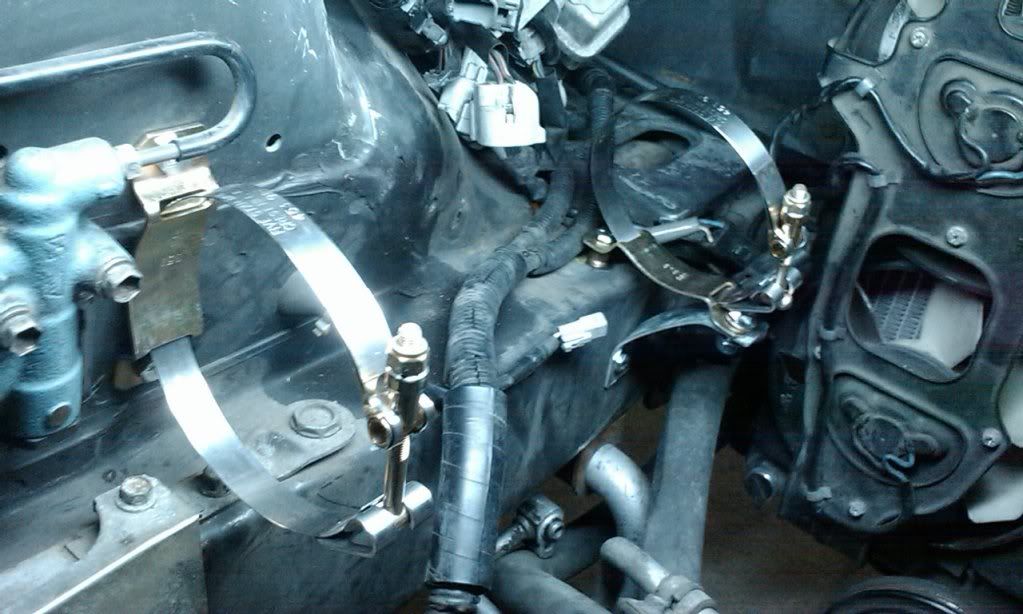

AN-10 oil system with 8x10x1.5 plate cooler, 2qt accusump

Lipp 3" turbo elbow

2.5" Turbo hotside to 2.5" spearco replica, reduced to OEM for fender pipe to TB

Maft-Pro

OEM fuel

etc

Every bolt gets loctite blue or red, or antiseize. Exhaust and EGR gaskets get Permatex copper silicone, all other gaskets/surfaces sealed with 'Right-Stuf' sealant

Important gaskets (EGR, exhaust, turbo, lower intake) are Toyota.

Main seals, oil pump drive seal are rock auto specials.

Freeze plugs are Toyota, sealed with Permatex #1a (hard-setting) and staked.

I'm dave. I haven't formerly introduced myself though some may know me from here and there when i do speak up.

THIS, my car experience, this thread, wouldn't have happened without Supramania.

I used to be the clothes horse dude that while ambitious, didn't get greasy beyond the easy cleaning of my hands basic maintenance involves.

There are dozens on here to thank for the advice and info, parts purchased, even life guidance from that couple whose intensity overshadows their muted input, the man who makes this site possible.

Enough with the heart felt speech, to the point

Working on these cars can be fun or a total bitch. At least they're old enough to be easily worked on.

Going custom, that is where you hurry up to make progress and wait for more parts when you get stuck.

Like anyone else, I get motivated and sick of working on the supra. The pay off is extraordinary and boost is addicting; finding a good settling point, that is the hard part.

I picked a goal several years back and have based this build on a bolt-on turbo I picked up from jbkmkiii

This is my progress over the years to now, fast forwarded and omitting some minor details.

But first, how I came across the Supra

History:

I was tired of hauling broke people around that didn't pitch in for gas and wanted something to show for my money instead of blowing all my cash on bills and partying.

The fix, get a 2 seater.

Not just any 2 seater. It had to be economical (*cough*Bullshit...), and have balls enough that hills didn't slow it down to 45mph.

At the time i was rolling to Santa Cruz a lot and Hwys 680-880-17 has long grades where if I wasn't doing 70+, i was stuck doing 45 with my 93 Ford AEROSTAR van.

That bucket was the shit, mind you. I've rolled 12 deep to parties and got them poppin!

So my trips to SC was usually 6-7 ppl, ice chest, a mix match of skin boards boogie boards surf boards, and 2 fosgate powered Alpine X 12s hammering out 800 watts, so many memories...

The Aerostar was a hand-me-down. I had to have my own.

Mustangs and camaros were everywhere. This called for picking something different.

Hopped on craigslist and looked for something reasonable, respectable, easy to work on, dependable.

Caddys, 240s, s10s.

But the supra was love on first site. Dropped on H&R springs, HRE 5 spoke rims, the paint that don't tell the fuzz "here i am". Perfect.

Anyone remember CkAnderson? My car was his sister's for a brief moment. I believe I'm the fifth owner.

An example of what I saw on craigslist, though this pic is years later:

February 2nd, 2009

30 minutes north of Gorda Springs Resort, Hwy 1

Minus the 'shaved' handles, of course.

It got stolen on May 10th, 2006 and I put out the word to some Supra buddies who helped me recover it a day later, intact.

Anyways, there was this joke on Sf years back that supras are on jack stands 9 months of the year.

With this build, I hope to alleviate myself of that issue with sheer will... err uh I mean pilesOcash

Built Block-

-Eagle Rods

-Arias pistons, .020 overbore (84mm, 83.5 is oem)

-ARZ upgraded oil pump crossover tube

-5mm shimmed oil pump pressure relief

-5mm shimmed oil pump pick up

-ACL bearings, STD size

-Block decked about .020" for 2mm HKS Stopper

-ARP Head Studs torqued to 85 ft/lbs

-ARP Series 2000 3/8" (7/16" 12-point head) connecting Rod Bolts, 43 ft/lbs

-Main and Rod bearings set to .030

Built Head-

-Supertech Oversize valves, .5mm Intake and Exhaust

-BC Springs and Retainers

-BC 272 Cams

-mild porting, gasket matched intake

-Toyota valve stems and valve seals, cam seals

-Ferrera adjustable cam gears

-Gates performance timing belt (blue)

Turbo- Bolt-on T70

AN-10 oil system with 8x10x1.5 plate cooler, 2qt accusump

Lipp 3" turbo elbow

2.5" Turbo hotside to 2.5" spearco replica, reduced to OEM for fender pipe to TB

Maft-Pro

OEM fuel

etc

Every bolt gets loctite blue or red, or antiseize. Exhaust and EGR gaskets get Permatex copper silicone, all other gaskets/surfaces sealed with 'Right-Stuf' sealant

Important gaskets (EGR, exhaust, turbo, lower intake) are Toyota.

Main seals, oil pump drive seal are rock auto specials.

Freeze plugs are Toyota, sealed with Permatex #1a (hard-setting) and staked.

I'm dave. I haven't formerly introduced myself though some may know me from here and there when i do speak up.

THIS, my car experience, this thread, wouldn't have happened without Supramania.

I used to be the clothes horse dude that while ambitious, didn't get greasy beyond the easy cleaning of my hands basic maintenance involves.

There are dozens on here to thank for the advice and info, parts purchased, even life guidance from that couple whose intensity overshadows their muted input, the man who makes this site possible.

Enough with the heart felt speech, to the point

Working on these cars can be fun or a total bitch. At least they're old enough to be easily worked on.

Going custom, that is where you hurry up to make progress and wait for more parts when you get stuck.

Like anyone else, I get motivated and sick of working on the supra. The pay off is extraordinary and boost is addicting; finding a good settling point, that is the hard part.

I picked a goal several years back and have based this build on a bolt-on turbo I picked up from jbkmkiii

This is my progress over the years to now, fast forwarded and omitting some minor details.

But first, how I came across the Supra

History:

I was tired of hauling broke people around that didn't pitch in for gas and wanted something to show for my money instead of blowing all my cash on bills and partying.

The fix, get a 2 seater.

Not just any 2 seater. It had to be economical (*cough*Bullshit...), and have balls enough that hills didn't slow it down to 45mph.

At the time i was rolling to Santa Cruz a lot and Hwys 680-880-17 has long grades where if I wasn't doing 70+, i was stuck doing 45 with my 93 Ford AEROSTAR van.

That bucket was the shit, mind you. I've rolled 12 deep to parties and got them poppin!

So my trips to SC was usually 6-7 ppl, ice chest, a mix match of skin boards boogie boards surf boards, and 2 fosgate powered Alpine X 12s hammering out 800 watts, so many memories...

The Aerostar was a hand-me-down. I had to have my own.

Mustangs and camaros were everywhere. This called for picking something different.

Hopped on craigslist and looked for something reasonable, respectable, easy to work on, dependable.

Caddys, 240s, s10s.

But the supra was love on first site. Dropped on H&R springs, HRE 5 spoke rims, the paint that don't tell the fuzz "here i am". Perfect.

Anyone remember CkAnderson? My car was his sister's for a brief moment. I believe I'm the fifth owner.

An example of what I saw on craigslist, though this pic is years later:

February 2nd, 2009

30 minutes north of Gorda Springs Resort, Hwy 1

Minus the 'shaved' handles, of course.

It got stolen on May 10th, 2006 and I put out the word to some Supra buddies who helped me recover it a day later, intact.

Anyways, there was this joke on Sf years back that supras are on jack stands 9 months of the year.

With this build, I hope to alleviate myself of that issue with sheer will... err uh I mean pilesOcash

Last edited: