Well got my motor off to the machine shop again and i have it all done up right this time(thank you everyone for your help). So today i started on the polishing part of my build. my plans are to paint the block and polish the valve covers, the intake, the coolant intake, the timing cover and my bell housing. So i started on the valve covers. First step i used a wire wheel to strip the paint off. Then i hand sanded with 220 grit, then 320 grit, then polished off with 1200 grit. Should i use a finer grit in between the 320 and 1200? also i am doing the sanding by hand is there any better of a way to do this?

Polishing Question

- Thread starter JStoked

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

you should use a 600 or 800 in between the 340 and 1200. i usually finish mine with 2000 grit with water after the 1200 or 1500 depending on what i have around.

I wouldnt start that low of grit. Its just going to take more time and your just going to create more gouges and scoring than anything. I would start at 400-600 depending on how rough the surface is than gradually go up to 800-1000-1200-1500-2000.

SUPERIUM;1685747 said:I wouldnt start that low of grit. Its just going to take more time and your just going to create more gouges and scoring than anything. I would start at 400-600 depending on how rough the surface is than gradually go up to 800-1000-1200-1500-2000.

True but it gets all the ruff edges off faster. I am going for a nice smooth look. if i could figure out how to get the rigged lines off and just have a nice smooth look is what im going for with my 2jz coils.

Bump I know people have takin the lines off the Valve covers I plan on trying a 4 inch grinder is this ok?

Rajunz;1687562 said:

OOOOHHOO thank you very much man!!!!!

If you want to get rid of the lines on top of the valve covers the best thing would be a belt sander. As for when I started polishing I used a random orbital sander with 220 grit then moved to 460 then 800 then wet sand with 1000 lastly hand buff with a terry cloth and mothers aluminum polish until the part shined. Now I have a free standing buffer with a 3 hp motor and 12" wheels that makes doing almost anything a breeze.

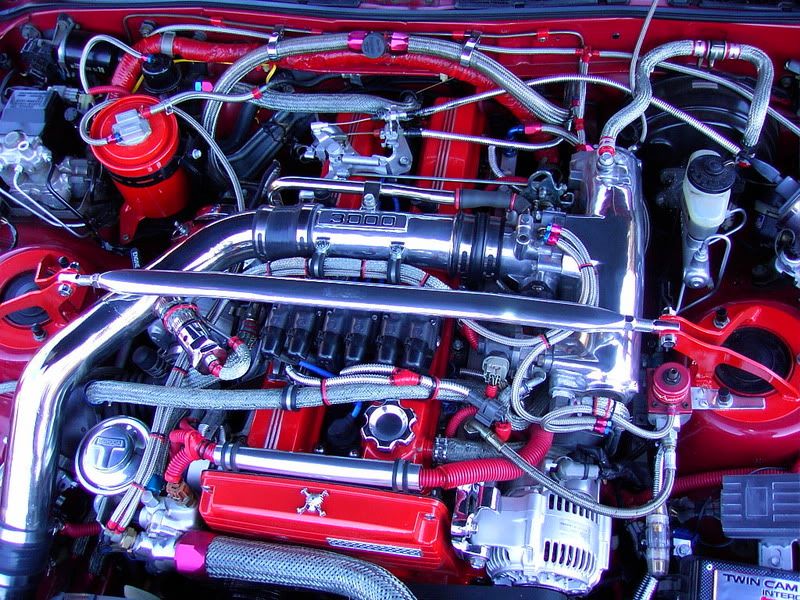

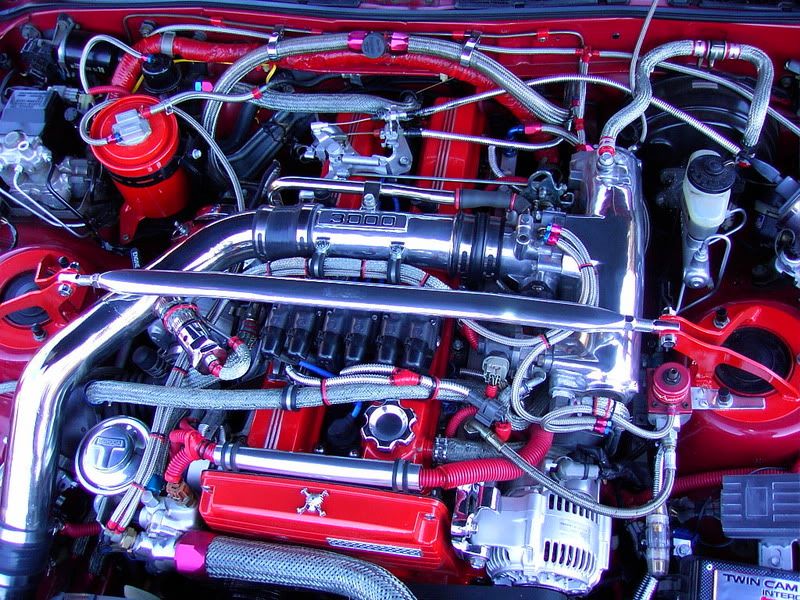

I will tell you though you have to treat the part some how or it will oxidize and all the work will be for nothing. Here is some of the stuff I did by hand.

I will tell you though you have to treat the part some how or it will oxidize and all the work will be for nothing. Here is some of the stuff I did by hand.

Go to a Semi Truck parts house in your area, they have really good Busch polish and sealant, or just order it here.

http://www.flynndist.com/products/busch-aluminum-wax-and-sealant

http://www.flynndist.com/products/busch-aluminum-wax-and-sealant