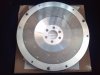

Just to show the finished product. I built a hopper on the bottom, a hatch for the end and got all the needed extras for the inside. The blasting kit purchased at Menards as well as the blasting media and some toilet flanges to hold the sleeves. I also picked up a set of heavy Hobart welding sleeves from Farm & Fleet and attached them inside to protect my arms. For the gloves, I've just been using my old pairs of Mechanix gloves.

After all was said and done, I spent about $50-$60 on building this thing for cleaning my parts. Works just as good as a purchased one and considering the price difference, I couldn't go wrong. Definitely some things I would change doing it again but that is a project for another time.

After all was said and done, I spent about $50-$60 on building this thing for cleaning my parts. Works just as good as a purchased one and considering the price difference, I couldn't go wrong. Definitely some things I would change doing it again but that is a project for another time.

![2011-03-10 00.44.32[4].jpg 2011-03-10 00.44.32[4].jpg](https://www.supramania.com/data/attachments/30/30271-5e6e789e0cb778513772d84c92ab011f.jpg)