Ok, so a couple weeks ago i ran into a little electrical problem. My fuel pump wires and relay burnt up on me and the wires melted and shorted out. Left me stranded on the side of the road. Well, today i go out there to rewire them using 10awg primary wire to a relay that is rated for a little better performance. I find out that one fuel pump is dead or is still shorted out. I'm running the new wire right from the top of the fuel pump hanger. I made a little hole in the trunk to access the wires. I get a spark when i touch the POS wire to the battery, it's just not pumping... the other one works fine.

i have 2 fuel pumps and 2 fuel lines going to my dual feed fuel rail. is it ok to drive it with only one fuel pump on? will the other fuel pump hold the pressure and basically act as a closed valve?

i started the engine, idles great, fuel pressure is holding a steady 35psi... when i rev the motor the pressure rises and doesn't fall.

i don't have the time or the money to take a look and possibly buy another fuel pump.

oh, and what does N.C and N.O mean on the wiring diagrams for relays.

COIL1= to positive battery terminal

COIL2= to ground

COMM= power input from battery

N.C= resting state for relay

N.O= accessory

the relay that failed on me said

>87a N.C 20 amps

>87 N.O 50 amps

does it mean NON CONTINUOUS. i don't know what the N.O means

the new one i bought was $13 more to purchase. so it must be rated for more current. it says continuous out 25 amps.

i know i could just wire it up to the battery, but i don't want this thick wire inside the car adding so many feet to get to the fuel pumps, i wanted the shortest path possible for it.

and also, my timing is 0 degrees for cams and 3-4 BTDC on the crank, should i zero it all out or will it be fine how it is? i'm also gonna rerun new wires from the coils to the igniter, they are all cracked and wire is exposed and looks corroded.

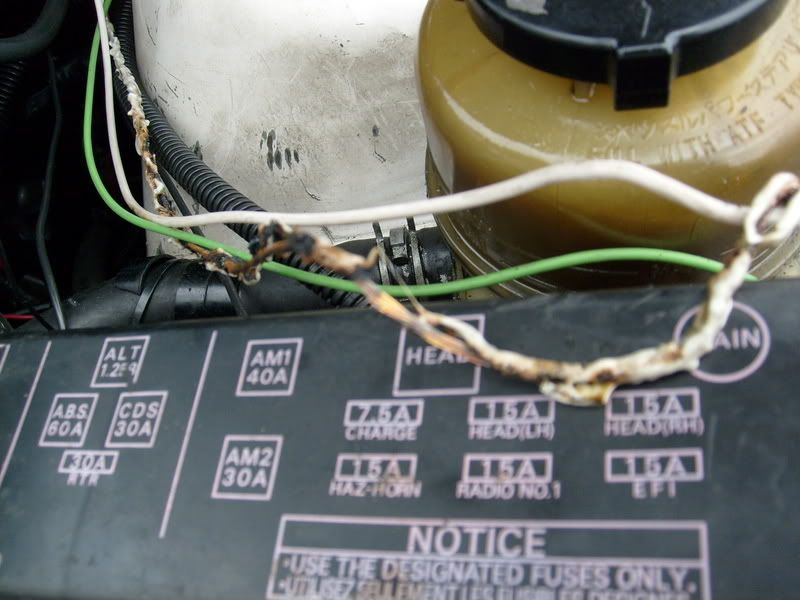

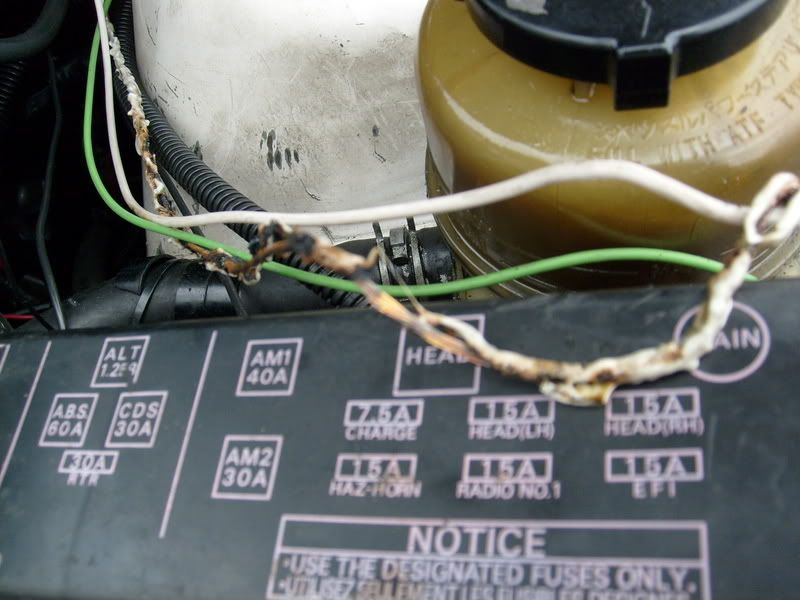

this is what happened to me before, i used 16 awg wire for each pump connected to one terminal on the relay.

i have 2 fuel pumps and 2 fuel lines going to my dual feed fuel rail. is it ok to drive it with only one fuel pump on? will the other fuel pump hold the pressure and basically act as a closed valve?

i started the engine, idles great, fuel pressure is holding a steady 35psi... when i rev the motor the pressure rises and doesn't fall.

i don't have the time or the money to take a look and possibly buy another fuel pump.

oh, and what does N.C and N.O mean on the wiring diagrams for relays.

COIL1= to positive battery terminal

COIL2= to ground

COMM= power input from battery

N.C= resting state for relay

N.O= accessory

the relay that failed on me said

>87a N.C 20 amps

>87 N.O 50 amps

does it mean NON CONTINUOUS. i don't know what the N.O means

the new one i bought was $13 more to purchase. so it must be rated for more current. it says continuous out 25 amps.

i know i could just wire it up to the battery, but i don't want this thick wire inside the car adding so many feet to get to the fuel pumps, i wanted the shortest path possible for it.

and also, my timing is 0 degrees for cams and 3-4 BTDC on the crank, should i zero it all out or will it be fine how it is? i'm also gonna rerun new wires from the coils to the igniter, they are all cracked and wire is exposed and looks corroded.

this is what happened to me before, i used 16 awg wire for each pump connected to one terminal on the relay.