I just picked up a HKS 3000 pipe and was thinking of running dual BOV...

Why?

I'm running a 62-1 upgrade and I want to make sure enough pressure is released so to protect the Turbo.

The BOV are faily cheap and I already have one.

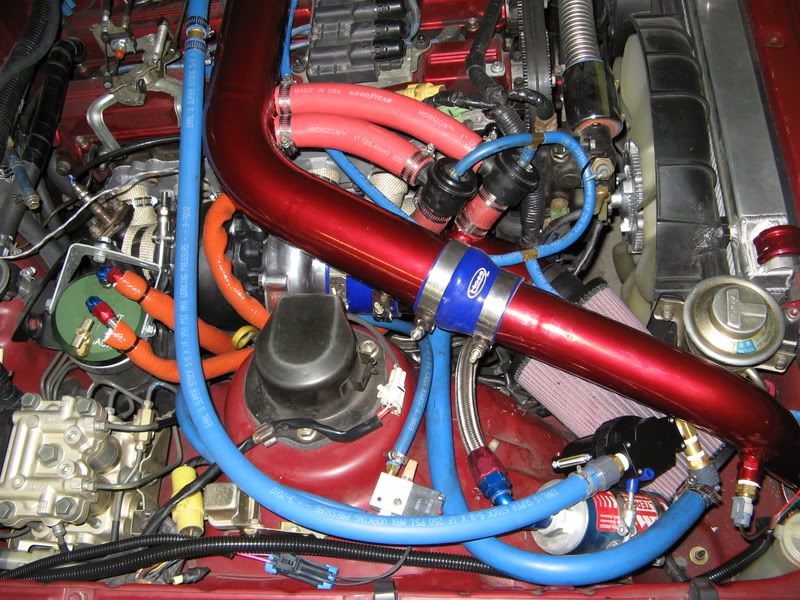

I can drill and tap some fittings into my aluminum IC pipes just infront of the HKS to allow for a BOV.

No flange or additional joint in the IC.

I know someone has done it as I remember seeing a pic of an engine bay with dual BOV.

So....

Does anyone know who that was?

What are your thoughts on this? Please keep it technical and not post an opinion or your "feelings"

Would this be pointless as both BOV would be trying to recurculate through the same small hole in the accordion hose.?

Alternatives in the same price range (~$100)?

Why?

I'm running a 62-1 upgrade and I want to make sure enough pressure is released so to protect the Turbo.

The BOV are faily cheap and I already have one.

I can drill and tap some fittings into my aluminum IC pipes just infront of the HKS to allow for a BOV.

No flange or additional joint in the IC.

I know someone has done it as I remember seeing a pic of an engine bay with dual BOV.

So....

Does anyone know who that was?

What are your thoughts on this? Please keep it technical and not post an opinion or your "feelings"

Would this be pointless as both BOV would be trying to recurculate through the same small hole in the accordion hose.?

Alternatives in the same price range (~$100)?