Ive had my DDP for almost 3 years now.

I love the wastegate dump noise and without it, it feels like something's missing.

I recently installed my new quiet catback and swapped out my DDP for my spare HKS 3" DP just to enjoy silence for a little while.

I can definetly notice the power difference from one downpipe to the other.

The DDP is definetly going back in, i just thought id take a crack at fixing its quirk.

So the DDP leaks from a poor seal of the exhaust hole and the wastegate hole.

This causes a exhaust leak under normal operation out the dump tube. This also increases drone under cruising and such.

If it could be sealed, it would be golden.

Here's a couple of my ideas.

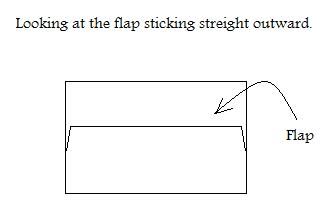

Not too sure on a good solution here. Was thinking about some kind of exhaust crush sealing material to seal the two sides.

----------------------------------------------------------------

This was my genious idea, but maybe a little complex.

Y-pipe with a vacuum operated cutout.

A bunch of audi's have this vacuum operated exhaust valve on the rear muffler to make a more aggressive tone when you're on it. I work at an audi shop, so i thought maybe i can score one somehow.

Having a recirc and open WG option at the touch of a switch seems pretty nifty.

This is the valve on an R32. same shit

--------------------------------------------------------------------------

[/IMG]

[/IMG]

This may be my best solution.

I HAVE an electric cutout right after my downpipe.

Right now i'm running the HKS 3" DP and when the cutout is open, i cant hear the wastegate. I don't like that.

If i use my DDP and lets say its recirculated back into the exhaust about foot or 2 away from the cutout..Will it sound like an open wastegate dump with the cutout open?

If so, thats my perfect solution.

Thoughts, comments, suggestions appreciated.

Discuss.

I love the wastegate dump noise and without it, it feels like something's missing.

I recently installed my new quiet catback and swapped out my DDP for my spare HKS 3" DP just to enjoy silence for a little while.

I can definetly notice the power difference from one downpipe to the other.

The DDP is definetly going back in, i just thought id take a crack at fixing its quirk.

So the DDP leaks from a poor seal of the exhaust hole and the wastegate hole.

This causes a exhaust leak under normal operation out the dump tube. This also increases drone under cruising and such.

If it could be sealed, it would be golden.

Here's a couple of my ideas.

Not too sure on a good solution here. Was thinking about some kind of exhaust crush sealing material to seal the two sides.

----------------------------------------------------------------

This was my genious idea, but maybe a little complex.

Y-pipe with a vacuum operated cutout.

A bunch of audi's have this vacuum operated exhaust valve on the rear muffler to make a more aggressive tone when you're on it. I work at an audi shop, so i thought maybe i can score one somehow.

Having a recirc and open WG option at the touch of a switch seems pretty nifty.

This is the valve on an R32. same shit

--------------------------------------------------------------------------

This may be my best solution.

I HAVE an electric cutout right after my downpipe.

Right now i'm running the HKS 3" DP and when the cutout is open, i cant hear the wastegate. I don't like that.

If i use my DDP and lets say its recirculated back into the exhaust about foot or 2 away from the cutout..Will it sound like an open wastegate dump with the cutout open?

If so, thats my perfect solution.

Thoughts, comments, suggestions appreciated.

Discuss.

Last edited: