There’s many ways to upgrade your fuel system, this is just one of the ways to do it. This fuel set-up is to support a PT67 on a 1.5jz. For fuel (and ignition) management I use the eman blue in combination with a Blitz ecu, works nice.

Old situation: in-tank walbro, mkiv 550’s

The upgrades:

Sard 800cc injectors, side feed

2 Walbro 255l/h High Pressure pumps (GSS341)

Aeromotive adjustable fuel pressure regulator w gauge

Modified stock fuel rail

Hobbs switch

Separate feed line

I have chosen for an in-line pump because I am convinced two pumps next to each other in-tank need magnetic shielding. They will work without it, that’s why people say it’s ok, but they will not perform to their max. potential as the magnetic fields do interfere with each other without magnetic shielding. As I didn’t had any magnetic shielding handy and couldn’t get to it quick enough I opted for an inline pump. It has the exact same specs as the in-tank version.

This second pump is switched by a Hobbs switch. As my car is a daily driver I don’t want and need that much fuel being pumped around all the time, as it will only heat up the fuel. So it kicks in at a set boost level which is adjustable on the one I have.

I ran a separate feed line, didn’t take any pics of this, sorry. I followed the stock route with a flexible rubber line with shielding for some protection. As the pump is up front this line is not pressurized so you won’t need a steel braided line. For the in-tank pick up I used a steel tube with a pick up filter from a stock mkiii pump which I ran along the in-tank pump. You need to remove your tank for installing the pick up.

The second pump is mounted on the sub frame. Walbro provides brackets and a rubber sleeve for dampening with the in-line pump. I drilled two holes and used thick self tapping bolts to fix the pump. If you decide to mount it in this spot, attach both lines first before you bolt the pump down, it’s easier that way. Here you can see it sitting at the bottom.

Here you can see the ground wire already connected. This wire is connected to the body right next to the pump, there are a few bolts you can use there to hook the ground wire up to. The 12V wire is not connected yet here.

Next in the routing is the filter. I have chosen for a mkiv filter because it’s compact and the stock mkiv pump has a similar flow as the walbro.

This to me looked like a nice place to mount the filter as I didn’t need to drill more holes.

I slightly modified the filter to mount it, see pic below. I took off the heat shield and filed off a bit from the bracket.

Don’t you just love Toyota? Two of the three holes of the filter bracket line up perfectly with the two mounting bolts of this brake collector block. I can’t remember if the filter needs to be turned around in the bracket to put it in the right flow direction, it’s been some time when I did this. Here you can see it mounted.

Here’s another pic with the lines hooked up. Make sure the line and wires can’t touch the steering axle.

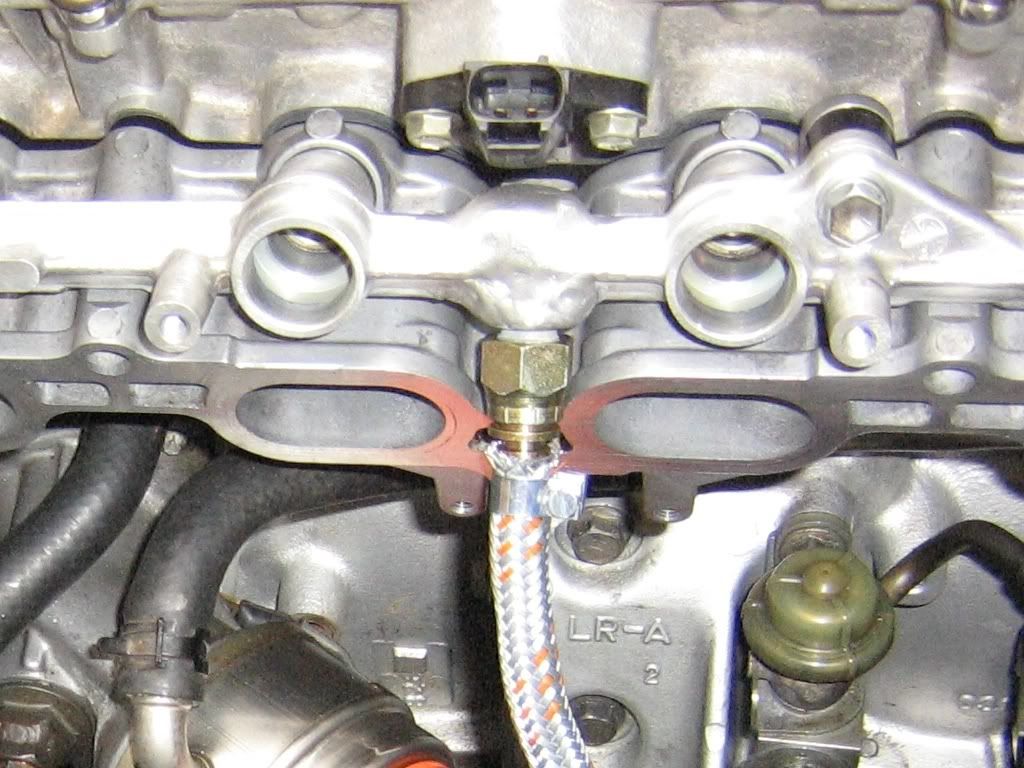

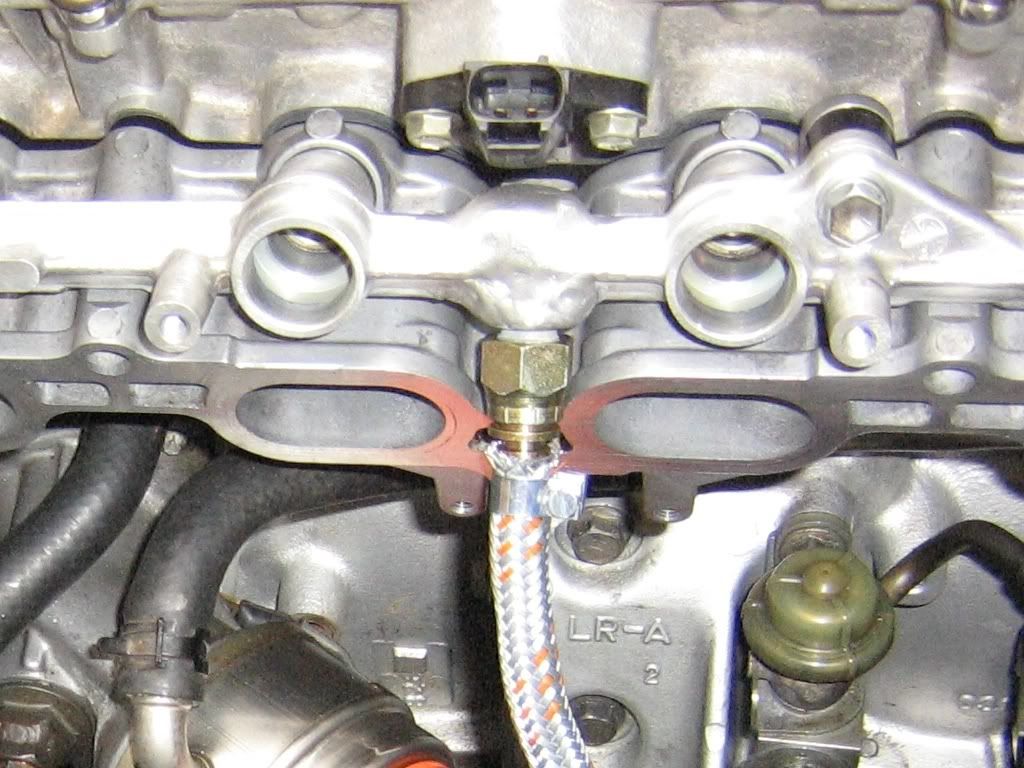

The stock fuel rail is modified so it now has a centre return and feed at both ends. This return has to go between intake runner 3 and 4. Now this is not in the exact middle of the rail, it’s a few millimeters to the back and needs to be angled slightly. See picks below.

Here you can see how it fits in between the runners.

For the feeds I’ve kept the stock feed at the back. The second pump will feed at the front where the stock fpr used to be. For this I’ve used the same banjo bolt as the one at the back, it fits without modification.

Note: If you’re at the limit of one pump and you want to get the most of it, banjo’s are not the way to go, they do provide resistance to the flow. But as I’m aiming at only 500rwhp on pump gas I can afford to sacrifice some flow as the dual pumps will flow more than enough for my needs.

Last item in the routing is the adjustable fuel pressure regulator.

The return line from the fuel rail goes to one of the side ports, the return line connects to the bottom port and is hooked up to the stock return line. The vacuum line hooks up to somewhere on the intake manifold.

I have set the fuel pressure a little higher than what the tsrm says to improve the idle with the large injectors; the higher pressure works against the magnetic valves in the injector which decreases the opening time slightly. The problem with large injectors is that the smallest dutycycle still delivers too much fuel for smooth idling.

To test the set-up for leaks, switch the ignition to on and connect B+ to Fp on the diagnostic plug, this will make the fuel pump run. A leak will mostly appear as a spray rather than drops because of the pressure in the lines, be careful with that. If there are no leaks in this mode, pinch the return line below the fpr, this will make the pressure rise and test the set-up further.

With the fuel pump still running, you can now adjust the fpr roughly to the desired pressure.

The final adjustment of the fuel pressure needs to be done with the vacuum line unhooked and the engine running.

Old situation: in-tank walbro, mkiv 550’s

The upgrades:

Sard 800cc injectors, side feed

2 Walbro 255l/h High Pressure pumps (GSS341)

Aeromotive adjustable fuel pressure regulator w gauge

Modified stock fuel rail

Hobbs switch

Separate feed line

I have chosen for an in-line pump because I am convinced two pumps next to each other in-tank need magnetic shielding. They will work without it, that’s why people say it’s ok, but they will not perform to their max. potential as the magnetic fields do interfere with each other without magnetic shielding. As I didn’t had any magnetic shielding handy and couldn’t get to it quick enough I opted for an inline pump. It has the exact same specs as the in-tank version.

This second pump is switched by a Hobbs switch. As my car is a daily driver I don’t want and need that much fuel being pumped around all the time, as it will only heat up the fuel. So it kicks in at a set boost level which is adjustable on the one I have.

I ran a separate feed line, didn’t take any pics of this, sorry. I followed the stock route with a flexible rubber line with shielding for some protection. As the pump is up front this line is not pressurized so you won’t need a steel braided line. For the in-tank pick up I used a steel tube with a pick up filter from a stock mkiii pump which I ran along the in-tank pump. You need to remove your tank for installing the pick up.

The second pump is mounted on the sub frame. Walbro provides brackets and a rubber sleeve for dampening with the in-line pump. I drilled two holes and used thick self tapping bolts to fix the pump. If you decide to mount it in this spot, attach both lines first before you bolt the pump down, it’s easier that way. Here you can see it sitting at the bottom.

Here you can see the ground wire already connected. This wire is connected to the body right next to the pump, there are a few bolts you can use there to hook the ground wire up to. The 12V wire is not connected yet here.

Next in the routing is the filter. I have chosen for a mkiv filter because it’s compact and the stock mkiv pump has a similar flow as the walbro.

This to me looked like a nice place to mount the filter as I didn’t need to drill more holes.

I slightly modified the filter to mount it, see pic below. I took off the heat shield and filed off a bit from the bracket.

Don’t you just love Toyota? Two of the three holes of the filter bracket line up perfectly with the two mounting bolts of this brake collector block. I can’t remember if the filter needs to be turned around in the bracket to put it in the right flow direction, it’s been some time when I did this. Here you can see it mounted.

Here’s another pic with the lines hooked up. Make sure the line and wires can’t touch the steering axle.

The stock fuel rail is modified so it now has a centre return and feed at both ends. This return has to go between intake runner 3 and 4. Now this is not in the exact middle of the rail, it’s a few millimeters to the back and needs to be angled slightly. See picks below.

Here you can see how it fits in between the runners.

For the feeds I’ve kept the stock feed at the back. The second pump will feed at the front where the stock fpr used to be. For this I’ve used the same banjo bolt as the one at the back, it fits without modification.

Note: If you’re at the limit of one pump and you want to get the most of it, banjo’s are not the way to go, they do provide resistance to the flow. But as I’m aiming at only 500rwhp on pump gas I can afford to sacrifice some flow as the dual pumps will flow more than enough for my needs.

Last item in the routing is the adjustable fuel pressure regulator.

The return line from the fuel rail goes to one of the side ports, the return line connects to the bottom port and is hooked up to the stock return line. The vacuum line hooks up to somewhere on the intake manifold.

I have set the fuel pressure a little higher than what the tsrm says to improve the idle with the large injectors; the higher pressure works against the magnetic valves in the injector which decreases the opening time slightly. The problem with large injectors is that the smallest dutycycle still delivers too much fuel for smooth idling.

To test the set-up for leaks, switch the ignition to on and connect B+ to Fp on the diagnostic plug, this will make the fuel pump run. A leak will mostly appear as a spray rather than drops because of the pressure in the lines, be careful with that. If there are no leaks in this mode, pinch the return line below the fpr, this will make the pressure rise and test the set-up further.

With the fuel pump still running, you can now adjust the fpr roughly to the desired pressure.

The final adjustment of the fuel pressure needs to be done with the vacuum line unhooked and the engine running.