Urethane foam injection for increased chassis rigidity...?

- Thread starter yannis-supras

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Post on mkiiitech, linked to the SF thread as well.

http://www.mkiiitech.com/forums/viewtopic.php?t=130

http://www.mkiiitech.com/forums/viewtopic.php?t=130

Thanks for all the links and info guys. outofstep I found your sf thread and it was very informative indeed. Nice finds on the shops for the foam as well :bigthumb:. I was thinking of going for the 3M stuff that is much densier than the material used on the Z (3M 10lbs/ft - HandiFoam 2lbs/ft) but it requires a special spray gun that is about $70 so I think it is cheaper to get the foam from this link that you posted as well http://www.betterfoam.com/TwoComponent/tabid/180/Default.aspx.

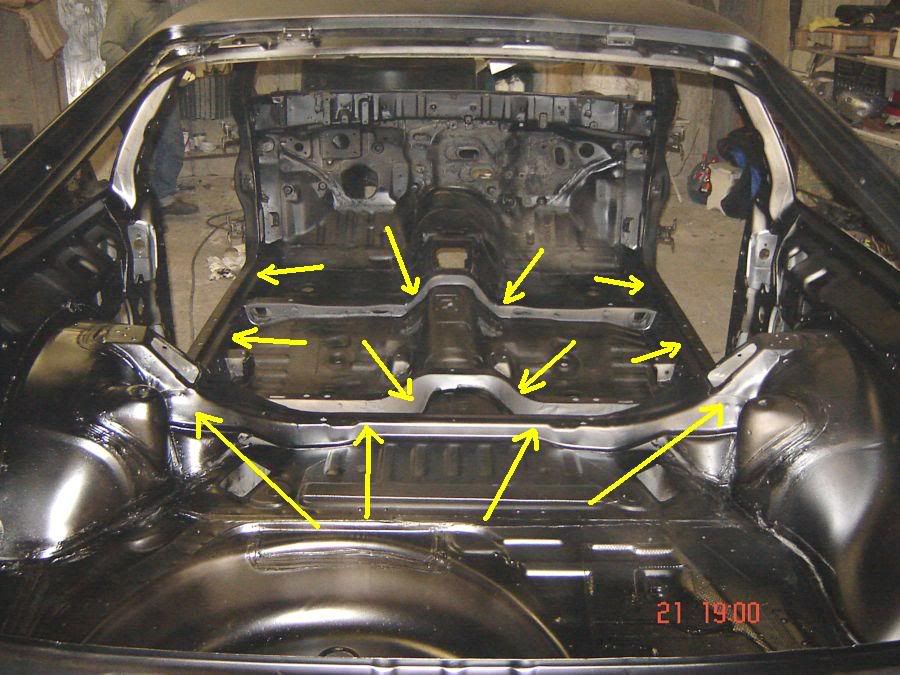

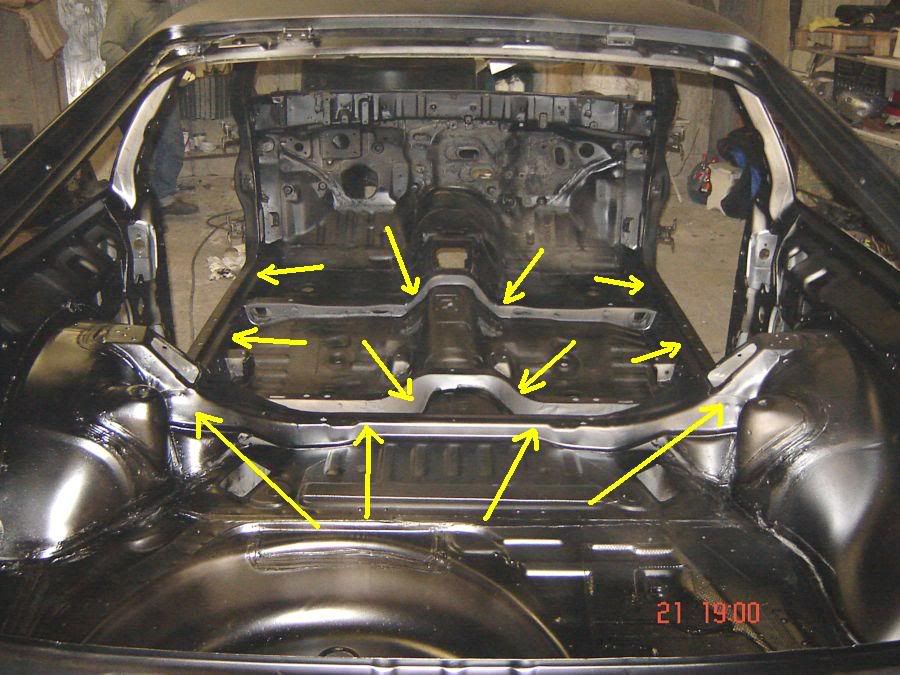

Ok now I've pointed out the areas that I'm thinking of foam injecting:

It's basically all the transverse cross members and the sidesills. I have stich welded the seams on the sidesills by now and I will be doing the same on all the transverse cross members prior to foam injection. Good thing is that all those crossmembers are full of holes and gaps so no need to punch any more holes for the foam to get relief.

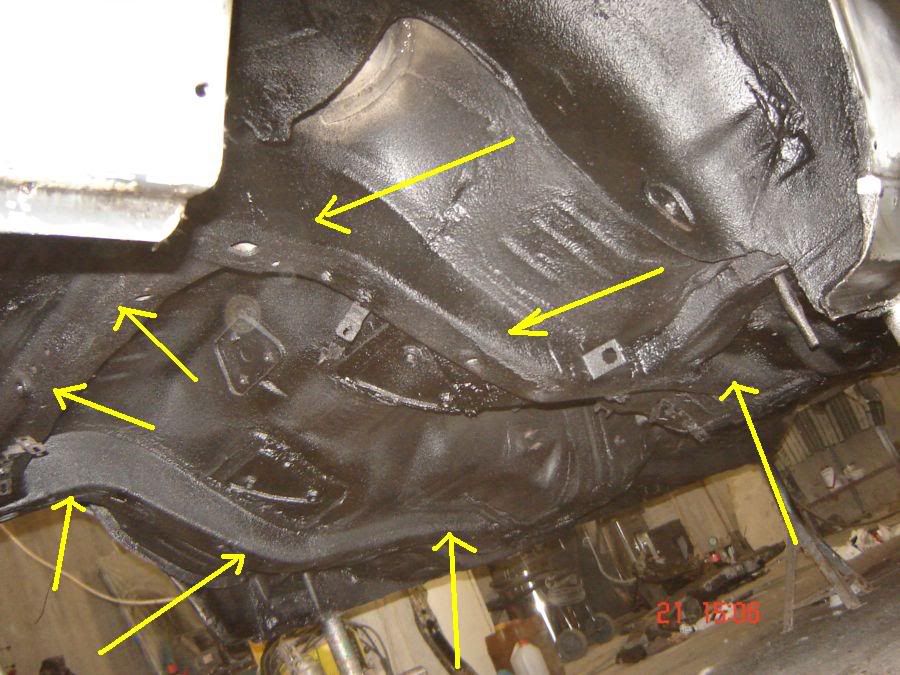

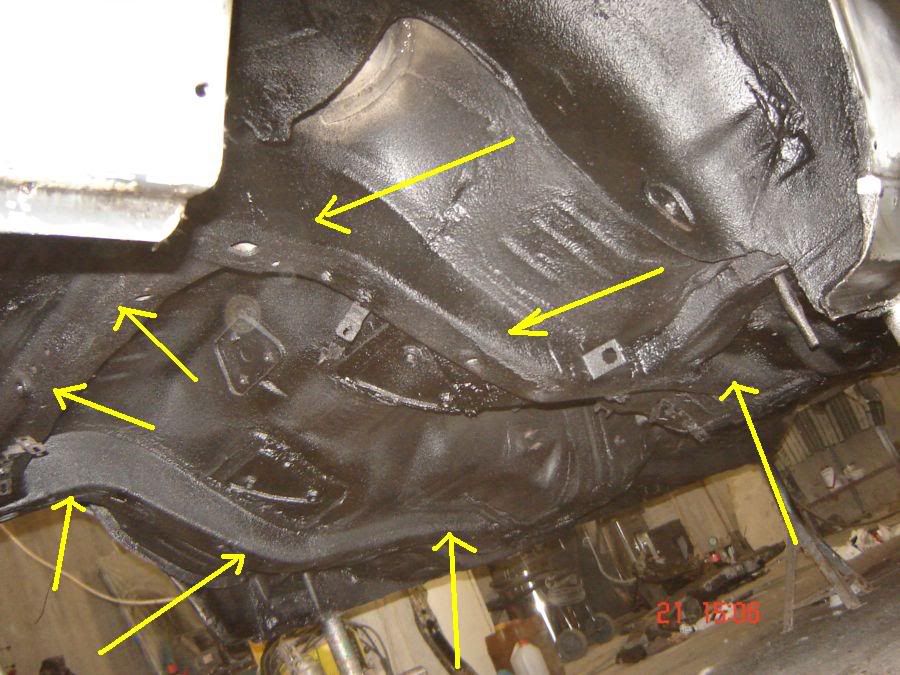

And I'm also thinking of injecting the main frame all the way from front to rear:

I'm still not sure about the front ends of the main frame rails in the engine bay though. I'm not quite sure how that would effect chassis crumpling.

Ok now I've pointed out the areas that I'm thinking of foam injecting:

It's basically all the transverse cross members and the sidesills. I have stich welded the seams on the sidesills by now and I will be doing the same on all the transverse cross members prior to foam injection. Good thing is that all those crossmembers are full of holes and gaps so no need to punch any more holes for the foam to get relief.

And I'm also thinking of injecting the main frame all the way from front to rear:

I'm still not sure about the front ends of the main frame rails in the engine bay though. I'm not quite sure how that would effect chassis crumpling.

Last edited:

Ok I just bought 5 of those http://cgi.ebay.com/ebaymotors/3M-A...goryZ63702QQihZ002QQitemZ4625737309QQtcZphoto. Well I finally went for the 3M stuff. Getting HandiFoam in the right density and quantity was getting a pita to establish so I decided to buy what I originally preffered. The guys from Sport Compact mag used 3 HandiFoam containers so I got 5 of the 3M as it's a densier material. Hopefully that'll be enough.

How did you find out the desity of the 3M product? I went to the 3M site and it didn't say anything about it's density.

If you go on this page http://products3.3m.com/catalog/us/...us_aad_3_0/command_AbcPageHandler/output_html download the MSDS (United States) pdf file. That's the data sheet of the material. On section 9, page 7, is the material's properties.Racefiend said:How did you find out the desity of the 3M product? I went to the 3M site and it didn't say anything about it's density.

...although now that I re-read it I realized it says that it's 10.4lb/gal.....:aigo: :wuteva:,that's gallon not foot so compared to the 2lb/ft of HandiFoam value this doesn't really make any sense

Any physics scientists around???

yannis-supras said:If you go on this page http://products3.3m.com/catalog/us/...us_aad_3_0/command_AbcPageHandler/output_html download the MSDS (United States) pdf file. That's the data sheet of the material. On section 9, page 7, is the material's properties.

...although now that I re-read it I realized it says that it's 10.4lb/gal.....:aigo: :wuteva:,that's gallon not foot so compared to the 2lb/ft of HandiFoam value this doesn't really make any sense. I mean 10.4lb/gal is equivilant to 77.8lb/ft, cubic foot that is. So I'm getting really confused now.

Any physics scientists around???

Ahh, I didn't see that in the msds when I glanced at it.

Anyways, the 10.4 is for part A. Then there is the msds for part B, which is 8.4 lb/gallon. I think it's a 50/50 mix, so you would get an average of 9.4 lb/gallon, which would equal 70.3 lb/ft3. Now this stuff expands 10X according to the site, so I would THINK that the actual density is 7lbs/ft3??

Yeap you're right on the 50/50 mix bit. The rest of your rationalization sounds good too and most of all it does suit my plans perfectly :biglaugh:.Racefiend said:Ahh, I didn't see that in the msds when I glanced at it.

Anyways, the 10.4 is for part A. Then there is the msds for part B, which is 8.4 lb/gallon. I think it's a 50/50 mix, so you would get an average of 9.4 lb/gallon, which would equal 70.3 lb/ft3. Now this stuff expands 10X according to the site, so I would THINK that the actual density is 7lbs/ft3??

Let's hope that you're right...

Adjuster

Supramania Contributor

I was using some West System epoxy to demonstrate boat and RV repairs, and that stuff is amazing. (There is a filler that looks like little fuzzy cotton balls, and when you add it to the epoxy, it becomes like mayonaise and stays where you put it. (It does not expand however.) When cured, it's harder than the substrate material on many boats. (Wood.)

I wonder if they make an expanding foam in this stuff. I'll have to check, but like the 3M stuff, it's not cheap by any means.

The Ford foam is in the A posts, and it's heat expanded. (Expands when the unitized truck cab is baked after being e-coated.)

I belive the weight difference between the higher PSI two part foam and the lower PSI ones is pretty minimal compared to what your getting structure wise. The foam alone is not that strong IIRC, but it's ability to keep the metal that's around it in place under load is what improves the overall effect on your chassis. (Seriously reduces flex as the boxed areas become very resistant to being twisted or bowed in any direction.)

One thing I would NOT do is add any foam ahead of the strut towers, or behind the rear towers. (The upper location point of the struts.) These areas are designed to crush in a controlled manner that slows you down just right so your brain and internal organs don't get slammed into your skull or ribs and kill you. Filled with this foam, they would not crush right, and it's going to allow more energy transfer into you and other occupants of the Supra.

I would think filling the front and rear cradles/subframes would be a good idea. Steam cleaing them first is totally needed. Oiled metal does not allow for a good bond between the foam and the subframe ID. (possibly why that car creaked IJ? I'm just guessing, but that's a common problem. Especially if the car was Z-barted or had extra corrosion resistance sprayed into the panels. That stuff is waxy, tough to remove and is a problem when repairs to the rail are needed. The only good news is it's somewhat resiliant, and will self heal sometimes if the surface is only scratched.

I wonder if they make an expanding foam in this stuff. I'll have to check, but like the 3M stuff, it's not cheap by any means.

The Ford foam is in the A posts, and it's heat expanded. (Expands when the unitized truck cab is baked after being e-coated.)

I belive the weight difference between the higher PSI two part foam and the lower PSI ones is pretty minimal compared to what your getting structure wise. The foam alone is not that strong IIRC, but it's ability to keep the metal that's around it in place under load is what improves the overall effect on your chassis. (Seriously reduces flex as the boxed areas become very resistant to being twisted or bowed in any direction.)

One thing I would NOT do is add any foam ahead of the strut towers, or behind the rear towers. (The upper location point of the struts.) These areas are designed to crush in a controlled manner that slows you down just right so your brain and internal organs don't get slammed into your skull or ribs and kill you. Filled with this foam, they would not crush right, and it's going to allow more energy transfer into you and other occupants of the Supra.

I would think filling the front and rear cradles/subframes would be a good idea. Steam cleaing them first is totally needed. Oiled metal does not allow for a good bond between the foam and the subframe ID. (possibly why that car creaked IJ? I'm just guessing, but that's a common problem. Especially if the car was Z-barted or had extra corrosion resistance sprayed into the panels. That stuff is waxy, tough to remove and is a problem when repairs to the rail are needed. The only good news is it's somewhat resiliant, and will self heal sometimes if the surface is only scratched.

Wow Adjuster thanks a lot for the input! Quite some important points you've made here and you also shed some light in areas of doubt.

on the front

should I fill up the main frame rail upto the red line further ahead or the yellow line? And either way any good ideas for stopping the foam expanding beyond the desired limit?

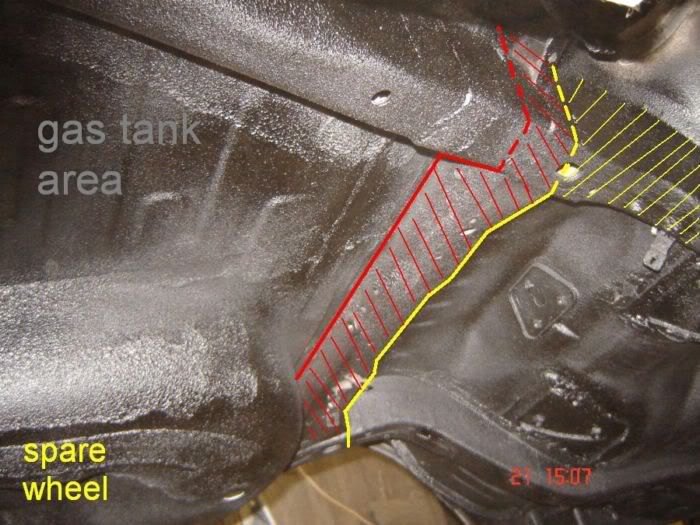

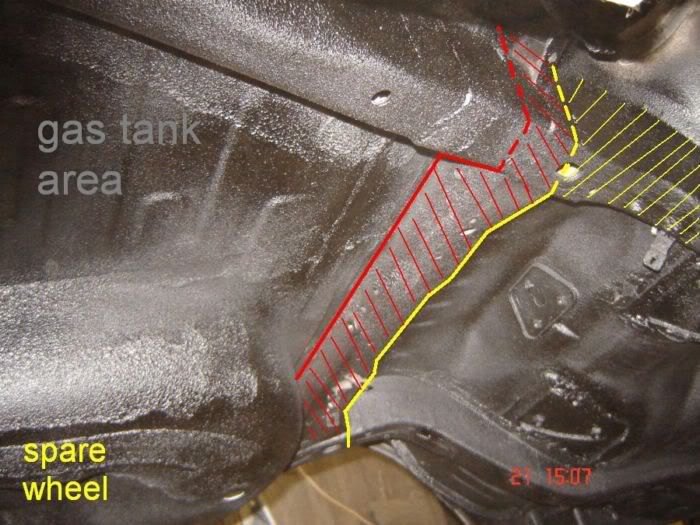

and on the rear

I guess I should fill up upto the crossmember that connects the towers, right? That's denoted with the red line on the pictures above. I hope they are clear enough so you can understand where is what...Same question about limiting foam expansion to the desired areas applies here also :icon_roll

My logic was making me lean towards the idea that weight differences should be minimal between the two but as you said the most important thing is the benefits in structural rigidity exactly as you described.Adjuster said:I belive the weight difference between the higher PSI two part foam and the lower PSI ones is pretty minimal compared to what your getting structure wise. The foam alone is not that strong IIRC, but it's ability to keep the metal that's around it in place under load is what improves the overall effect on your chassis. (Seriously reduces flex as the boxed areas become very resistant to being twisted or bowed in any direction.)

This is maybe the most crucial assesment on this modification in my opinion. It's essential to maintain those areas the way they were designed to function while achieving the highest possible rigidity by foam injection. So just to clarify things here and make sure that I'm getting this right:Adjuster said:One thing I would NOT do is add any foam ahead of the strut towers, or behind the rear towers. (The upper location point of the struts.) These areas are designed to crush in a controlled manner that slows you down just right so your brain and internal organs don't get slammed into your skull or ribs and kill you. Filled with this foam, they would not crush right, and it's going to allow more energy transfer into you and other occupants of the Supra.

on the front

should I fill up the main frame rail upto the red line further ahead or the yellow line? And either way any good ideas for stopping the foam expanding beyond the desired limit?

and on the rear

I guess I should fill up upto the crossmember that connects the towers, right? That's denoted with the red line on the pictures above. I hope they are clear enough so you can understand where is what...Same question about limiting foam expansion to the desired areas applies here also :icon_roll

Hmmm even though my car has just undergone a major restoration job and it's totally rust free I'm afraid that inside the main frame rails there must be some waxy corrosion resistant left. It was virtually impossible to get that stuff off of the floor of the car, let alone the insides of the rails :nono:. So I hope this will not create any major mishapps...Adjuster said:I would think filling the front and rear cradles/subframes would be a good idea. Steam cleaing them first is totally needed. Oiled metal does not allow for a good bond between the foam and the subframe ID. (possibly why that car creaked IJ? I'm just guessing, but that's a common problem. Especially if the car was Z-barted or had extra corrosion resistance sprayed into the panels. That stuff is waxy, tough to remove and is a problem when repairs to the rail are needed. The only good news is it's somewhat resiliant, and will self heal sometimes if the surface is only scratched.

Last edited:

Wow! This could be the final solution for eliminating targa shimmy and the need for an unsightly targa brace. I'm gonna try this for sure probably with the 16 lb foam. Will post my results.

** P.S. how can you effectively clean the inside of the rails i.e. rocker panels? A steam cleaner like the shark? At least it might push the dust and dirt to the ends..

** P.S. how can you effectively clean the inside of the rails i.e. rocker panels? A steam cleaner like the shark? At least it might push the dust and dirt to the ends..

Last edited:

Has anyone done this? If so I think the whole supra community would benefit from a good write up on the "How to" portion of the project. If not who is doing this out there in the world. If there is a shop in SoCal I will be there next week.

Those with a targa can appriciate the advantages of this product. Body flex without the top is a bitch....

Those with a targa can appriciate the advantages of this product. Body flex without the top is a bitch....

Well after further research, I'm going to do this, and report my application progress and results. I'm looking at either the 8 or 16 lb foam from this site: http://www.shopmaninc.com/foam.html

Check out the descriptions of the these densities:

"8lb: This 8LB density foam is extremely hard and rigid, like that of a soft wood. You fingernail can penetrate its skin, however it cannot be dented by hand.

16lb: This 16LB density foam is essentially as hard as a rock, you would need a hammer in order to make any dents in this product."

I'm guessing 3-4 cubic feet might be the volume of the rocker panels, rear strut area, and the under-seat rails. People seemed to report good results from the 2 lb foam so the 8 or 16 lb foams have got to be like having solid aluminum frame rails! I'd be willing to add 25-35 lbs of weight if it eliminates targa shimmy and the need for a heavy, unsightly targa brace.

I found some another good discussion on the subject at another forum: http://forums.maxima.org/showthread.php?t=444474

Check out the descriptions of the these densities:

"8lb: This 8LB density foam is extremely hard and rigid, like that of a soft wood. You fingernail can penetrate its skin, however it cannot be dented by hand.

16lb: This 16LB density foam is essentially as hard as a rock, you would need a hammer in order to make any dents in this product."

I'm guessing 3-4 cubic feet might be the volume of the rocker panels, rear strut area, and the under-seat rails. People seemed to report good results from the 2 lb foam so the 8 or 16 lb foams have got to be like having solid aluminum frame rails! I'd be willing to add 25-35 lbs of weight if it eliminates targa shimmy and the need for a heavy, unsightly targa brace.

I found some another good discussion on the subject at another forum: http://forums.maxima.org/showthread.php?t=444474

Last edited:

CTsupra

Supramania Contributor

They do this on Hondas from the factory, we see Honda clips all the time with foam inside the unibody frame rails.

Ok folks, I thought I'd give you an update on the whole foam injection attempt/project; So I have foam injected the sidesills and all three interior x members.

as well as all the underbody frame rails. Starting from the rear I left about 5-6 inches from the rear opening where the rear bumper hooks in, filled up the rear chassis x-member as well as the narrower vertical frame rails that go as far as the front seats area (now I know what Ian meant by saying that the underbody frame rails are of low volume).

And I also did the front frame rails right from where they begin under the front seats area upto the redline shown benieth

here's the pix

I can not really comment on the impact of this modification on the car yet as I still have a long way untill I get it back on the road but to be honest even then I don't think I'll be able to tell if the difference on the car's handling would be due to this mod as I have done a whole lotta things to my chassis apart from this.

The only fact that I can report is that it actually took me 19 cartridges of the 3M foam :aigo: so the expansion rate is definatelly not what 3M says, i.e.: 10x . I'd say that the expansion rate was more like 5x (entirely based on my personal judgement as I couldn't know what the actual inner volume of the frames that I injected is). The bad thing on this is of cource the financial part as these cost me almost $800 but I guess the good part is that the foam is much densier as it expanded less.

Oh well that's all really. I wish that this was done on a car that had it's suspension/chassis sorted already so that the results would be clearer as I honestly believe that this mod is the next best thing to a roll cage.

as well as all the underbody frame rails. Starting from the rear I left about 5-6 inches from the rear opening where the rear bumper hooks in, filled up the rear chassis x-member as well as the narrower vertical frame rails that go as far as the front seats area (now I know what Ian meant by saying that the underbody frame rails are of low volume).

And I also did the front frame rails right from where they begin under the front seats area upto the redline shown benieth

here's the pix

I can not really comment on the impact of this modification on the car yet as I still have a long way untill I get it back on the road but to be honest even then I don't think I'll be able to tell if the difference on the car's handling would be due to this mod as I have done a whole lotta things to my chassis apart from this.

The only fact that I can report is that it actually took me 19 cartridges of the 3M foam :aigo: so the expansion rate is definatelly not what 3M says, i.e.: 10x . I'd say that the expansion rate was more like 5x (entirely based on my personal judgement as I couldn't know what the actual inner volume of the frames that I injected is). The bad thing on this is of cource the financial part as these cost me almost $800 but I guess the good part is that the foam is much densier as it expanded less.

Oh well that's all really. I wish that this was done on a car that had it's suspension/chassis sorted already so that the results would be clearer as I honestly believe that this mod is the next best thing to a roll cage.