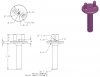

I am working on my senior design project, which is a simultaneous lug nut remover. I need a rough estimate of how much the parts would cost to make (labor, and material). The housing and cover could be aluminum. I would like the other 3 parts to be made of 1045 steel. :1zhelp:

rough cost estimate for machining

- Thread starter teamslow

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4U2QUIK

1UZFE SWAP DUDE!!!

I just happen to do routing and estimation at a machine shop.

I'll let you know tomarrow when I'm at work so I can get a good price on materials. But right off you're looking at least a few hundred dollars just in labor.

I'll let you know tomarrow when I'm at work so I can get a good price on materials. But right off you're looking at least a few hundred dollars just in labor.

4U2QUIK

1UZFE SWAP DUDE!!!

if its just a project, and its designed around taking off honda lugs, then i understand why hes doing it, especially if hes having to pay for this... 4 vs 5 of everything is a big cost difference.

sure would make life that much quicker when it came time to remove lugs, but you would need a DAMN good compressor or some really strong arms, but i guess you could jump on it with a wrench attached.

sure would make life that much quicker when it came time to remove lugs, but you would need a DAMN good compressor or some really strong arms, but i guess you could jump on it with a wrench attached.

Rennat;1194090 said:that looks pretty bad ass...

why not 5 lugs though?

yes. exactly what was stated above. i wanted to make it for a 5 lug but it would cost a lot more to make. it was also harder to get a good gear ratio to overcome the power loss to distribute torque to 5 other gears. i am using premade gears from mcmaster.com to reduce cost. so i could only work with the gears they have vs what will fit on a 4.5" bolt center diameter.

Clip;1194126 said:looks interesting, im not sure about badass though. how much torque will you need to run the thing?

well assuming the lug nuts are torqued to 100 ft lbs each, then a minimum of 320 ft lbs applied to the input shaft is required to loosen the lug nuts.

Last edited:

4U2QUIK;1194089 said:I just happen to do routing and estimation at a machine shop.

I'll let you know tomarrow when I'm at work so I can get a good price on materials. But right off you're looking at least a few hundred dollars just in labor.

can anyone give me a rough estimate of what a few hundred dollars would be?

4U2QUIK

1UZFE SWAP DUDE!!!

that's going to be one hell of an impact.

btw did you run a simulated stress test on the part? It looks like you need to beef up that main shaft a bit (depending on what material you use) I would guess this would run from $50-100 depending on what material will be used to fabricate this.

btw did you run a simulated stress test on the part? It looks like you need to beef up that main shaft a bit (depending on what material you use) I would guess this would run from $50-100 depending on what material will be used to fabricate this.

Kinda neat idea. Don't think it's going to work for lug removal, but it would be great for installation.

JASONA70;1195377 said:that's going to be one hell of an impact.

btw did you run a simulated stress test on the part? It looks like you need to beef up that main shaft a bit (depending on what material you use) I would guess this would run from $50-100 depending on what material will be used to fabricate this.

Yes. i did run an analysis on all the part. I ran all the part on ANSYS workbench. total deformation was all less then .001 in. i chose very conservative constraints. and the factor of safety for each part was all well above 1. The center shaft is made of 1045 steel. which has pretty high ultimate yield strength. I will try and post the results here later today because i have class in a few minutes and cant do it right now. I even have an animated video.

100 dollars seem a bit cheap for custom made parts. Tell me where they would do it for 100 dollars and i'll get my parts machined there.

suprarx7nut;1195384 said:Kinda neat idea. Don't think it's going to work for lug removal, but it would be great for installation.

well the input gear had 20 teeth and the output gears have 25 teeth. this gives a gear ratio of 1.25.

honda, acura's, toyota lug nuts are SUPPOSE to be torqued down to 80 foots lbs. for the sake of arguement, i chosen a value of 100 ft pounds for each lug nut. (100)(4)= 400 ft lbs. i took the gear ratio and took the inverse of the gear ratio to get the torque ratio. 400ftlbs/1.25=320ft lbs. A good impact gun can put out a maximum torque of 500ftlbs. only a minimum of 320 ft lbs is requied to lossen the lug nuts. Is my calculation wrong? i don't see why it wouldn't work to loosen the lug nuts. Yes i didnt account for friction. but the vibration of the pneumatic impact should help with that factor. The factor of safety for the teeth of the gear was around 2.9 which is really high.

Bring the question of doubts on!! so i can improve the design.:biglaugh:

Thanks,

Marc

4U2QUIK

1UZFE SWAP DUDE!!!

You'll probably want to change your input shaft to etd150 or stresspro0f if you plan on using an impact wrench. Otherwise it WILL twist in two.

4U2QUIK

1UZFE SWAP DUDE!!!

JASONA70;1195377 said:that's going to be one hell of an impact.

btw did you run a simulated stress test on the part? It looks like you need to beef up that main shaft a bit (depending on what material you use) I would guess this would run from $50-100 depending on what material will be used to fabricate this.

WTF did you get that price from?

Try closer to 300-500$

Just the body is going to cost that much because You need to purchase 9" round aluminum which is special order, and you have t0 buy 1 foot minumum. That's right around 200$ right there.

4U2QUIK

1UZFE SWAP DUDE!!!

ok cost for the housing alone is 56.49 for materials (this would be assuming we already have the material in stock, otherwise it would be around 200$ because you have to buy a foot minimum and it's special order.

Labor is around 150$

So just for the housing it would be 206$

Coverplate Would be about 20$ for materials, and about 110$ for labor

130$ total

Input shaft will be about 5$ for materials and around 70$ in labor

about75$ total

Btw on chamfers it's redundant to specify the chamfer diameter after specifying it's distance from the edge.

Output Shaft. I'd reccomend a redesign in order to save money.

if you mad some changes it could be done manually instead of a cnc which will be required because of your design.

But, it would be about 8$ in materials and about 125$ in labor.

133$ total for one and around 80$ a piece for four.

Same story with your lug design. it will cost a fraction of the price if you redisgn a couple of features.

They're going to run around 100$ a piece for one or around 60$ a piece for four.

For a grand total of. 971$ For one. The price would drop signifigantly for each additional one.

seem to me the guy who said 150$ likes to work for free. Considering material will be at least 100$!

BTW, all of the material quotes are as of today.

Labor is around 150$

So just for the housing it would be 206$

Coverplate Would be about 20$ for materials, and about 110$ for labor

130$ total

Input shaft will be about 5$ for materials and around 70$ in labor

about75$ total

Btw on chamfers it's redundant to specify the chamfer diameter after specifying it's distance from the edge.

Output Shaft. I'd reccomend a redesign in order to save money.

if you mad some changes it could be done manually instead of a cnc which will be required because of your design.

But, it would be about 8$ in materials and about 125$ in labor.

133$ total for one and around 80$ a piece for four.

Same story with your lug design. it will cost a fraction of the price if you redisgn a couple of features.

They're going to run around 100$ a piece for one or around 60$ a piece for four.

For a grand total of. 971$ For one. The price would drop signifigantly for each additional one.

seem to me the guy who said 150$ likes to work for free. Considering material will be at least 100$!

BTW, all of the material quotes are as of today.

An impact gun may not work in that system because of the slack. And if you really wanted to torque on those you would need something to support the whole machine or else it would just pop off when you try to torque the lugs. You would need like a leg, or a jack under it, if the lugs were tough. Its a cool design and all, but do you really have to get it built? It seems a bit impractical

Isphius;1195839 said:An impact gun may not work in that system because of the slack. And if you really wanted to torque on those you would need something to support the whole machine or else it would just pop off when you try to torque the lugs. You would need like a leg, or a jack under it, if the lugs were tough. Its a cool design and all, but do you really have to get it built? It seems a bit impractical

slack on what? What would pop off? There are magnets at the ends of the socket drives. support where? you hold the housing with your hand, the impact gun with your other hand. and the opposite side goes on the lug nuts to stay in place. no we weren't required to build it. but i wanted a cost estimate for the prototype to write in my report.

thanks 4U2QUIK!