suprarich;1628426 said:Not as much as one might think Mike. Having thoughts maybe??

Ebay?? Jinky...I can only imagine what the sellers fee would be for that!! I have several motors here that I might build on spec to sell if I ever get caught up. Watch out for some of those JDM engines, they could be in bad shape to begin with. Rebuild your motor!

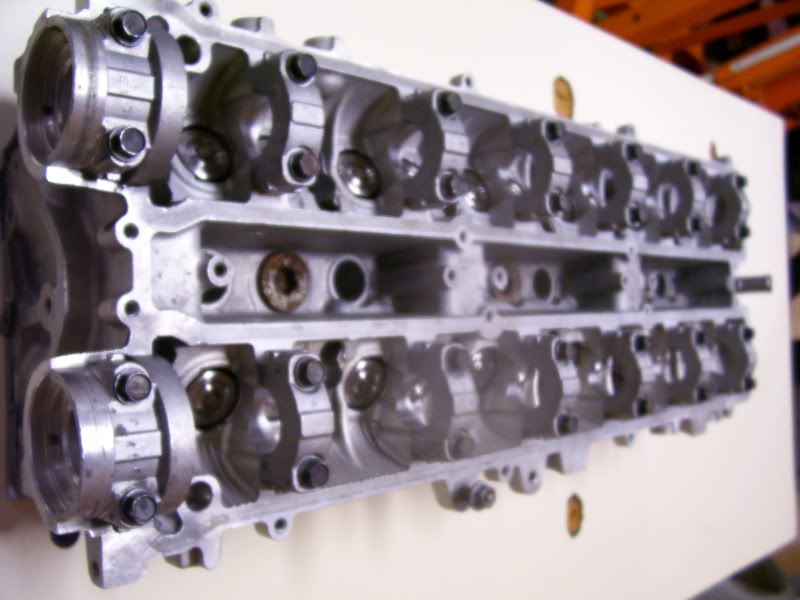

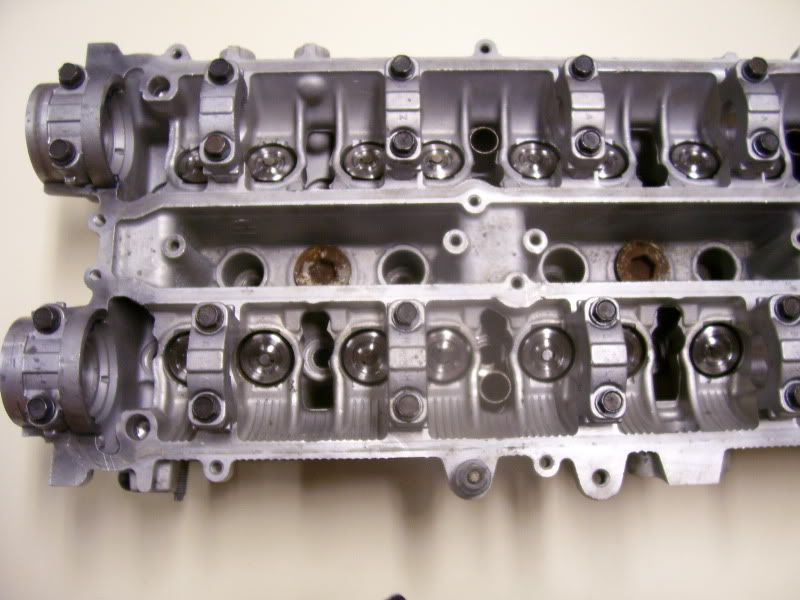

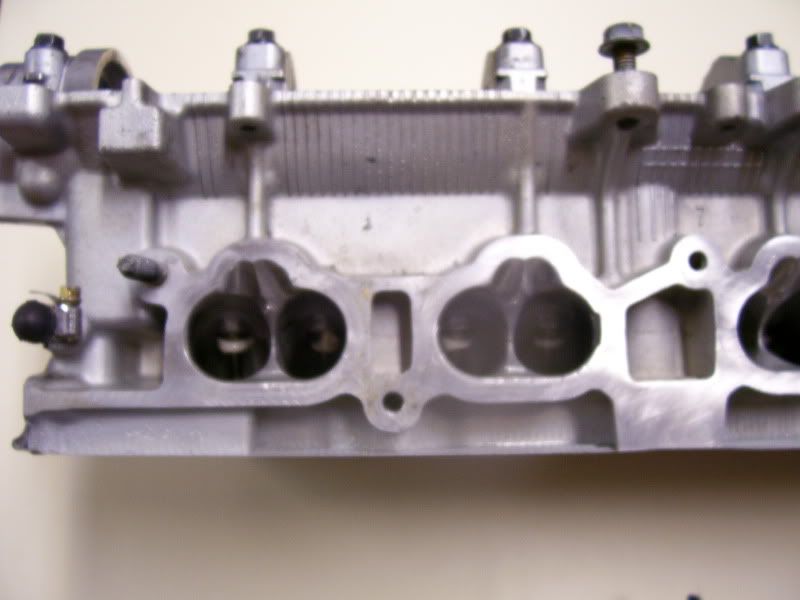

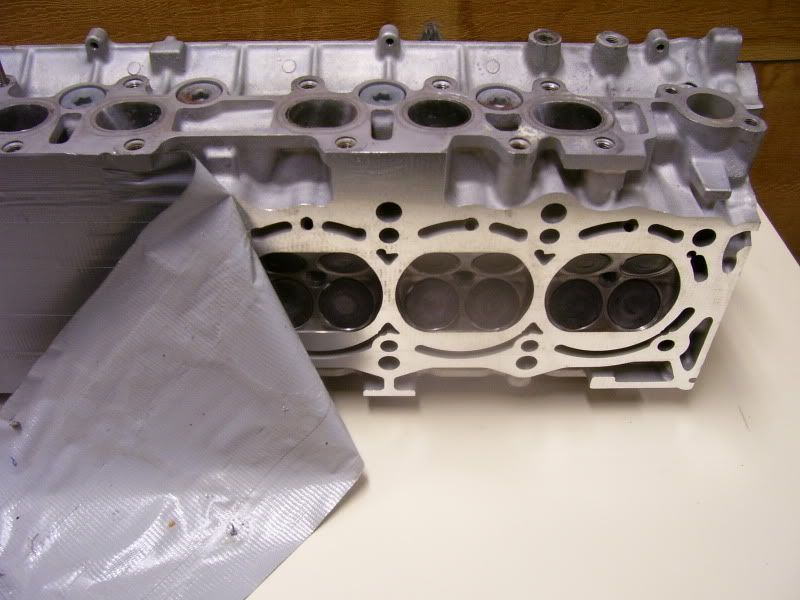

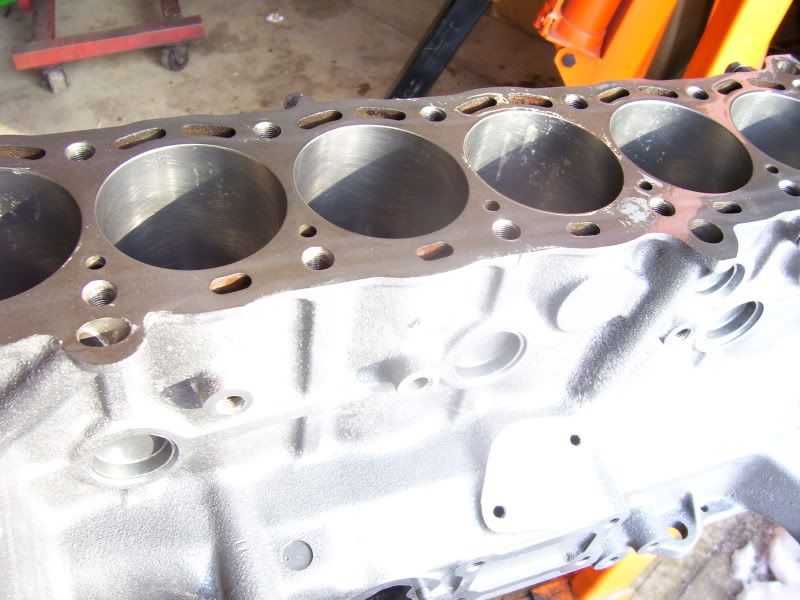

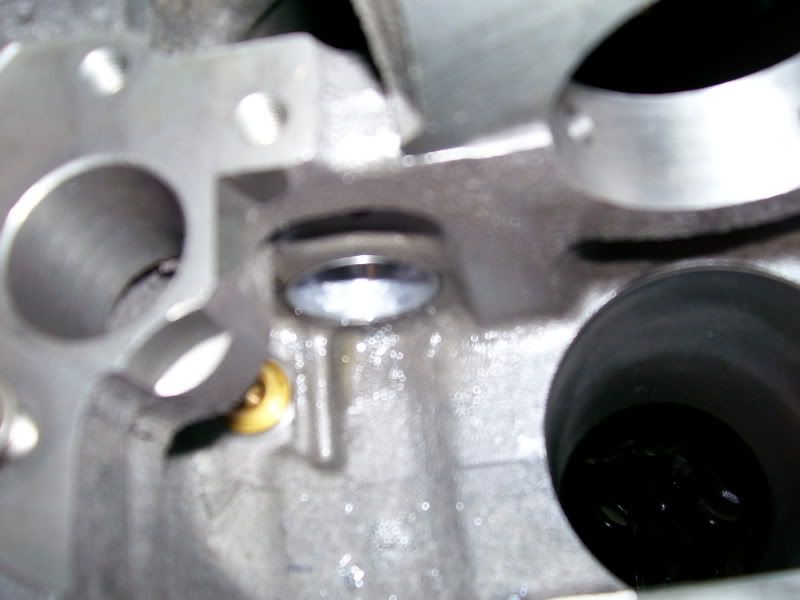

I just don't trust any machine shops around here, and I wanted to rebuild this motor. It's got crower rods, JE pistons, new oil pump, new water pump, etc.. that I'd like to transfer over. Would like new rings, bearings, proper piston to wall clearances to prevent slap. Etc. Since you clearly are a seasoned 7M vet. I'd like go thru you.

Mike