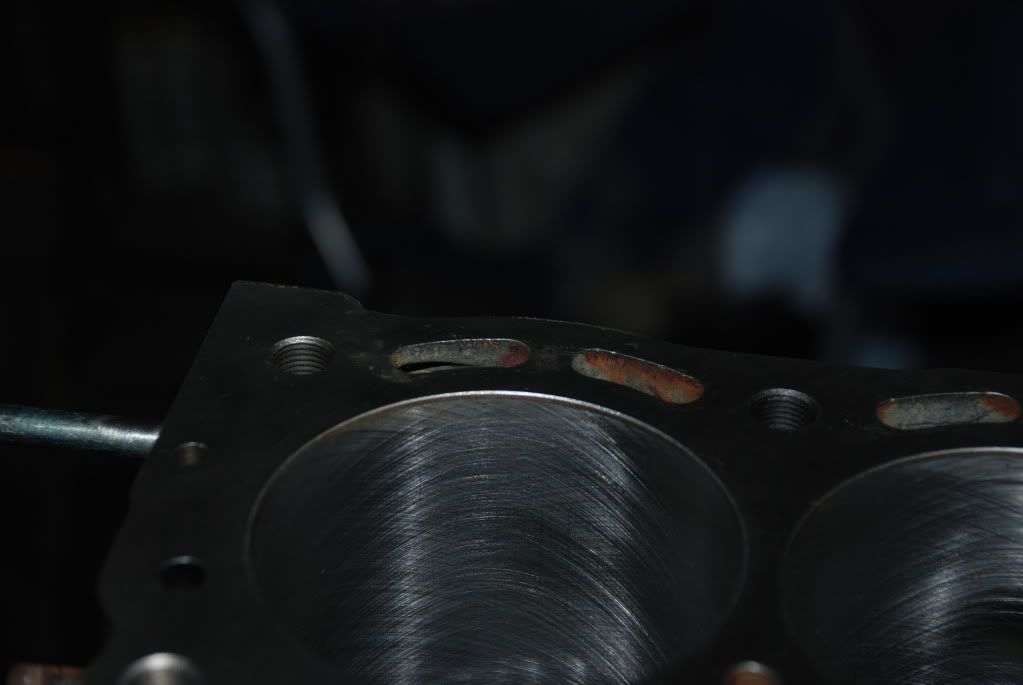

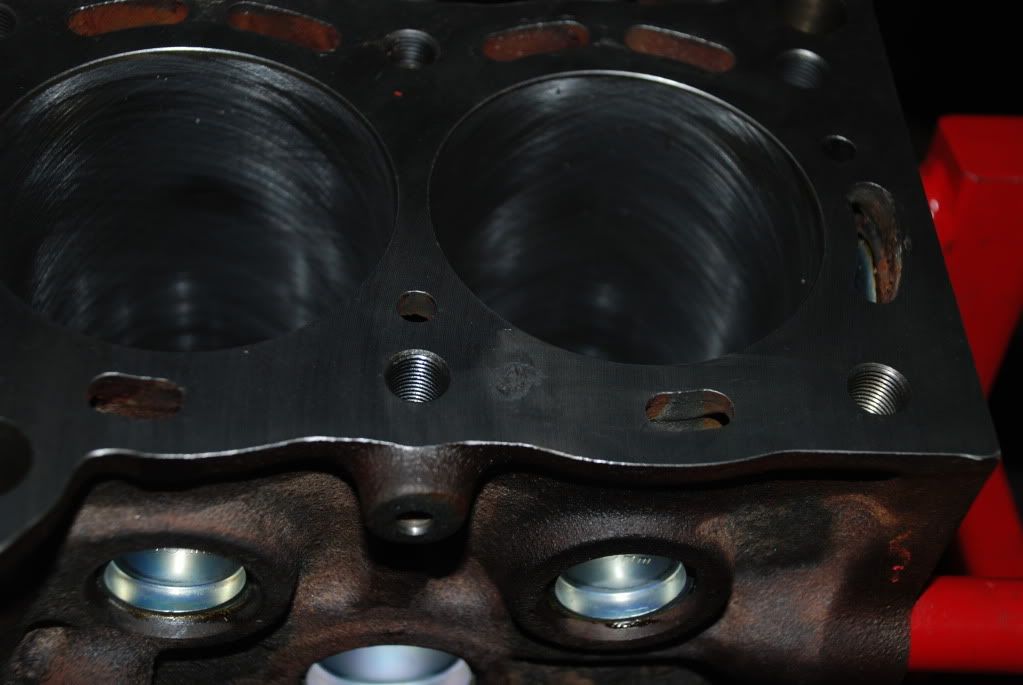

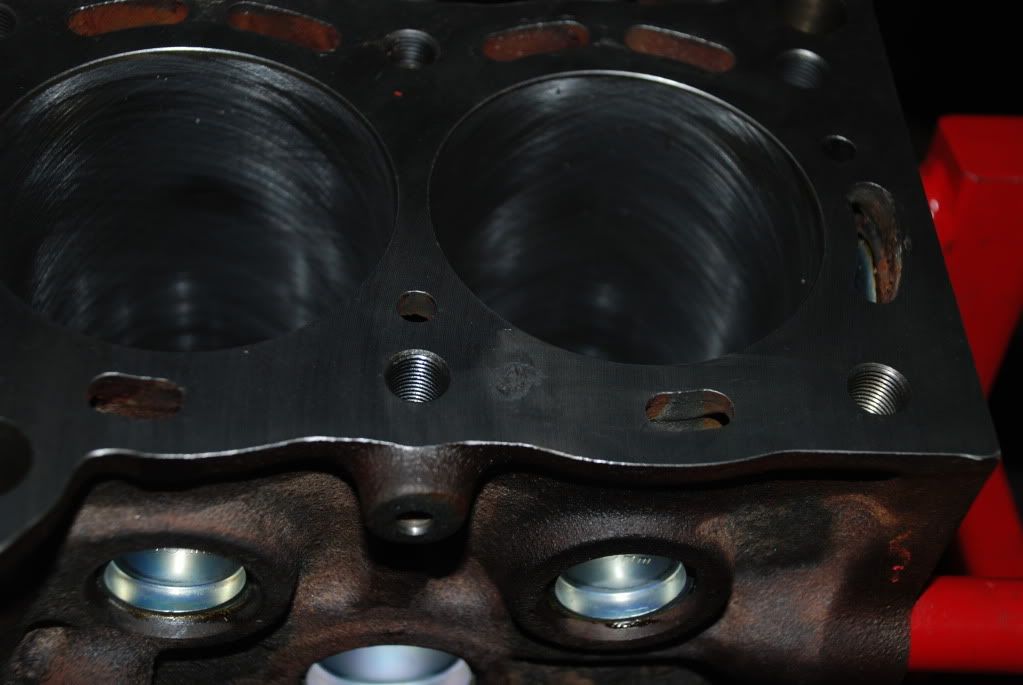

well, I just got my block back after waiting forever for the machine shop to finish. After getting it back, I saw all of these black "pockmarks" on the surface of the deck. All of them in areas where...I have no idea what happened. They did deck the block, but I don't know what is up with these small areas indented in the block.

The block was being prepped for a mhg, I told them it was a titan MLS gasket, and they said they'd take care of it (make sure it got the right RA), and they said they decked it 7/1000"

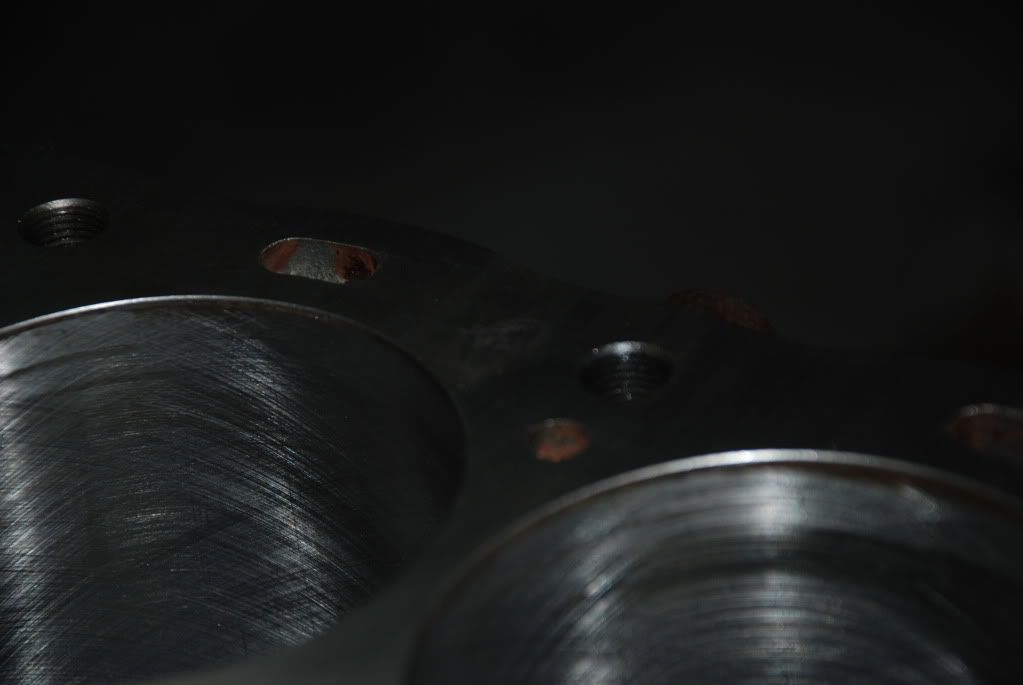

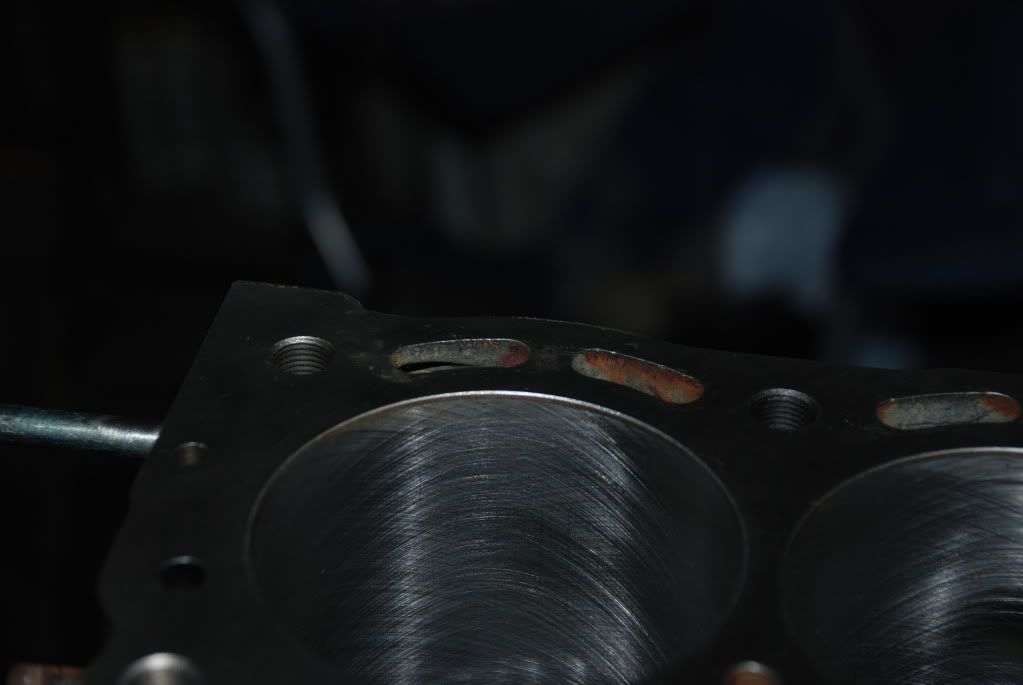

there are one or two 'big' pockmarked areas on the block, and around almost every cooling jacket, there appears to be small indents and pockmarks that indicate the block was excessively worn there or something.

this is my first rebuild guys, so please help me out here lol, I've been tried finding info on this on the internet but cant seem to find anything on it, so take a look:

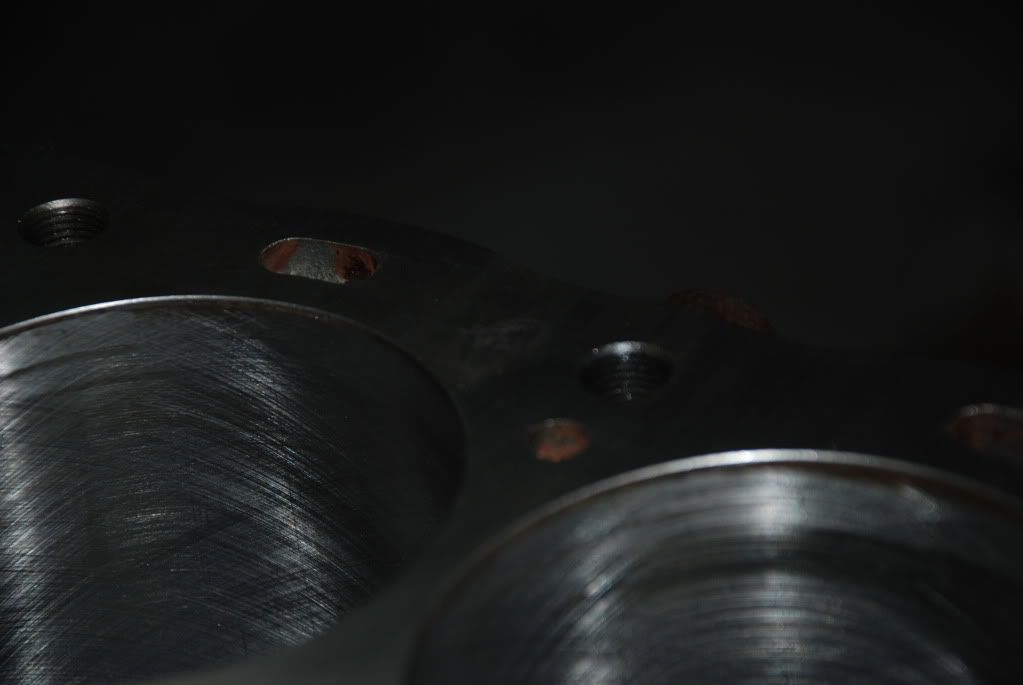

The flash seemed to really make the marks hard to see, but the last picture really shows them, around the farthest cooling jacket to the left-the black marks.

Is this normal? Should I worry, or am I good to go?

Thanks for the help guys.

edit: I can take any pictures you guy may desire, hopefully in the daylight tomorrow as well....

The block was being prepped for a mhg, I told them it was a titan MLS gasket, and they said they'd take care of it (make sure it got the right RA), and they said they decked it 7/1000"

there are one or two 'big' pockmarked areas on the block, and around almost every cooling jacket, there appears to be small indents and pockmarks that indicate the block was excessively worn there or something.

this is my first rebuild guys, so please help me out here lol, I've been tried finding info on this on the internet but cant seem to find anything on it, so take a look:

The flash seemed to really make the marks hard to see, but the last picture really shows them, around the farthest cooling jacket to the left-the black marks.

Is this normal? Should I worry, or am I good to go?

Thanks for the help guys.

edit: I can take any pictures you guy may desire, hopefully in the daylight tomorrow as well....