As for rod knock prevention

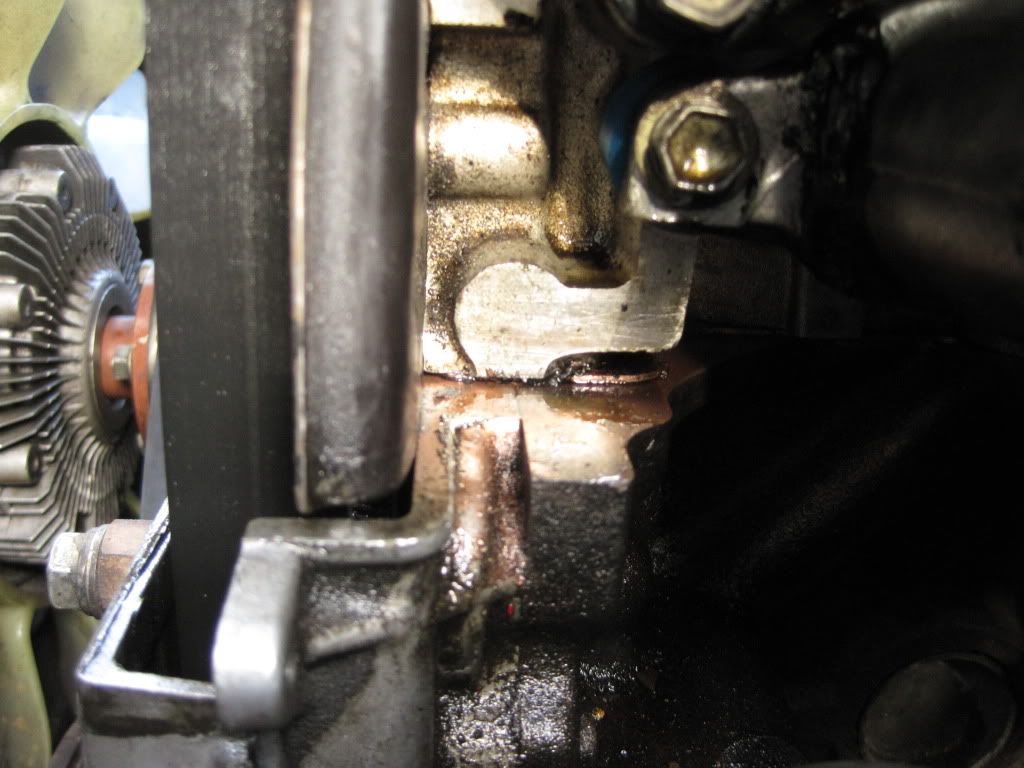

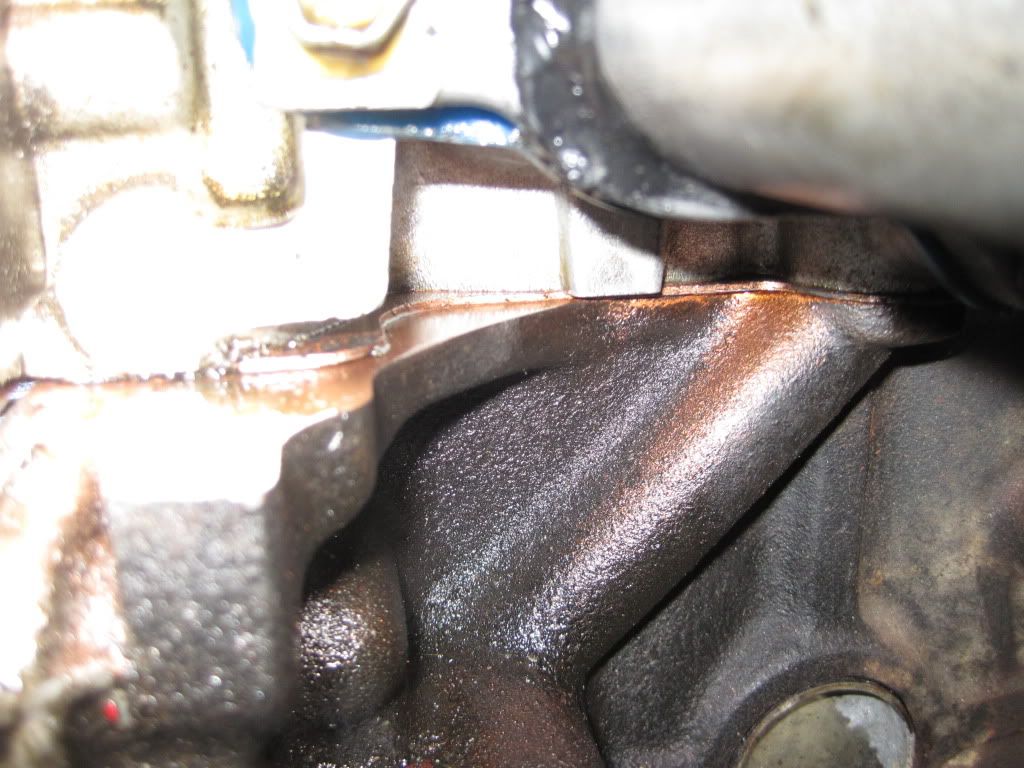

Take off the oil pan and wipe the shit clean make sure its dry and coolant free.

Take off the oil pan and wipe the shit clean make sure its dry and coolant free.

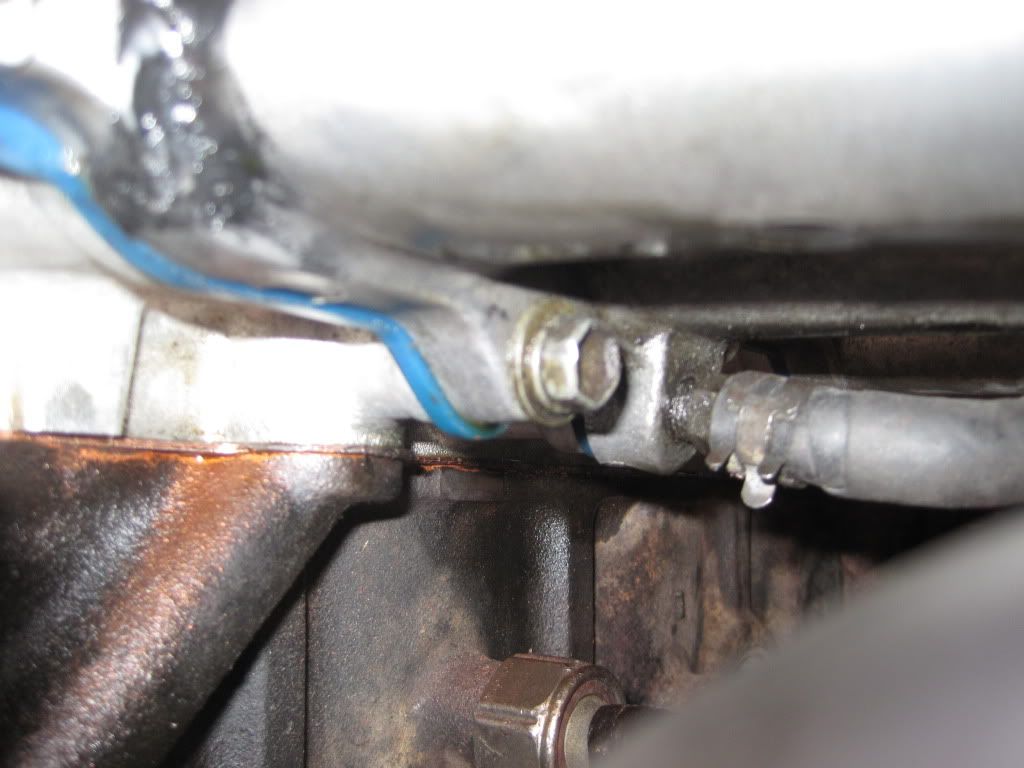

oldsking;1838546 said:And there goes the saying, "Yea a nice reliable 2JZ is what I need... What you need to do is properly install the head and not rush the job to make a drift event. Due to the poor installation you may have screwed your head up by warping it. All in all next time take your time and do the installation correctly and dont just go boosting while you are trying to seat the gasket! Its stories like this that make people say the 7m is bad but it all starts from the "mechanic" who worked on it.