would i be safe to use .5 MM oversized valves with out port and polishing the head? im not trying to do any thing hard core im leave it pstock im also put the comp cam springs in.would that be worth doing with out the P&P?

oversided valves/without p&p?

- Thread starter snyder250

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

a) why bother going .5 OS?

b) why bother going OS at all if you're not opening up the port to suit?

b) why bother going OS at all if you're not opening up the port to suit?

As IJ said, all that (really) is doing is putting a larger valve head for the air to get around. If you're not at least unshrouding the valves and doing a valve job, then you're doing nothing more than hanging a few more grams off your valve stem.

At a bare minimum the throats should be opened up the same amount and blended into the port walls, I don't get the whole haffassed concept of putting larger valves onto stock seats and expecting it to be an upgrade.... :nono:

suprahero;1471143 said:That's like windshield wipers on a billy goats ass.............it just won't work.

had me in tears Jay!

Adjuster

Supramania Contributor

It will not do anything of benefit in my view/opinion, but just curious where/what are the valves from?

Could be a good source for a cheap upgrade, BUT you would need to do as IJ mentioned, and have the valve seats/throat/Inside Diameter opened up at least .5mm as well. (Same as the Comp Cams BBC innner valve springs are a great cheap upgrade for any 7M head rebuild.)

I'm running 2mm OS valves, and the stock seats are cut to fit that size valve for both the angles, and to open up the seat ID. (This makes the stock sharp edges even worse, so you have to go down into the intake and exhaust runners and smooth them out by removing/tapering the areas cut while also not taking too much off to screw up the flow, or breaking through the runner into a coolant jacket.)

I think keeping it simple is best when porting. Think VENTURI or VOLUTE, where you start with a wider tapered opening, and then it gently tapers all the way to the slightly smaller opening at the other end. Basicly, air is a fluid, and it likes to flow around smooth radioused surfaces, and gentle curves if possible. Sharp corners, edges and casting flash all upset the flow, create turbulence, and thus create flow restrictions.

One word of advice on the EXHAUST side, you want to keep a 1mm sharp edge where the exhaust port goes from the head to the exhaust manifold. This is designed into the stock head, and it's there for a purpose. (Especially on the stock log type manifold.) The lip reduces exhaust gas reversion into the head. It creates a turbulent point that limits how much exhaust gas can go back towards the head, and promotes the gas to flow away from the head. (Think river that has a short set of falls, the water just rolls over it, and continues on, but does not go back up.. but if you have water flowing into a sharp edge like this, it kicks the water up, and creates all kinds of havoc and splashing etc. All wasted energy.) It has been proven by few people in the past, that on the 7M engine, if you port match the exhaust side, you LOSE tourqe, especially down at lower RPM where you need it.

Now, the trick on the exhaust side is to both port your exhaust runner so it has the 1mm sharp edge compared to the gasket, and then on your MANIFOLD, port the opening there compared to the gasket so the GASKET adds another lip, a step if you will, that has a 1 or 2mm opening behind it that is like a venturi with an area for the turbulence to roll around, and then slip down the exhaust port. Any gas coming back up the port will see the exhaust runner open up, and then have a large stepped ridge 360 degrees around the exhaust port. Not very likely that the gas will go up or into the exhaust port that way, and that BOOSTS your low and mid range tourqe while not creating a restriction that will hamper your top end power much if anything.

Make sure you leave enough manifold material to firmly clamp the gasket to the head and seal it up however. BTW, I've done this to a few stock cast iron manifolds, and it seems to work well. You can't really port the entire exhaust manifold, but you can remove many of the casting flaws, and improve flow in many ways, as well as enhance the anti-reversion effect. For example, on the manifold, you want to radious the sides facing the head, but enhance any sharp points on the other side to give the exhaust flow a point to jump off of. (Sort of like a wing on your decklid, or how race cars, and many of today's cars have a smooth radious at the front, and then sharp edges at the back, to enhance flow, and reduce drag.) I've ported the "bump" in the stock manifold that is between both sides, to both enhance the curve, and leave a sharp wing edge pointed at the turbo.

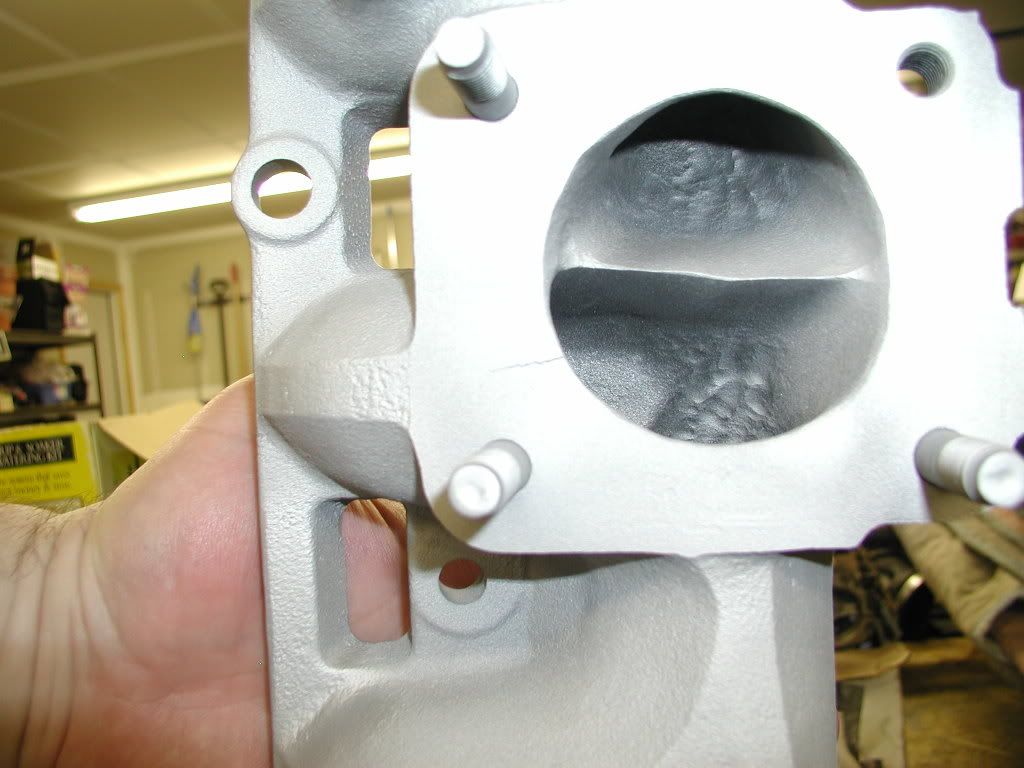

This is a coated, ported stock manifold I did. (This was when I had my bolt on T4 60-1.)

You can see the sharp, shaped edge, but what's harder to see is that I actually took quite a bit off to make that "TURN" smoother and more of a FLIP to send the exhaust pulse up and out of the manifold, v/s it trying to go across over to the other side of the opening. (You clearly want the exhaust to exit via the turbo right? LOL)

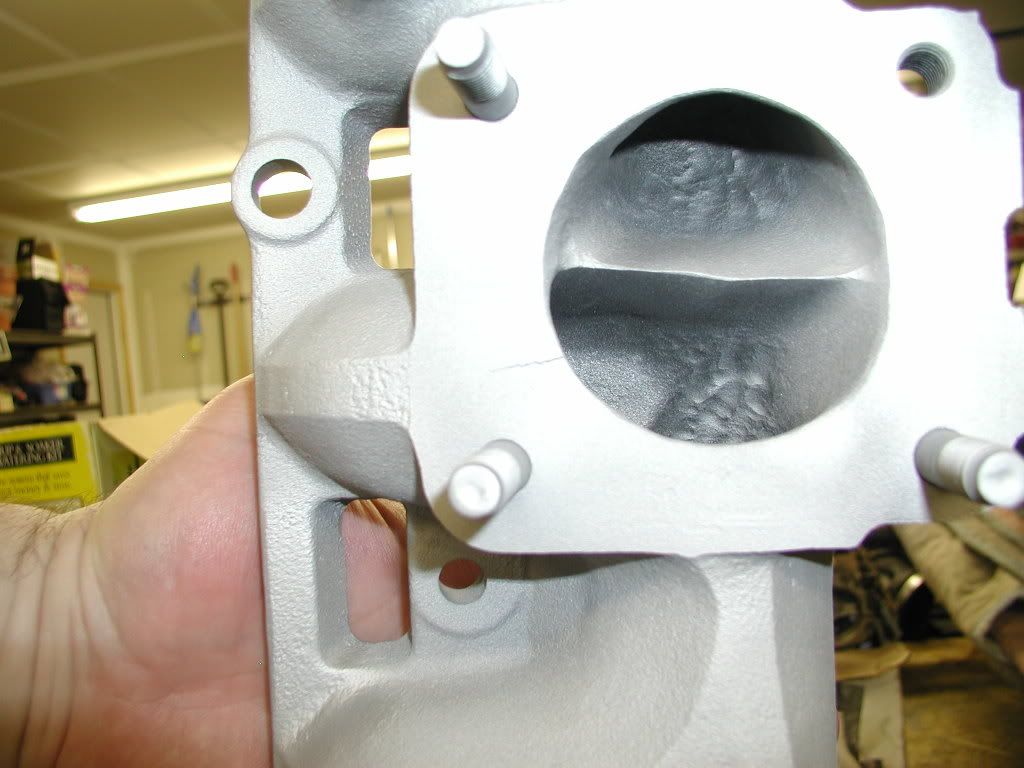

Here you can see how I've opened up, and smoothed the runners as much as possible.

At the point where the turbo is bolted to the manifold, you want to port/gasket match and then smooth the volute entrance to keep the flow as turbulence free as possible as it heads to the exhaust wheel.

The other side is just as important. Sure the exhaust gas is going to be turbulent as it exits the vanes, but you want to smooth it out, and let it out as much as possible, so I always smooth and match this are out, then coat them to control heat. The "golf ball" effect here was a side benefit of the cutter I was using. From this point back, my ports are all matched on the exhaust, and any bends are mandrel etc.

Look at aircraft, and then "create" that same idea, but in a rounded intake or exhaust port. What you don't want to do is have the seats cut, and then just leave that bigger sharp edge hanging out there in the flow to create a turbulent bubble of swirling gas.

I never took any pics of the head port work.. Sorry.

Now, I've talked to a few porting "masters" who think along various lines of thought. There is the camp that opening up the runer to max size with max size valves is best for peak power. (And I'd have to agree.)

Then there is the "Motoman" school of thought, that smoothing the intake runners in a volute that starts wide at the intake manifold, and then tapers down to a smaller inside diameter acclerates the air as it's going into the combustion chamber, and this boosts low and midrange power the most, and relies on the turbo's addition of boost pressure to overcome the loss in volume.

Basicly, with a turbo fed motor, you can have poor port designs, and still make decient power, but you can also gain the same advantages of any ported engine while still having the power added from forcing more air into the motor. (Best of both worlds.)

If you are going to add the valves, at least clean up the ports by smoothing the casting flash, and edges where the valve seats are cut etc. (Or just leave it stock, and turn up the boost.)

Good luck.

Could be a good source for a cheap upgrade, BUT you would need to do as IJ mentioned, and have the valve seats/throat/Inside Diameter opened up at least .5mm as well. (Same as the Comp Cams BBC innner valve springs are a great cheap upgrade for any 7M head rebuild.)

I'm running 2mm OS valves, and the stock seats are cut to fit that size valve for both the angles, and to open up the seat ID. (This makes the stock sharp edges even worse, so you have to go down into the intake and exhaust runners and smooth them out by removing/tapering the areas cut while also not taking too much off to screw up the flow, or breaking through the runner into a coolant jacket.)

I think keeping it simple is best when porting. Think VENTURI or VOLUTE, where you start with a wider tapered opening, and then it gently tapers all the way to the slightly smaller opening at the other end. Basicly, air is a fluid, and it likes to flow around smooth radioused surfaces, and gentle curves if possible. Sharp corners, edges and casting flash all upset the flow, create turbulence, and thus create flow restrictions.

One word of advice on the EXHAUST side, you want to keep a 1mm sharp edge where the exhaust port goes from the head to the exhaust manifold. This is designed into the stock head, and it's there for a purpose. (Especially on the stock log type manifold.) The lip reduces exhaust gas reversion into the head. It creates a turbulent point that limits how much exhaust gas can go back towards the head, and promotes the gas to flow away from the head. (Think river that has a short set of falls, the water just rolls over it, and continues on, but does not go back up.. but if you have water flowing into a sharp edge like this, it kicks the water up, and creates all kinds of havoc and splashing etc. All wasted energy.) It has been proven by few people in the past, that on the 7M engine, if you port match the exhaust side, you LOSE tourqe, especially down at lower RPM where you need it.

Now, the trick on the exhaust side is to both port your exhaust runner so it has the 1mm sharp edge compared to the gasket, and then on your MANIFOLD, port the opening there compared to the gasket so the GASKET adds another lip, a step if you will, that has a 1 or 2mm opening behind it that is like a venturi with an area for the turbulence to roll around, and then slip down the exhaust port. Any gas coming back up the port will see the exhaust runner open up, and then have a large stepped ridge 360 degrees around the exhaust port. Not very likely that the gas will go up or into the exhaust port that way, and that BOOSTS your low and mid range tourqe while not creating a restriction that will hamper your top end power much if anything.

Make sure you leave enough manifold material to firmly clamp the gasket to the head and seal it up however. BTW, I've done this to a few stock cast iron manifolds, and it seems to work well. You can't really port the entire exhaust manifold, but you can remove many of the casting flaws, and improve flow in many ways, as well as enhance the anti-reversion effect. For example, on the manifold, you want to radious the sides facing the head, but enhance any sharp points on the other side to give the exhaust flow a point to jump off of. (Sort of like a wing on your decklid, or how race cars, and many of today's cars have a smooth radious at the front, and then sharp edges at the back, to enhance flow, and reduce drag.) I've ported the "bump" in the stock manifold that is between both sides, to both enhance the curve, and leave a sharp wing edge pointed at the turbo.

This is a coated, ported stock manifold I did. (This was when I had my bolt on T4 60-1.)

You can see the sharp, shaped edge, but what's harder to see is that I actually took quite a bit off to make that "TURN" smoother and more of a FLIP to send the exhaust pulse up and out of the manifold, v/s it trying to go across over to the other side of the opening. (You clearly want the exhaust to exit via the turbo right? LOL)

Here you can see how I've opened up, and smoothed the runners as much as possible.

At the point where the turbo is bolted to the manifold, you want to port/gasket match and then smooth the volute entrance to keep the flow as turbulence free as possible as it heads to the exhaust wheel.

The other side is just as important. Sure the exhaust gas is going to be turbulent as it exits the vanes, but you want to smooth it out, and let it out as much as possible, so I always smooth and match this are out, then coat them to control heat. The "golf ball" effect here was a side benefit of the cutter I was using. From this point back, my ports are all matched on the exhaust, and any bends are mandrel etc.

Look at aircraft, and then "create" that same idea, but in a rounded intake or exhaust port. What you don't want to do is have the seats cut, and then just leave that bigger sharp edge hanging out there in the flow to create a turbulent bubble of swirling gas.

I never took any pics of the head port work.. Sorry.

Now, I've talked to a few porting "masters" who think along various lines of thought. There is the camp that opening up the runer to max size with max size valves is best for peak power. (And I'd have to agree.)

Then there is the "Motoman" school of thought, that smoothing the intake runners in a volute that starts wide at the intake manifold, and then tapers down to a smaller inside diameter acclerates the air as it's going into the combustion chamber, and this boosts low and midrange power the most, and relies on the turbo's addition of boost pressure to overcome the loss in volume.

Basicly, with a turbo fed motor, you can have poor port designs, and still make decient power, but you can also gain the same advantages of any ported engine while still having the power added from forcing more air into the motor. (Best of both worlds.)

If you are going to add the valves, at least clean up the ports by smoothing the casting flash, and edges where the valve seats are cut etc. (Or just leave it stock, and turn up the boost.)

Good luck.