Well I recently bought myself a daily driver, it is a 1987 Mazda B2000 with a 2.2L B2200 engine in it. Its a nice little truck and was what I could afford. It is a bit rough but it will get me around while I work on my real car (Supra). Anywho, the truck failed emissions. Here are the readings.

HC Reading - 2.95

HC Limit - 3.0

HC- Pass

CO Reading-81.24

CO Limit-25.00

CO-FAIL

Nox Reading-3.14

Nox Limit- 4.50

Nox-Pass

CO is obviously very high. HC is high, but still passing. I figure that the engine is overfueling. Here is my issue...

The truck has a computer controlled carburetor. I will start off by saying I know very little about carbs (I know how the work, but I have no practical experience working with them). Add on the fact that there is a computer in the mix along with about 2 miles of vacuum line and I am at a loss where to begin with this thing. From what I understand, the system uses the o2 sensor to adjust a/f ratio using an "A/F Ratio Solenoid" within the carb. The specifics of how it works, I am unsure, but there are several VSV's for different functions such as decell fuel cut off, choke etc.

I need help with one thing specifically. I am looking in the service manual and have come across checking the duty cycle of the a/f solenoid. By looking at this, I can supposedly determine if the truck is in open loop, commanding rich, commanding lean etc. They are asking me to use a dwell meter in the check connector in the engine bay, and measure the duty cycle of the solenoid. I'm a little confused here, I have never used a dwell meter before, and as far as I knew duty cycle was measured in % not degrees? I have attached the illustrations.

"

DWELL FIXED BELOW 20°(RICH COMMAND)

The ECU is signaling the mixture control solenoid to "go rich" (engine is idling lean). Try choking the carburetor by covering the air inlet with your hand, fingers slightly open. Gradually close the air gap between your fingers while watching the mixture control dwell. If the dwell increases, check for vacuum leaks at carburetor base and intake manifold. Check float level through sight glass and adjust if necessary. If no problems are found, proceed with idle mixture adjustment. If the dwell does not change while choking the carburetor, check the oxygen sensor and feedback system.

DWELL FIXED ABOVE 70°(LEAN COMMAND)

The ECU is signaling the mixture control solenoid to "go lean" (engine is idling rich or oxygen sensor is contaminated). Try creating a vacuum leak by removing the PCV valve and covering the hose with your thumb. Then gradually uncover the hose while watching the mixture control dwell. If dwell decreases, check for high float level or float bowl flooding (needle valve not shutting off fuel). Check evaporative system for liquid fuel saturation. If float level and evaporative system are OK, proceed with idle mixture adjustment. If dwell cannot be adjusted down, carburetor overhaul and possible mixture control solenoid replacement is indicated. If the dwell does not change when vacuum leak is created, check the oxygen sensor and feedback system.

DWELL FIXED AT 20°(FAIL-SAFE OPERATION)

Check for open oxygen sensor circuit or failed oxygen sensor."

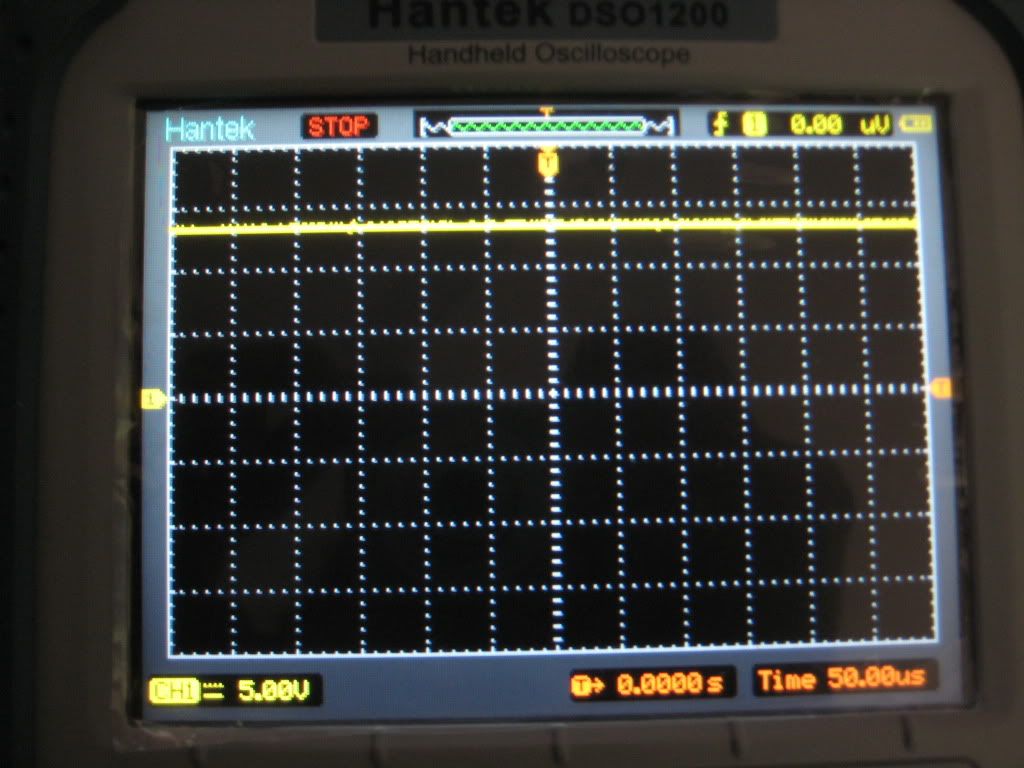

I checked it by setting my meter to 4 cyl dwell. With the engine idling it read about 80 fixed (keep in mind my dwell meter is digital), but the o2 sensor read about .3V. I want to make sure I am doing this test properly before I start trying to trace an open in the o2 circuit.

Things I have already checked include

Plugs- Plugs appear to be brand new

Choke- Working properly, opening fully when warm

Air filter- Appears to be brand new

Float level- Appears proper (level in the middle of the sight glass while idling)

A/F solenoid functionally tests good (clicks when grounded and idle speed changes when grounded while running)

Have not yet checked ignition timing, could incorrect timing cause high CO?

The engine appears to have an aftermarket MSD type ignition system, could this have anything to do with it?

The engine has the original cat (mounted to the manifold) hollowed out, but has a newer cat installed downstream of that.

Any help on this topic would be great, sorry this post is so lengthy.

HC Reading - 2.95

HC Limit - 3.0

HC- Pass

CO Reading-81.24

CO Limit-25.00

CO-FAIL

Nox Reading-3.14

Nox Limit- 4.50

Nox-Pass

CO is obviously very high. HC is high, but still passing. I figure that the engine is overfueling. Here is my issue...

The truck has a computer controlled carburetor. I will start off by saying I know very little about carbs (I know how the work, but I have no practical experience working with them). Add on the fact that there is a computer in the mix along with about 2 miles of vacuum line and I am at a loss where to begin with this thing. From what I understand, the system uses the o2 sensor to adjust a/f ratio using an "A/F Ratio Solenoid" within the carb. The specifics of how it works, I am unsure, but there are several VSV's for different functions such as decell fuel cut off, choke etc.

I need help with one thing specifically. I am looking in the service manual and have come across checking the duty cycle of the a/f solenoid. By looking at this, I can supposedly determine if the truck is in open loop, commanding rich, commanding lean etc. They are asking me to use a dwell meter in the check connector in the engine bay, and measure the duty cycle of the solenoid. I'm a little confused here, I have never used a dwell meter before, and as far as I knew duty cycle was measured in % not degrees? I have attached the illustrations.

"

- With engine already at normal operating temperature, start engine and run at 2,000 rpm for 1 minute, then let idle.

- Connect a dwellmeter to the A/F check connector (Br/Y wire). Set meter to 4 cyl. scale.

- Check the air/fuel solenoid duty cycle (dwell) at the specified rpm (800-850 rpm). Dwell should be in the inspection range and varying.

| 20°- 70° | � | |

| NOTE: | Adjustment of the idle mixture is normally unnecessary. If the duty cycle is not within specifications, perform the following quick check. |

The ECU is signaling the mixture control solenoid to "go rich" (engine is idling lean). Try choking the carburetor by covering the air inlet with your hand, fingers slightly open. Gradually close the air gap between your fingers while watching the mixture control dwell. If the dwell increases, check for vacuum leaks at carburetor base and intake manifold. Check float level through sight glass and adjust if necessary. If no problems are found, proceed with idle mixture adjustment. If the dwell does not change while choking the carburetor, check the oxygen sensor and feedback system.

DWELL FIXED ABOVE 70°(LEAN COMMAND)

The ECU is signaling the mixture control solenoid to "go lean" (engine is idling rich or oxygen sensor is contaminated). Try creating a vacuum leak by removing the PCV valve and covering the hose with your thumb. Then gradually uncover the hose while watching the mixture control dwell. If dwell decreases, check for high float level or float bowl flooding (needle valve not shutting off fuel). Check evaporative system for liquid fuel saturation. If float level and evaporative system are OK, proceed with idle mixture adjustment. If dwell cannot be adjusted down, carburetor overhaul and possible mixture control solenoid replacement is indicated. If the dwell does not change when vacuum leak is created, check the oxygen sensor and feedback system.

DWELL FIXED AT 20°(FAIL-SAFE OPERATION)

Check for open oxygen sensor circuit or failed oxygen sensor."

I checked it by setting my meter to 4 cyl dwell. With the engine idling it read about 80 fixed (keep in mind my dwell meter is digital), but the o2 sensor read about .3V. I want to make sure I am doing this test properly before I start trying to trace an open in the o2 circuit.

Things I have already checked include

Plugs- Plugs appear to be brand new

Choke- Working properly, opening fully when warm

Air filter- Appears to be brand new

Float level- Appears proper (level in the middle of the sight glass while idling)

A/F solenoid functionally tests good (clicks when grounded and idle speed changes when grounded while running)

Have not yet checked ignition timing, could incorrect timing cause high CO?

The engine appears to have an aftermarket MSD type ignition system, could this have anything to do with it?

The engine has the original cat (mounted to the manifold) hollowed out, but has a newer cat installed downstream of that.

Any help on this topic would be great, sorry this post is so lengthy.