Figured I would start a thread in here because I have pictures of my BHG change and figured I'd post them.

I'll start with my Supra history though.

My very first car was a 1988 N/A 5 Speed.

Drove it for about 2000 miles and it rod knocked.

Pulled the engine as a learning experience and parted it out, still have it (see pictures below) and miss it. Since it died I always wonder what would have happened if it lived, would've saved me a lot of money, and life experiences.

My Next car was a land rover discovery 1995, and I loved "The Rover"

I truly beat the hell out of this car, and replaced/serviced almost everything. I would've kept it forever but I found my dream supra (for the most part).

The supra that this gallery is on is a 1987 Turbo with every option offered that year. When I saw the ad for it at 1500 I really wanted it. Turbo/Targa/TEMS (but auto).

Florida Car, came up to new hampshire around 2000, and just sat.

The car needed a new turbo, had an ants nest somewhere in it, bees nest in the gas door, needed interior work, and had sat an entire New Hampshire winter. It had a BHG, but it was replaced with felpro and arp studs.

Driving it home it decided to shut off and sit on the side of the highway right as I got into Massachusetts. I had no idea what the issue was, it had no fuel pressure when I loosened the bolt on the fuel rail so I checked all electrical parts for that and nothing came up. Ended up towing it home the day I bought it.

Dropped the fuel tank and was ready to smack myself. The gas in the tank was about 8 or 9 years old (from 1999/2000) and had ruined the filter sock.

Drained fuel tank, Replaced the fuel pump, fuel filter, fuel sock, and put the tank back on with gas. Started up fine. Decided to die on the way to a gas station. Towed home. The temp gauge would rise with the tach so I checked grounds and the ground on the intake manifold was very loose. Fixed this and now had no power to ECU, checked fuse and found this to be very loose, so I tightened the fuse holder and put it back. Car started excellent.

My next fix was the turbo. Got a semi decent one and swapped it in, After doing the swap I have to say I truly hate the oil lines going to the turbo.

Drove for a while and the car began having problems with the maf. Replaced it with a MAFTPRO and AEM UEGO

and AEM UEGO

Alternator Dies, and I replaced with some egay one.

Drove for a while, installed Tokiko Struts, Eibach Springs, 3 inch exhaust, APEXI N1 Muffler, BIC DDP (recirculated)

Put on a HKS SSQV and K+N Filter and upped the boost a little with a Hallman Boost Controller

My Christmas Present from parents was new brakes, so I have all new calipers rotors, pads, etc. (installed by me)

SUMMARY:

AFTERMARKET:

Maft Pro

BIC DDP Rerouted

3 Inch Exhaust

Apexi N1 Exhaust

K&N Intake

Hallman Boost Controller

AEM UEGO wideband

HKS SSQV BOV

Tokiko Struts

Eibach Springs

HKS Turbo Timer

OEM SPEC REDONE:

Brake Rotors

Brake Calipers

Fuel Filters

Alternator

All Belts (not Timing)

Hoses

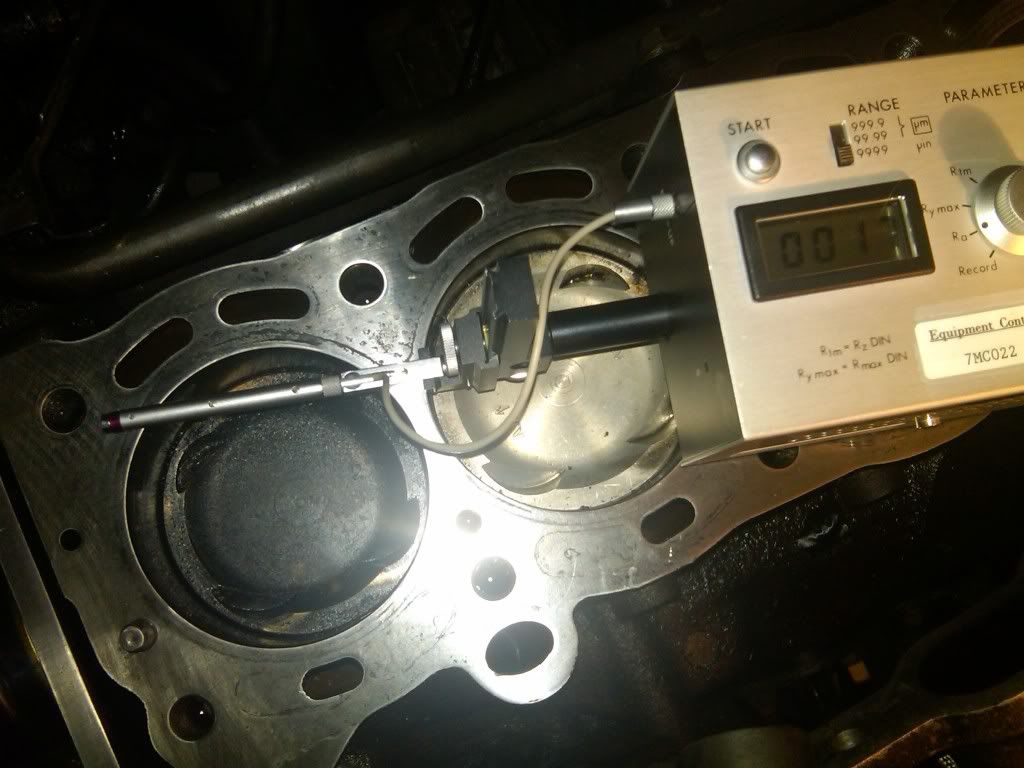

And then the radiator "pops" on the highway. I replace with a 5 speed radiator and separate tranny cooler, and have a great trail of smoke behind the car, and a complimentary milkshake in my oil cap

I'll start with my Supra history though.

My very first car was a 1988 N/A 5 Speed.

Drove it for about 2000 miles and it rod knocked.

Pulled the engine as a learning experience and parted it out, still have it (see pictures below) and miss it. Since it died I always wonder what would have happened if it lived, would've saved me a lot of money, and life experiences.

My Next car was a land rover discovery 1995, and I loved "The Rover"

I truly beat the hell out of this car, and replaced/serviced almost everything. I would've kept it forever but I found my dream supra (for the most part).

The supra that this gallery is on is a 1987 Turbo with every option offered that year. When I saw the ad for it at 1500 I really wanted it. Turbo/Targa/TEMS (but auto).

Florida Car, came up to new hampshire around 2000, and just sat.

The car needed a new turbo, had an ants nest somewhere in it, bees nest in the gas door, needed interior work, and had sat an entire New Hampshire winter. It had a BHG, but it was replaced with felpro and arp studs.

Driving it home it decided to shut off and sit on the side of the highway right as I got into Massachusetts. I had no idea what the issue was, it had no fuel pressure when I loosened the bolt on the fuel rail so I checked all electrical parts for that and nothing came up. Ended up towing it home the day I bought it.

Dropped the fuel tank and was ready to smack myself. The gas in the tank was about 8 or 9 years old (from 1999/2000) and had ruined the filter sock.

Drained fuel tank, Replaced the fuel pump, fuel filter, fuel sock, and put the tank back on with gas. Started up fine. Decided to die on the way to a gas station. Towed home. The temp gauge would rise with the tach so I checked grounds and the ground on the intake manifold was very loose. Fixed this and now had no power to ECU, checked fuse and found this to be very loose, so I tightened the fuse holder and put it back. Car started excellent.

My next fix was the turbo. Got a semi decent one and swapped it in, After doing the swap I have to say I truly hate the oil lines going to the turbo.

Drove for a while and the car began having problems with the maf. Replaced it with a MAFTPRO

Alternator Dies, and I replaced with some egay one.

Drove for a while, installed Tokiko Struts, Eibach Springs, 3 inch exhaust, APEXI N1 Muffler, BIC DDP (recirculated)

Put on a HKS SSQV and K+N Filter and upped the boost a little with a Hallman Boost Controller

My Christmas Present from parents was new brakes, so I have all new calipers rotors, pads, etc. (installed by me)

SUMMARY:

AFTERMARKET:

Maft Pro

BIC DDP Rerouted

3 Inch Exhaust

Apexi N1 Exhaust

K&N Intake

Hallman Boost Controller

AEM UEGO wideband

HKS SSQV BOV

Tokiko Struts

Eibach Springs

HKS Turbo Timer

OEM SPEC REDONE:

Brake Rotors

Brake Calipers

Fuel Filters

Alternator

All Belts (not Timing)

Hoses

And then the radiator "pops" on the highway. I replace with a 5 speed radiator and separate tranny cooler, and have a great trail of smoke behind the car, and a complimentary milkshake in my oil cap