First of all, all information provided in this thread comes from my personal experience with the 7m and other various engines i have worked with in my life. All the tricks, custom mods and all the assumptions i'll make are for ME, the best way to properly rebuild a 7m engine. I don't expect everyone to agree with me but please don't just discredit what I will say because you've read something else on the internet. Instead try to think twice before questioning and try to properly understand my point of view because i'm sure it will make sense.

let's talk a little bit about the project goals...

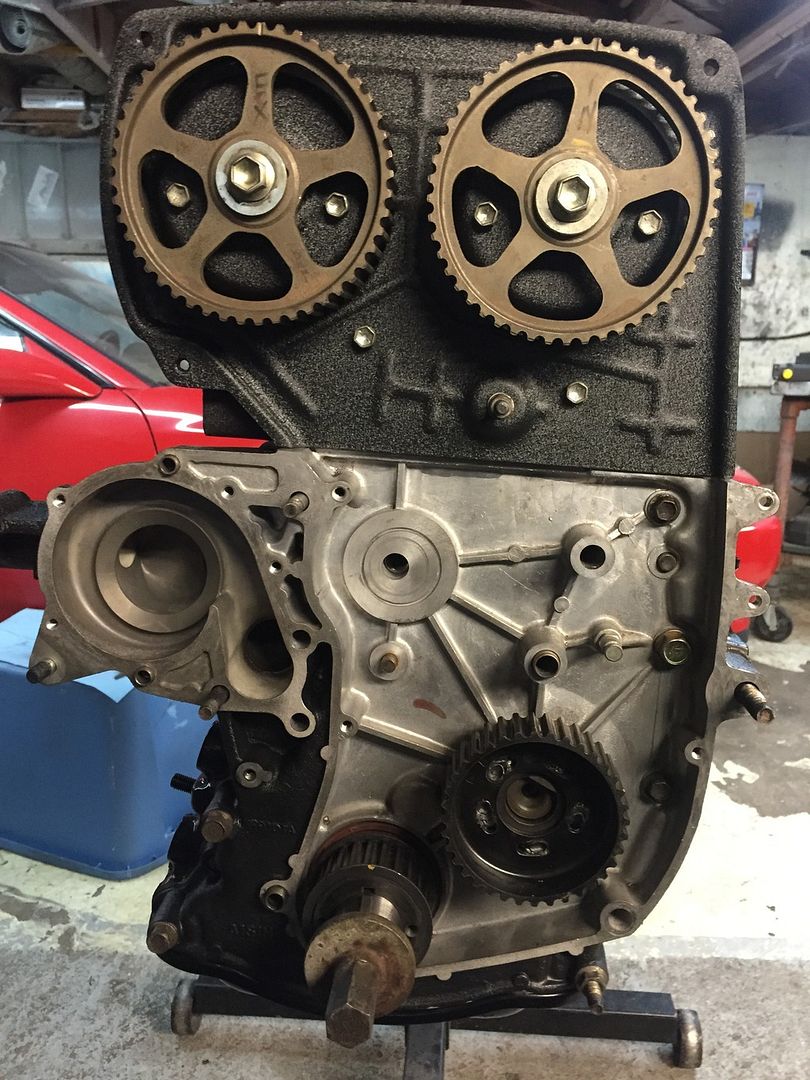

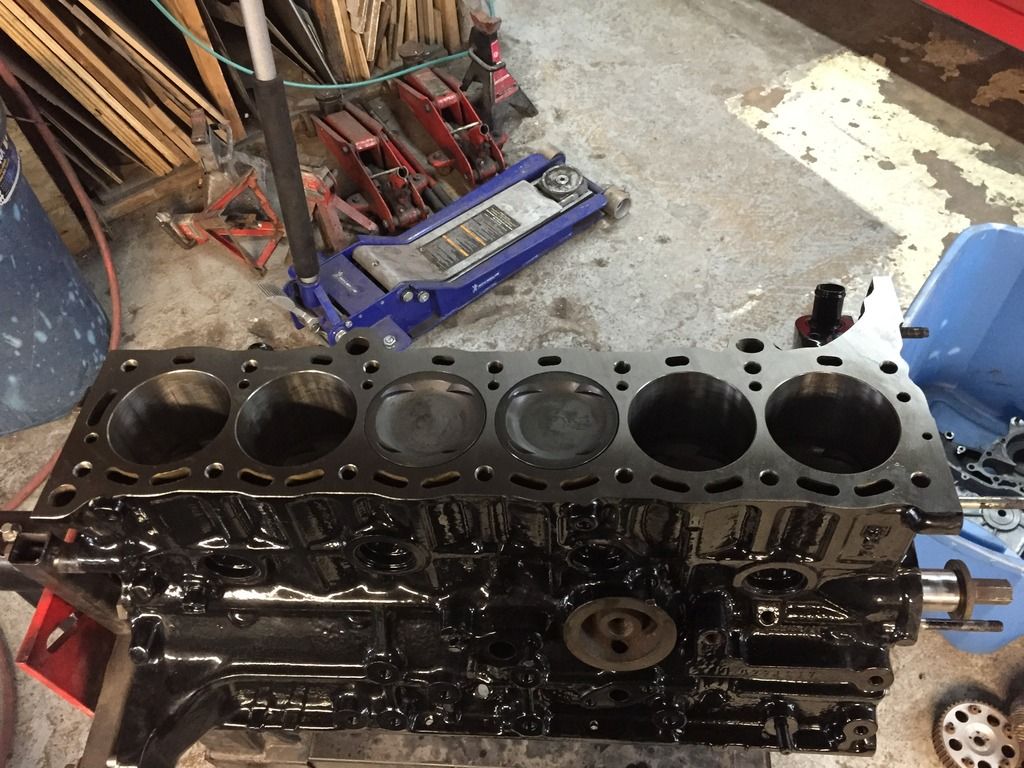

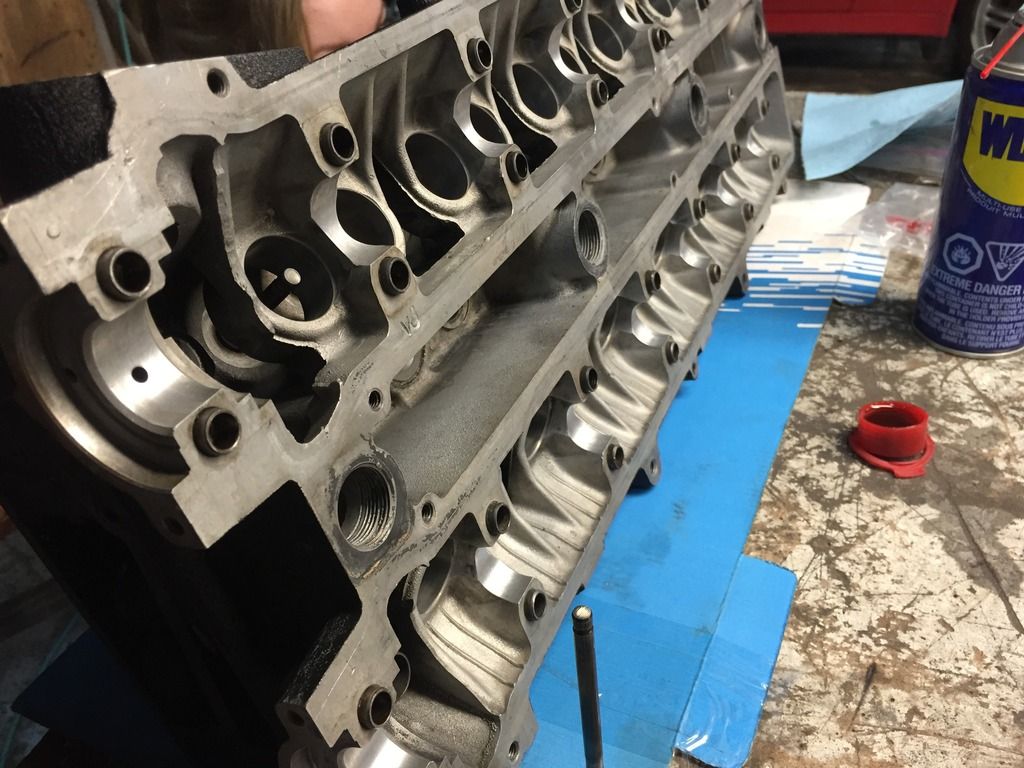

I am rebuilding this engine to put it in my girlfriend supra since she spun a bearing past novembre a week before putting the car away for winter. The engine had a 57trim CT26 installed with a lexus AFM and was boosting 18psi on the stock ECU with an SAFC; well pretty much the worse setup to have if you like your car running instead of broken. The new engine will be rebuilt using 99% stock components (except valve springs) and it should develop around 550-575whp as it is the max output of the turbo i'll use on it (EFR7670). (This turbo was on my 1JZ vvti MK3 last summer and dynoed 577whp with it so this is why I know what will be the output of the motor). I decided to rebuild the 7m instead of swaping a jz because I strongly believe that is is a lot more cost effective to do so.

Where to start when modding a 7m..

Even for just upping the boost the first mod to do is to put a PROPER engine management unit. it can be an AEM V1, V2, infinity, pro efi, MS3 MS3pro(this is what i use)...obviously the EMS need to be tuned by a competent tuner to ensure that it will be reliable. Even for the slight mods you still NEED an EMS if you care about your engine. Piggybacks will work for sure but it WILL eventually fail.. My .02 here is if you don't have money to install an EMS, why not just forget about having a modded supra. Most of the time 7m's fail because of the owner, and it happens more often than the famous 2jz because everyone who can't afford a jz or an MK4 end up with a 7mgte MK3 and as they have no money and they want 1000hp, they make stupid upgrades and bandaids to make there car fast, or at least, fast for the time it will work.

Now let's talk about the engine itself. I think i don't even have to mention anything about the head gasket problems of the 7m. Let just say that a proper MLS with studs will cure the problem forever if done properly. The stock internals of the engine DON'T need to be replaced for any setup on pump as it is impossible to put down enough trq on pump to bend a rod a a properly tuned setup. It is the same for the pistons, if detonation is kept away and the tune is spot on they will never fail on you on sub 650-700whp power levels. Many have done a rebuild and preferred to replace the rods and pistons instead of spending there money at the machine shop for a properly clearanced engine. This is not the way to do it!!!!!!

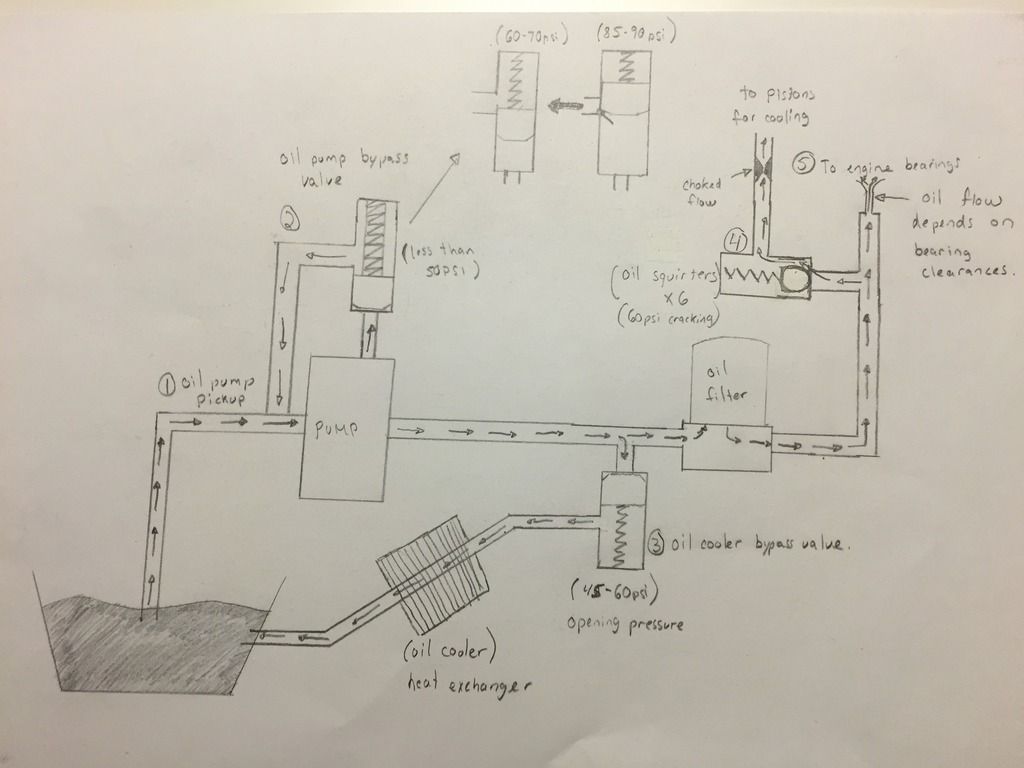

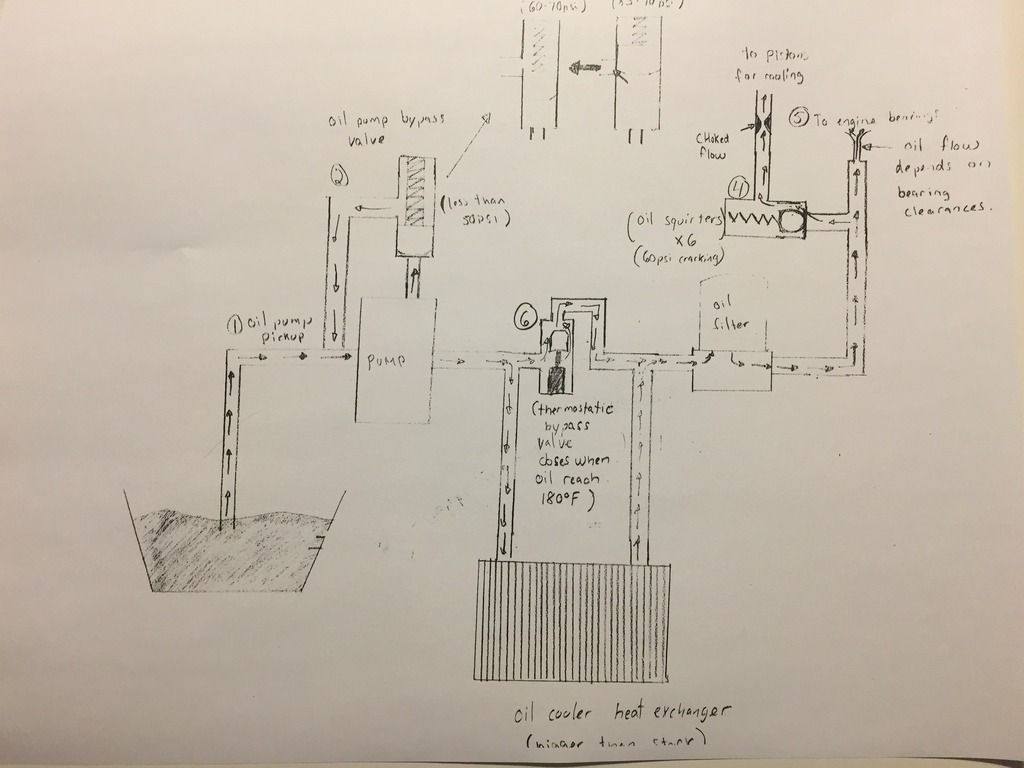

The WORST thing about the 7m is the OILING SYSTEM. Take care of it by modifying it the way it should and it will put the average 7m beside the 2jz as far as 500whp level reliability.. that 's what ill discuss in my next post...

FOR more info about all my projects, like my FB page

https://www.facebook.com/KMPsystems

let's talk a little bit about the project goals...

I am rebuilding this engine to put it in my girlfriend supra since she spun a bearing past novembre a week before putting the car away for winter. The engine had a 57trim CT26 installed with a lexus AFM and was boosting 18psi on the stock ECU with an SAFC; well pretty much the worse setup to have if you like your car running instead of broken. The new engine will be rebuilt using 99% stock components (except valve springs) and it should develop around 550-575whp as it is the max output of the turbo i'll use on it (EFR7670). (This turbo was on my 1JZ vvti MK3 last summer and dynoed 577whp with it so this is why I know what will be the output of the motor). I decided to rebuild the 7m instead of swaping a jz because I strongly believe that is is a lot more cost effective to do so.

Where to start when modding a 7m..

Even for just upping the boost the first mod to do is to put a PROPER engine management unit. it can be an AEM V1, V2, infinity, pro efi, MS3 MS3pro(this is what i use)...obviously the EMS need to be tuned by a competent tuner to ensure that it will be reliable. Even for the slight mods you still NEED an EMS if you care about your engine. Piggybacks will work for sure but it WILL eventually fail.. My .02 here is if you don't have money to install an EMS, why not just forget about having a modded supra. Most of the time 7m's fail because of the owner, and it happens more often than the famous 2jz because everyone who can't afford a jz or an MK4 end up with a 7mgte MK3 and as they have no money and they want 1000hp, they make stupid upgrades and bandaids to make there car fast, or at least, fast for the time it will work.

Now let's talk about the engine itself. I think i don't even have to mention anything about the head gasket problems of the 7m. Let just say that a proper MLS with studs will cure the problem forever if done properly. The stock internals of the engine DON'T need to be replaced for any setup on pump as it is impossible to put down enough trq on pump to bend a rod a a properly tuned setup. It is the same for the pistons, if detonation is kept away and the tune is spot on they will never fail on you on sub 650-700whp power levels. Many have done a rebuild and preferred to replace the rods and pistons instead of spending there money at the machine shop for a properly clearanced engine. This is not the way to do it!!!!!!

The WORST thing about the 7m is the OILING SYSTEM. Take care of it by modifying it the way it should and it will put the average 7m beside the 2jz as far as 500whp level reliability.. that 's what ill discuss in my next post...

FOR more info about all my projects, like my FB page

https://www.facebook.com/KMPsystems

Last edited: