Just done quite a lot of work on this for my university dissertation. Designed and built a carbon fibre inlet manifold for a formula sae car and designed (but didn't have time to build) a linear stepper motor controlled telescopic inlet primary system which took a signal from the crank sensor and via a pic PLC controller, sent the appropriate pipe height to the motor which would adjust very fast indeed.

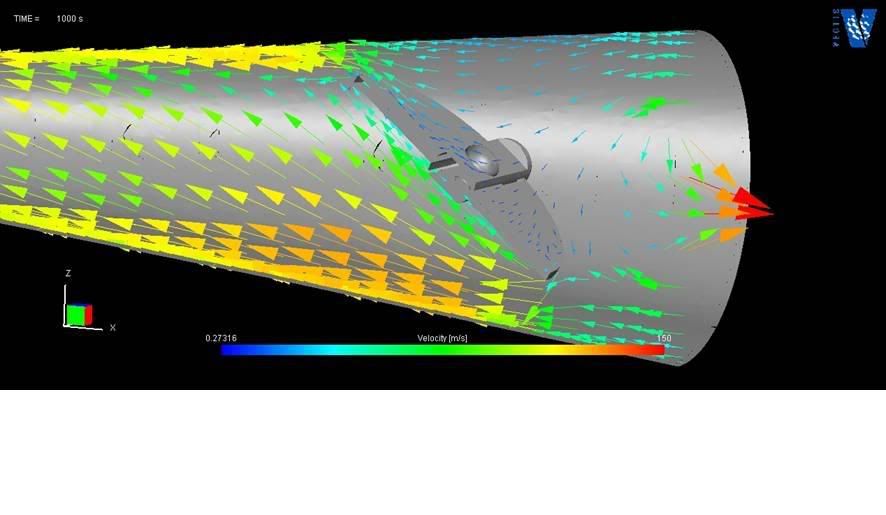

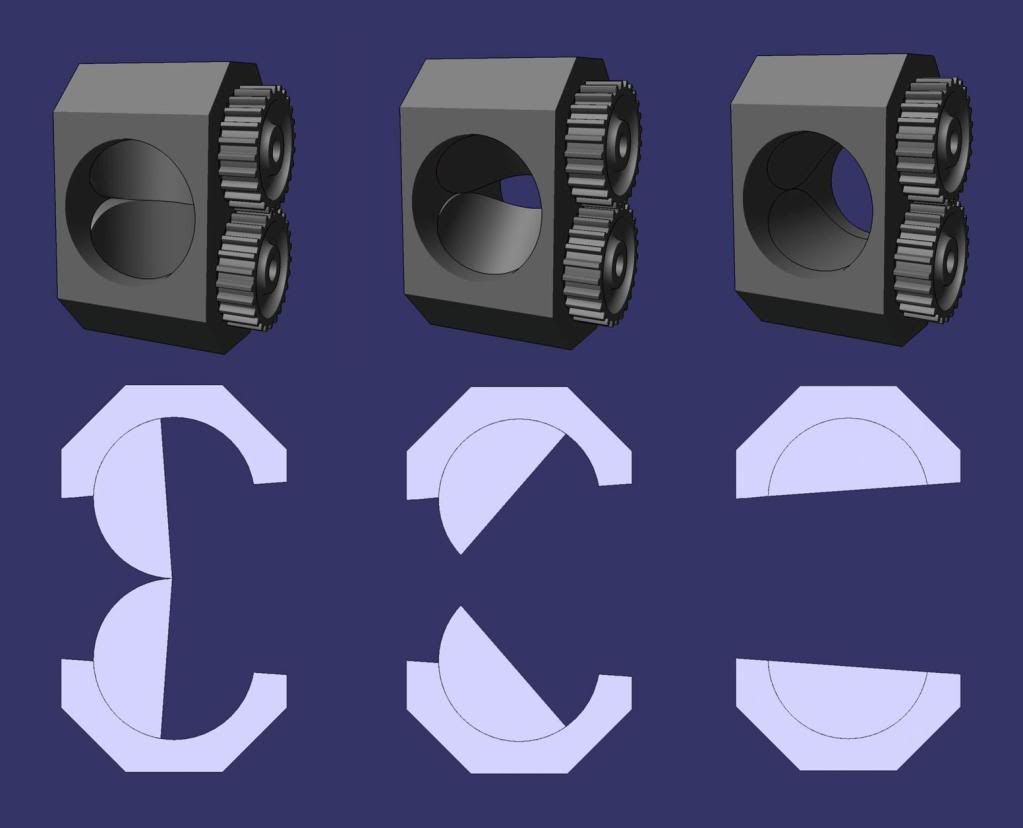

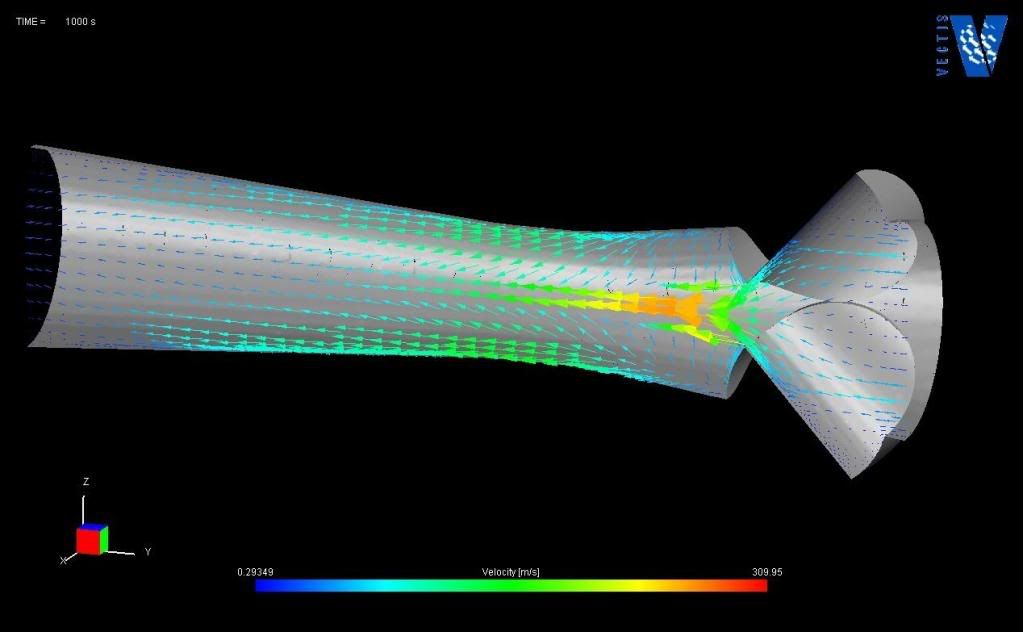

Anyhoo, as part of my research, I did a lot of work into throttle design and flow characteristics and I can safely say that a dual roller barrel system provides optimum flow. Camera shutter types cause some weird vorticies and are difficult to make strong enough, and butterflies create turbulance in the inlet...

What you want is something like this:

Following that, you want to get hold of a copy of this book:

http://www.amazon.co.uk/Theory-Engi...=sr_1_1?ie=UTF8&s=books&qid=1242417460&sr=8-1

And this book:

http://www.amazon.co.uk/INTERNAL-CO...=sr_1_2?ie=UTF8&s=books&qid=1242417569&sr=1-2

Ok they are a little pricey, but I'm sure you can get them somewhere cheaper on the net! I had to use the uni library copies... Both have some very good info on intake manifold design and theory though including variable length systems, exhaust gas recovery, dual plenum designs with balance valves, acoustic ramming, helmholtz resonators and all sorts... Interesting reading!