Hi all, Just after some advise on my head gasket please

I bought the car with the intention to change it as not knowing the history of the car and the fact they have the problem.

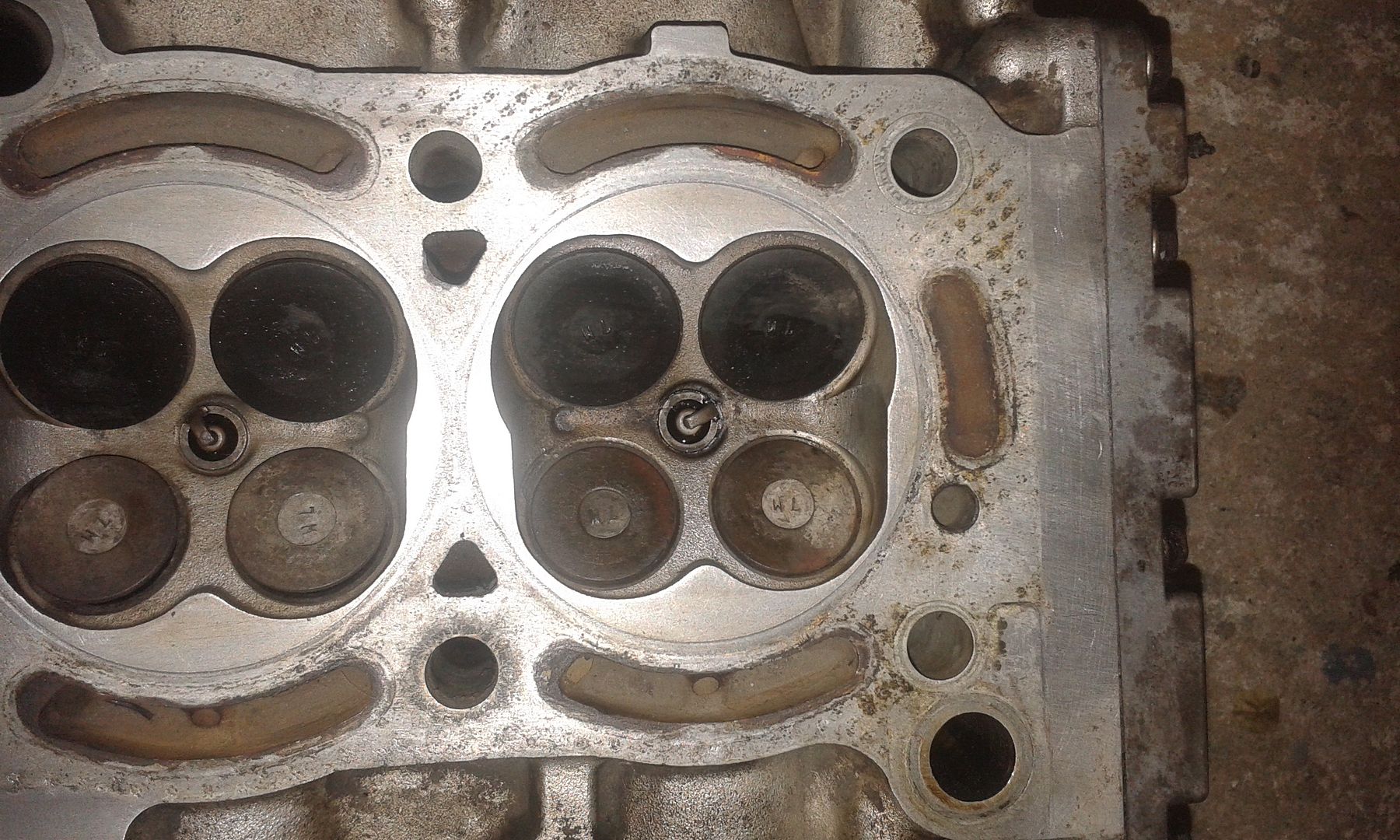

There were a few symptoms like the bubbling being the dash, using coolant which was escaping through the exhaust and high coolant pressure, number 6 was on 140 all the rest was around the 170-180, and a slight misfire. So I checked the head bolts for torque and it seems they were all around 80 ftlb apart from the 4 bolts around number 6 which was around the 60ftlbs, so with a re torque it did nothing, so stripped the head off and found the gasket not to be that bad. only thing I can see that would cause problems is the coolant parts are a bit messy and the cylinder was blowing between 5 -6 which was a surprise but would probably cause the misfire.

Cleaned the head, there is a slight bow to it which is obviously worse between 3 and 4, but from what ive been told that they do tend to have a slight bow being such a long head and being alloy that is should be fine when torqued down, I have a standard head gasket, not Toyota and arp head bolts and torque it down to 80-90 ftlb

I am after a few opinions first as what to do first from some supra owners first hand experiences

Many Thanks

I bought the car with the intention to change it as not knowing the history of the car and the fact they have the problem.

There were a few symptoms like the bubbling being the dash, using coolant which was escaping through the exhaust and high coolant pressure, number 6 was on 140 all the rest was around the 170-180, and a slight misfire. So I checked the head bolts for torque and it seems they were all around 80 ftlb apart from the 4 bolts around number 6 which was around the 60ftlbs, so with a re torque it did nothing, so stripped the head off and found the gasket not to be that bad. only thing I can see that would cause problems is the coolant parts are a bit messy and the cylinder was blowing between 5 -6 which was a surprise but would probably cause the misfire.

Cleaned the head, there is a slight bow to it which is obviously worse between 3 and 4, but from what ive been told that they do tend to have a slight bow being such a long head and being alloy that is should be fine when torqued down, I have a standard head gasket, not Toyota and arp head bolts and torque it down to 80-90 ftlb

I am after a few opinions first as what to do first from some supra owners first hand experiences

Many Thanks