To all who have experience with this or work with bottom ends FREQUENTLY:

I took my motor apart last week and have had my crank sitting in my block since, no main caps.

A friend came over tonight and I rotated my stand (!!!) forgetting the crank was just resting, and it fell. It fell about two feet to my garage floor. None of the journal surfaces touched, aside from the rear main seal surface.

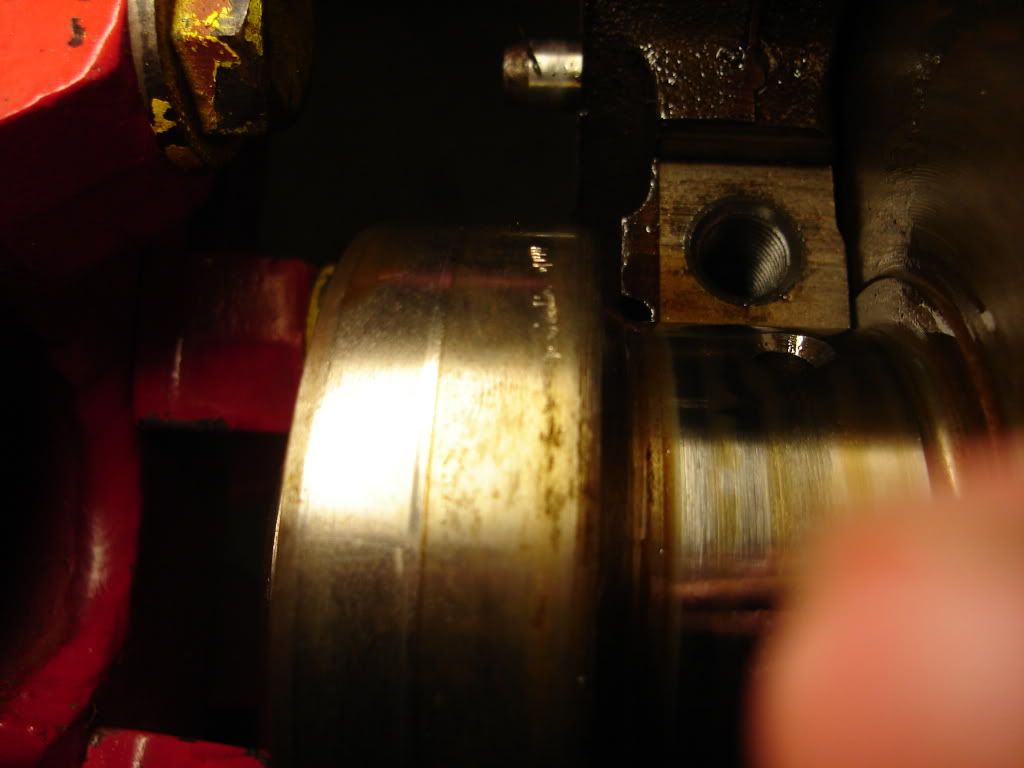

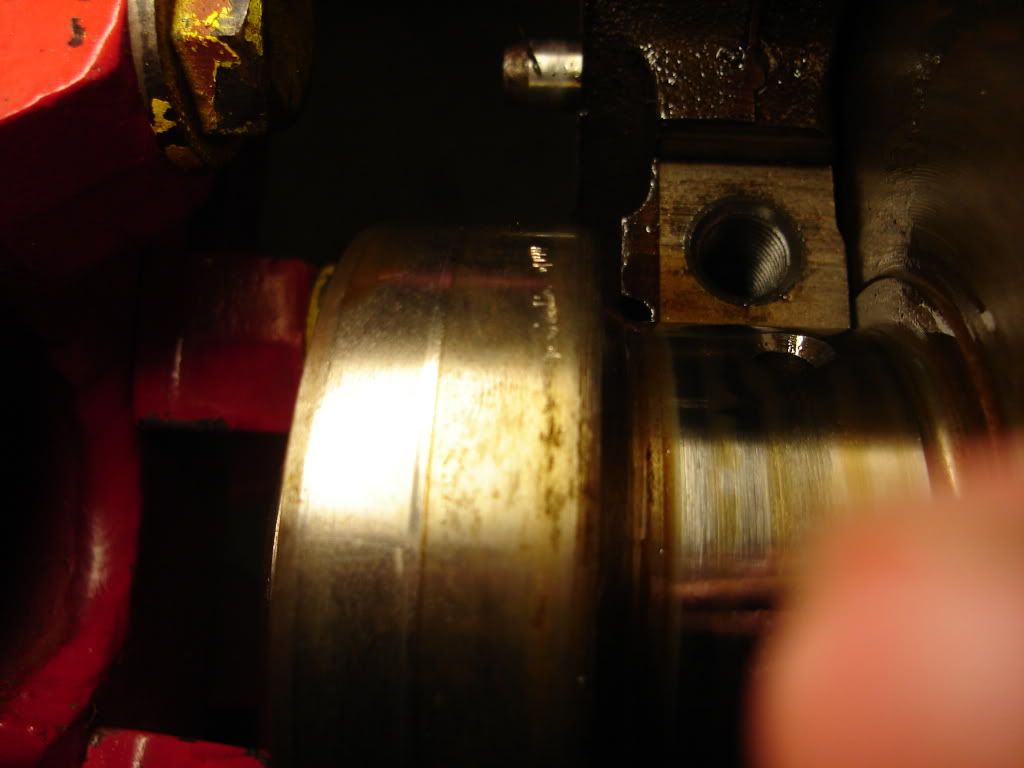

This is the bad scratch - I think it's on the other side of the seal but feel free to give your 2 cents:

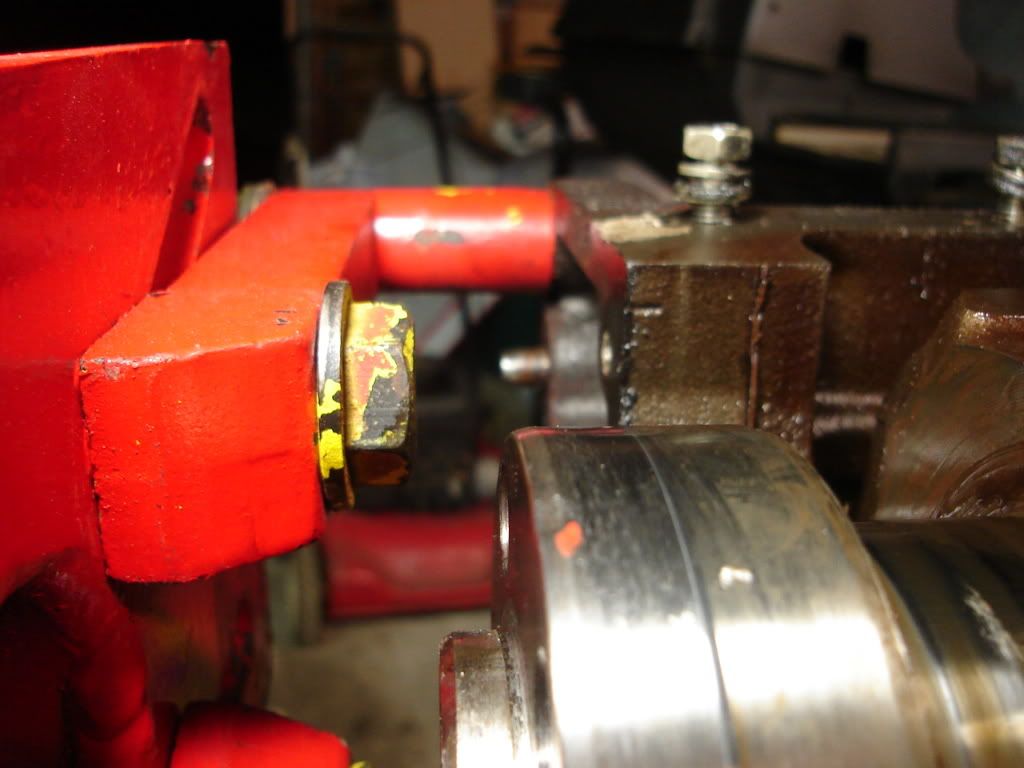

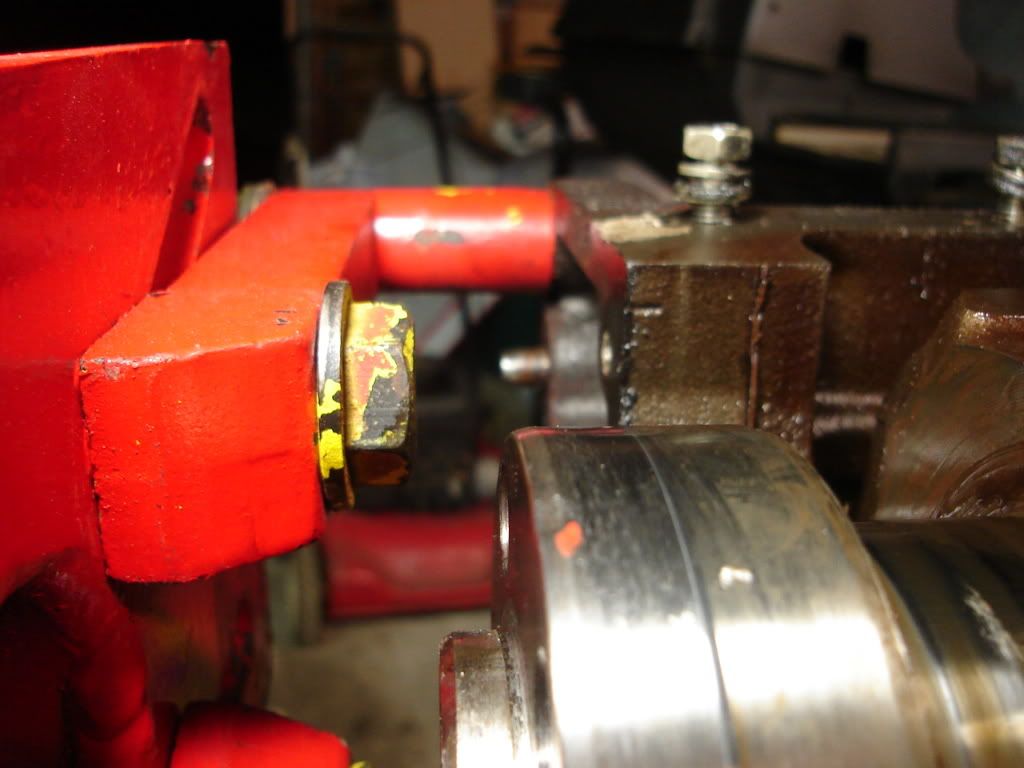

The next here is the dent that occurred on the seal surface. It takes up about half of the seal surface, so I don't know if it's a deal breaker or not. It is right on the red mark (the color of my engine stand, dur)

Aside from surface defects, would this instantly bend the crank? What are my options? I can give it to a machine shop to check it, but if I need another I assume it's better to buy a used crank? But the that has to be checked and maybe ground/machined.

I'd really appreciate some feedback from someone with experience and not just "I heard".

I took my motor apart last week and have had my crank sitting in my block since, no main caps.

A friend came over tonight and I rotated my stand (!!!) forgetting the crank was just resting, and it fell. It fell about two feet to my garage floor. None of the journal surfaces touched, aside from the rear main seal surface.

This is the bad scratch - I think it's on the other side of the seal but feel free to give your 2 cents:

The next here is the dent that occurred on the seal surface. It takes up about half of the seal surface, so I don't know if it's a deal breaker or not. It is right on the red mark (the color of my engine stand, dur)

Aside from surface defects, would this instantly bend the crank? What are my options? I can give it to a machine shop to check it, but if I need another I assume it's better to buy a used crank? But the that has to be checked and maybe ground/machined.

I'd really appreciate some feedback from someone with experience and not just "I heard".