For the purpose of this guide I'm installing boost and voltage gauges. I will also be adding oil pressure + temperature, water temperature, EGT and possibly a wideband in the future so I had to do the groundwork to run all of these gauges. Here are the 5 gauges I have waiting to install:

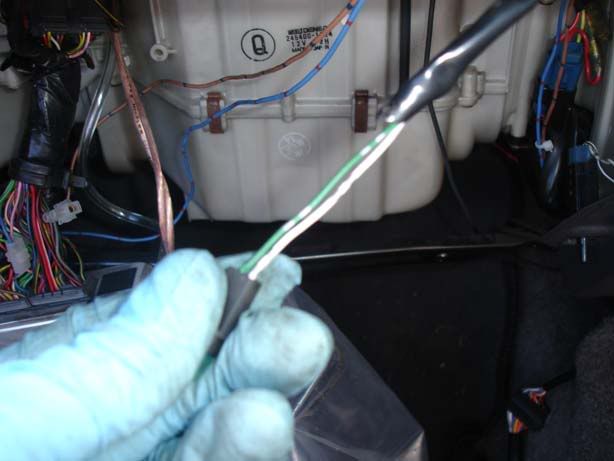

Step 1 - Boost gauge installation. Locate the vacuum hose at the rear of the intake plenum chamber.

Step 2 - Remove the hose by sliding it straight back towards the rear of the car

Step 3 - Get yourself a boost gauge, mine was a 30 psi mechanical gauge (mechanical has a feed of air rather than an electronic signal from a sensor), and cost about £15 so nothing too expensive.

Step 4 - Ensure you have the following (mine came with the gauge)

1. T piece to insert another vacuum line into the stock hoses

2. A length of vacuum line to run to the gauge

3. Power supply to the gauge (You may find it's just a positive and negative on some)

Step 1 - Boost gauge installation. Locate the vacuum hose at the rear of the intake plenum chamber.

Step 2 - Remove the hose by sliding it straight back towards the rear of the car

Step 3 - Get yourself a boost gauge, mine was a 30 psi mechanical gauge (mechanical has a feed of air rather than an electronic signal from a sensor), and cost about £15 so nothing too expensive.

Step 4 - Ensure you have the following (mine came with the gauge)

1. T piece to insert another vacuum line into the stock hoses

2. A length of vacuum line to run to the gauge

3. Power supply to the gauge (You may find it's just a positive and negative on some)