karlou426hemi;2048790 said:I'll now talk about engine rebuild and what to ask from your machinist...

Mandatory steps:

Face head

Face block (don't forget the timing cover when facing the block)

Block decking.

here there is a rule to respect. you want to end up with a piston to head clearance between .035 - .040. For exemple, my head gasket thickness was measured like that:

3 layers : .007,.031,.007 (.045 total)

so to have a piston to head clearance of .040 pistons had to stand out of the block .005 at TDC.

so remove enough material to respect this pistons to head clearance.

Few points here:

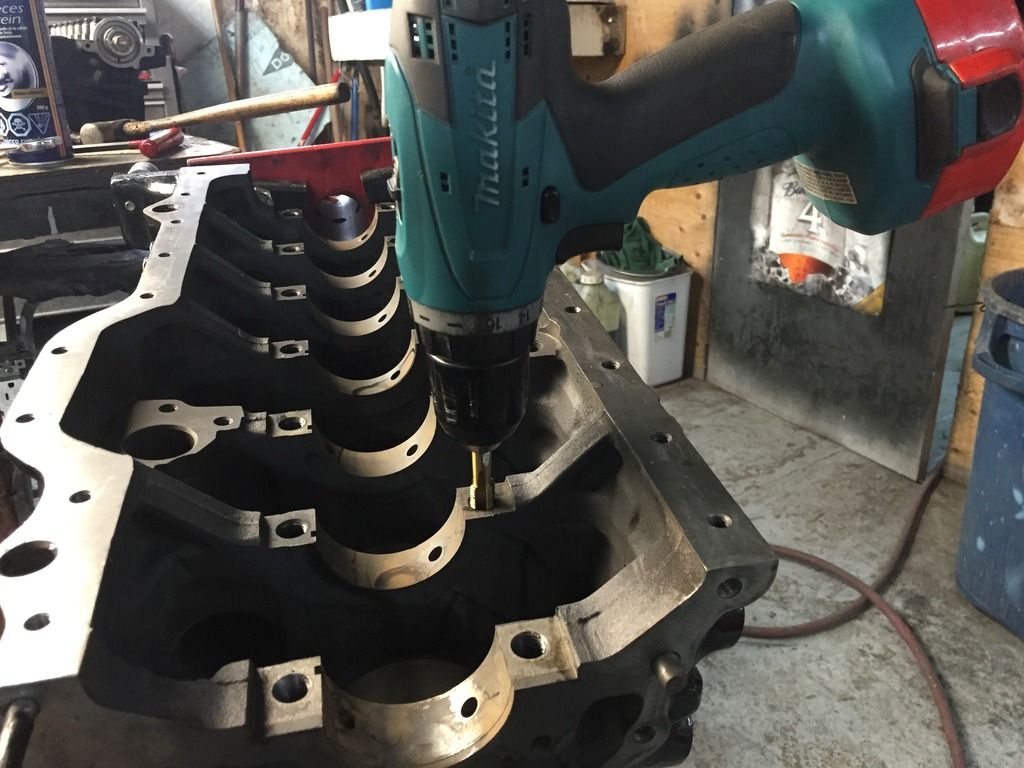

1. Regarding the machining, you left out the part of having the timing belt tensioner installed and torqued to factory specs when doing the machine work because otherwise bore #1 will be distorted out of round when you assemble the motor

2. Regarding the piston to head clearance, having the pistons protruding further from the block is NOT a good idea, if anything you should be having the pistons custom made with offset pins to work with the new deck height if your block requires significant machine work

3. No mention of a torque plate