Recently I've rebuilt my 1989 supra turbo's engine (7MGTE) and I upgraded to a AEM EMS 30-1130. I got the calibration file and did some small tuning and got running very good and smooth, and it drove great and it has tons of power. Just today, I went to start it up to drive it in the garage, and it wouldnt start, so plugged in my laptop to the EMS and added some fuel to the warm up enrichment because its about 30 degrees out. I got it started, but if I gave it some gas, it would immediately stall, which baffled me. I played with fuel map a bit and got it to stop stalling under some throttle, but when I gave it a quick blip of throttle, my wideband shows to leans way out and stalls.. but when I give it a steady increase in throttle, its fine. Its really strange that it runs perfect one day and the next day it cant even take off from a stop without stalling.I'm not sure if blew a intake gasket out when I was automapping it the other day, I don't I did considering it ran very good. My engine has lexus MAF and 550cc injectors and a factory ct-26 turbo 5 speed manual. If anyone here is really familar with tuning, preferbly with the 7MGTE, please help, I would great appreciate it  . I will attached my tune map with this message. Thanks

. I will attached my tune map with this message. Thanks

AEM EMS mk3 supra cold start and engine load problems

- Thread starter fast427

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi I have took a look at your map.

I need to know if you have a wideband in your car, is wired in the ecu, what is the max boost you are running and witch 550cc are you running.

Personnaly i strongly suggest you to rewire your injectors for sequential injection and use a map sensor for load sensor. those two mods with a wideband will permit you to run a lean and steady idle, reduce your fuel consumption (Min 10-15%), give better throttle response and give you the ability to run you car back home if an intercooler hose pop off.

This is just a personnal tip as it is what I did on mine so if you need help to calibrate all this stuff I will be able to help you.

When i was using the stock semi sequential injection i couldn't idle without missfire leaner than 10.8 afr and now my idle is perfect with 15.5 afr. (idling to rich is not good for piston rings)

As for cold start issue I will give you my settings, I live in quebec so here temps drop down to -15f sometimes and my car start on the first try.(when as cold as this I need to give it a bit of gas to help set its idle but i use 10w40 oil so hard to turn engine)

Also for very cold start (below 0f) the calibration provided by aem shut the fuel pump off if below 0f(stupid). I fouled 18 spark plugs before realising that it was not my cold start tunning that was the problem but it was because once started I will no get any fuel and the engine would die

Give me a couple days and i will post back your calibration revised and will explain the changes i did.

Karl.

I need to know if you have a wideband in your car, is wired in the ecu, what is the max boost you are running and witch 550cc are you running.

Personnaly i strongly suggest you to rewire your injectors for sequential injection and use a map sensor for load sensor. those two mods with a wideband will permit you to run a lean and steady idle, reduce your fuel consumption (Min 10-15%), give better throttle response and give you the ability to run you car back home if an intercooler hose pop off.

This is just a personnal tip as it is what I did on mine so if you need help to calibrate all this stuff I will be able to help you.

When i was using the stock semi sequential injection i couldn't idle without missfire leaner than 10.8 afr and now my idle is perfect with 15.5 afr. (idling to rich is not good for piston rings)

As for cold start issue I will give you my settings, I live in quebec so here temps drop down to -15f sometimes and my car start on the first try.(when as cold as this I need to give it a bit of gas to help set its idle but i use 10w40 oil so hard to turn engine)

Also for very cold start (below 0f) the calibration provided by aem shut the fuel pump off if below 0f(stupid). I fouled 18 spark plugs before realising that it was not my cold start tunning that was the problem but it was because once started I will no get any fuel and the engine would die

Give me a couple days and i will post back your calibration revised and will explain the changes i did.

Karl.

View attachment fast427_workmap.V1.19.calView attachment Karlou426hemi_MK3.V1.19.calEngine start:

crank min rpm 50 > 35 help quick start

Fuel pump prime 0 > 3s help with consistant initial crank pulse (always wait 2s before passing from key on to key start)

reworked crank injector time so if to long to start just gently press more and more the gas pedal to inject more. If flooded fully press gaz and start

reworked warm up enrichment table (was a bit to rich)

reworked initial crank pulse (it help quick start)

reworked rpm offset vs start (help keeping it running after start when cold)

reworked start extra decay (this engine need a lot of fuel after a cold start too keep running)

reworked start extra vs temp ( THIS IS TO KEY TO A GOOD QUICK COLD START)

Accel fuel:

reworked accel warm up enrichment table (this table help not to die with quick throttle when cold it will not be perfect because our engine would need more than 100% more fuel when really cold but it help a lot)

Idle:

Idle reset at key off unchecked > checked Those stepper motors need to be reset to know exactly where they are.

idle vs tps table reworked (always leave this at 0 if you want a consistent idle)

idle park target 62% > 50% changing this value change the way you car initialy start (if it does not work well for you try different values)

rev limiter:

Ign cut 7200 > 10000 (use this only when you want a bang in the exhaust and don't care about your engine and exhaust gasket (a properly set fuel cut is a lot easier on an engine)

fuel cut 7400 > 6800 (useless to rev higher than that on the ct26, even my ported head with 1.22a/r s256 will see power drop after 6000 (my fuel cut is 7200 in hight boost (24psi) and 6000 at 5psi))

fuel cut wizard ; ive putted it to hard cut so will not pass 6800 (soft cut will make you go to 7100 by cutting only some injection event but will make a lean exhaust condition) so hard cut= no fuel at all past 6800 so no lean condition)

Fuel table:

Never use the automapping function as it is shit. Always do multiple pulls with different load and ajust your fuel according to your afr in aem log. this method will give you a much smoother looking fuel map. this is what I did and my fuel map look really smooth and i never see more than 5%-7% correction on my o2 feedback.

ignition table:

Try smoothing this out a bit it will help getting a smoother power delivery especially in low rpm condition.

o2 sensor feedback:

Never use this when at full load. I pesonnaly use it up to 9psi but I have a fully forged engine so if my sensor goes wrong and my afr becomes lean i will not burn a hole in my pistons.

Personnaly on stock pistons I would take is off over 5 psi and up there rely only on the fuel map because there is a lot less chance that you fuel map go wrong during a hi boost pull

Knock sensor:

USE THISS!!!!!!! Pretty easy just log a hi boost pull and check you knock readings (assuming there is no knock) then ajust your knock cal table a little bit above your readings at each rpm.

One off the most important parameter on a street car because you never know the quality off the gas you put in so it is your only defense between a bad thank of gas and a blown engine.

I've joined a copy of my personnal map so you will be able to see the difference by youself.

It is the first car I have ever tuned and this map is worth one year and a half of tunning.

With this map my car act as a completely stock car with a better than stock drivability.

The car also regurlarly do 25mpg in average (thanks to sequential injection here).

Here are my mods:

fully rebuilt 7mgte

eagle rods

cp pistons

hks headgasket with studs

ported head

borg warner s200sx 56 1.22a/r (awesome turbo 5psi by 2300, 20psi by 3100 and pull up to 7000)

synapse wastegate

quick spool valbe (hand built)

3in exhaust

cxracing intercooler

rc 550

walbro fuel pump

aeromotive fpr

aem water meth

aem ems

aem 3.5 bar map

aem ait

custom wired internal altitude sensor in ems to compensate boost with outside temp instead of altitude

( help a lot here with temps varying a lot from summer to winter )

other goodies

This set up was not dynoed yet but it putted down 472whp and 467wtq at 20psi with a cxracing t61 upgrade (hated this turbo)

I can tell you that it pulls a lot harder with the s200 and full boost at 3500 in third is a lot more fun on the street than full boost at 5200 with my old t61!!!!

If you have any other problems or need some advice feel free to ask.

Karl.

crank min rpm 50 > 35 help quick start

Fuel pump prime 0 > 3s help with consistant initial crank pulse (always wait 2s before passing from key on to key start)

reworked crank injector time so if to long to start just gently press more and more the gas pedal to inject more. If flooded fully press gaz and start

reworked warm up enrichment table (was a bit to rich)

reworked initial crank pulse (it help quick start)

reworked rpm offset vs start (help keeping it running after start when cold)

reworked start extra decay (this engine need a lot of fuel after a cold start too keep running)

reworked start extra vs temp ( THIS IS TO KEY TO A GOOD QUICK COLD START)

Accel fuel:

reworked accel warm up enrichment table (this table help not to die with quick throttle when cold it will not be perfect because our engine would need more than 100% more fuel when really cold but it help a lot)

Idle:

Idle reset at key off unchecked > checked Those stepper motors need to be reset to know exactly where they are.

idle vs tps table reworked (always leave this at 0 if you want a consistent idle)

idle park target 62% > 50% changing this value change the way you car initialy start (if it does not work well for you try different values)

rev limiter:

Ign cut 7200 > 10000 (use this only when you want a bang in the exhaust and don't care about your engine and exhaust gasket (a properly set fuel cut is a lot easier on an engine)

fuel cut 7400 > 6800 (useless to rev higher than that on the ct26, even my ported head with 1.22a/r s256 will see power drop after 6000 (my fuel cut is 7200 in hight boost (24psi) and 6000 at 5psi))

fuel cut wizard ; ive putted it to hard cut so will not pass 6800 (soft cut will make you go to 7100 by cutting only some injection event but will make a lean exhaust condition) so hard cut= no fuel at all past 6800 so no lean condition)

Fuel table:

Never use the automapping function as it is shit. Always do multiple pulls with different load and ajust your fuel according to your afr in aem log. this method will give you a much smoother looking fuel map. this is what I did and my fuel map look really smooth and i never see more than 5%-7% correction on my o2 feedback.

ignition table:

Try smoothing this out a bit it will help getting a smoother power delivery especially in low rpm condition.

o2 sensor feedback:

Never use this when at full load. I pesonnaly use it up to 9psi but I have a fully forged engine so if my sensor goes wrong and my afr becomes lean i will not burn a hole in my pistons.

Personnaly on stock pistons I would take is off over 5 psi and up there rely only on the fuel map because there is a lot less chance that you fuel map go wrong during a hi boost pull

Knock sensor:

USE THISS!!!!!!! Pretty easy just log a hi boost pull and check you knock readings (assuming there is no knock) then ajust your knock cal table a little bit above your readings at each rpm.

One off the most important parameter on a street car because you never know the quality off the gas you put in so it is your only defense between a bad thank of gas and a blown engine.

I've joined a copy of my personnal map so you will be able to see the difference by youself.

It is the first car I have ever tuned and this map is worth one year and a half of tunning.

With this map my car act as a completely stock car with a better than stock drivability.

The car also regurlarly do 25mpg in average (thanks to sequential injection here).

Here are my mods:

fully rebuilt 7mgte

eagle rods

cp pistons

hks headgasket with studs

ported head

borg warner s200sx 56 1.22a/r (awesome turbo 5psi by 2300, 20psi by 3100 and pull up to 7000)

synapse wastegate

quick spool valbe (hand built)

3in exhaust

cxracing intercooler

rc 550

walbro fuel pump

aeromotive fpr

aem water meth

aem ems

aem 3.5 bar map

aem ait

custom wired internal altitude sensor in ems to compensate boost with outside temp instead of altitude

( help a lot here with temps varying a lot from summer to winter )

other goodies

This set up was not dynoed yet but it putted down 472whp and 467wtq at 20psi with a cxracing t61 upgrade (hated this turbo)

I can tell you that it pulls a lot harder with the s200 and full boost at 3500 in third is a lot more fun on the street than full boost at 5200 with my old t61!!!!

If you have any other problems or need some advice feel free to ask.

Karl.

Hey man, you should change your setup a bit. This is what I have done with the 7M and the AEM and it worked great.

MAP Sensor

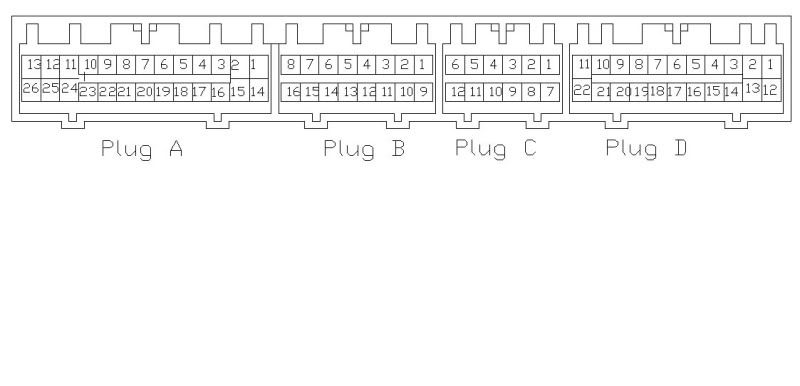

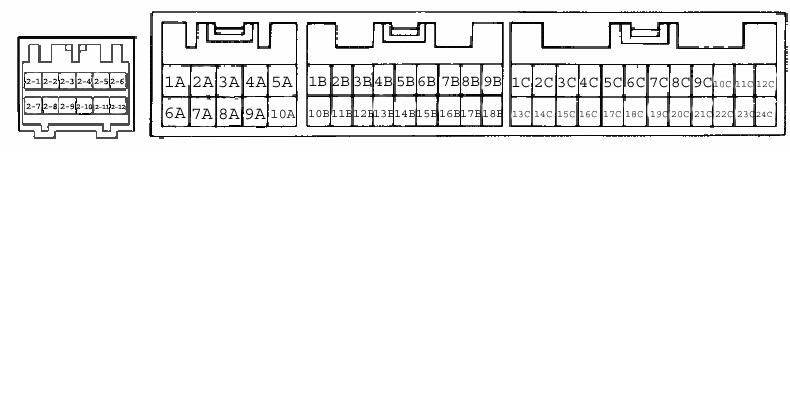

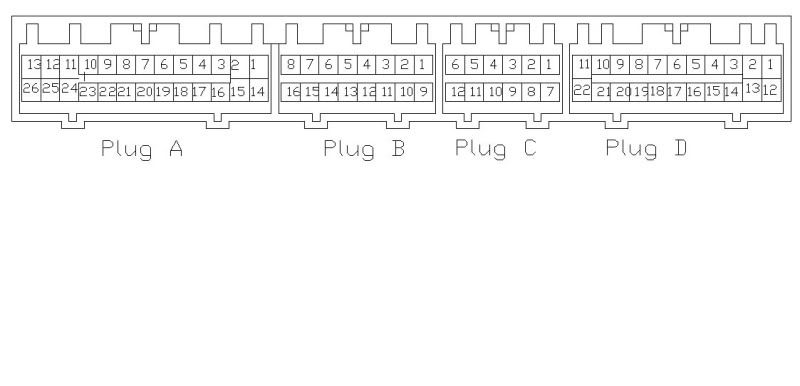

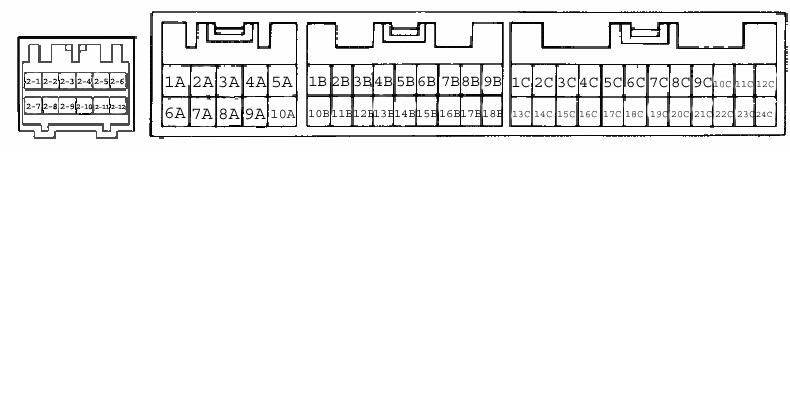

There are 3 wires on a MAP sensor. It requires MAP signal, 5V reference, and sensor ground. If you're using an AEM MAP sensor: MAP signal is green or white, 5V reference is red, and sensor ground is black. The signal wire needs to be dedicated, meaning that should be the only wire making contact with that pin. The sensor ground and 5V reference wire can be tapped. Please follow the pin out below to wire in your MAP sensor. If you did everything correctly, with an AEM 3.5 bar MAP sensor, your MAP voltage (setup/sensors/map sensor parameters) should be about 1.6V with the key on engine off, with an AEM 5 bar MAP sensor, your MAP voltage should be about 1.3V with the key on engine off. Remember to select the correct sensor in your MAP sensor wizard.

MAP signal - Pin 17A

Sensor ground - Pin: 9B and 4C (tap to one of these)

5V Reference - Pin: 1B (tap to this pin)

Air Intake Temp. Sensor

There are 2 wires on a AIT sensor. Polarity does not matter. It requires AIT signal and sensor ground. Please follow the pin out below to wire in your AIT sensor. Remember to select the correct sensor in you AIT sensor wizard.

AIT signal - Pin 3B

Sensor ground - Pin: 9B and 4C (tap to one of these)

Boost Solenoid

There are 2 wires on a boost solenoid. Polarity does not matter. It requires switched 12V and PW2 on EMS. Please follow the pin out below to wire in your boost solenoid.

PW2 - Pin 1C

Wideband (this is for EMS without built in wideband)

If you're using 30-4100 (Gauge type wideband controller), 30-2300/2301 (Dual/Single channel wideband controller), or other wideband controller with a 0-5V output, you will need to tap the 0-5V output wire to the O2#1 or O2#2pin on your EMS. White wire on 30-4100, and orange wire on the 30-2300/2301. Please follow the pin out below to wire in your wideband.

O2#1 - Pin 6B

O2#2 - Pin 14B

To setup the sequential injection follow this.

Injector 4 pin 10C

Injector 5 pin 11C

Injector 6 pin 12C

Then to set it up in AEM pro.

Click "options" then "injectors"

Injectors 1,2,3,7,8,9,10 should be set to "active" and "O2 feedback 1" and "primary"

4,5,6 should not have anything selected.

Then go to "fuel" and then "advanced fuel" then "injector phasing" and finally "options"

Set the injector phase to 0

Inject Tooth #01=19.00

Inject Tooth #02=11.00

Inject Tooth #03=3.00

Inject Tooth #04=0

Inject Tooth #05=0

Inject Tooth #06=0

Inject Tooth #07=15.00

Inject Tooth #08=23.00

Inject Tooth #09=7.00

Inject Tooth #10=0

After that you should be good to go on sequential fuel.

Ignitor options.

Toyota DH61

OEM PIN NAME ~~ DH61 PIN name

B+ ~~ +B

*body ground* ~~ GND *Need to add pin here to ground the ignitor

IGT ~~ T1

IGDA ~~ T2

IGDB ~~ T3

IGF ~~ not used for AEM, **good wire for ECU re-pin for MAP sensor

IG1 ~~ C1 We drove coil 1-6

IG2 ~~ C2 We drove coil 2-5

IG3 ~~ C3 We drove coil 3-4

IG- ~~ Tach

Part numbers:

89621-30030 - DH61 Igniter **These change from year to year, and IS's and GS's are different

90980-11653 - Housing, Connector

82998-12440 - Terminal, Connector

Mitsubishi 3kgt ignitor, I recommend not using this one as it requires the use of a tach driver for the gauge.

VB - 12 volt positive

GND - Ground

IB1 - coil output #1 from AEM (factory iGt wire)

IB2 - coil output #2 from AEM (factory iGda wire)

IB3 - coil output #3 from AEM (factory iGdb wire)

OC1 - output to coils 1 - 6

OC2 - output to coils 2 - 5

OC3 - output to coils 3 - 4

To set up the new ignition system in AEM Pro follow these steps.

*Ignition*

*Advanced Ignition*

*Ignition Phasing*

*Options-Ign phasing*

Then there will be a table, set the perimeters to the following.

Ignition sync: 0.16

Pickup Delay Comp: 130.00

IGN Tooth #1: 21.53

IGN Tooth #2: 1.53

IGN Tooth #3: 5.53

IGN Tooth #4: 0.00

IGN Tooth #5: 0.00

IGN Tooth #6: 9.53

IGN Tooth #7: 13.53

IGN Tooth #8: 17.53

IGN Tooth #9: 0.00

IGN Tooth #10: 0.00

Then to turn off the multi-plexing

*Ignition*

*Advanced Ignition*

*Multi-Plex Coil*

*Options*

The uncheck the box that says "Ign Mux Ign#1"

To run the IS300 coils you will need to run the setup wizard for the coils to do this in AEM Pro follow these steps.

*Ignition*

*Advanced Ignition*

*Coil Dwell Setup*

*Coil Dwell Wizard*

Select "Toyota Coil (93-98 3.0L Non Turbo)

With that you should be set to start the tuning process.

Thanks to Steve (toyotanos) For the information on the DH61 wiring, and to Sean (Xman) For helping me when I was first setting up my AEM EMS.

MAP Sensor

There are 3 wires on a MAP sensor. It requires MAP signal, 5V reference, and sensor ground. If you're using an AEM MAP sensor: MAP signal is green or white, 5V reference is red, and sensor ground is black. The signal wire needs to be dedicated, meaning that should be the only wire making contact with that pin. The sensor ground and 5V reference wire can be tapped. Please follow the pin out below to wire in your MAP sensor. If you did everything correctly, with an AEM 3.5 bar MAP sensor, your MAP voltage (setup/sensors/map sensor parameters) should be about 1.6V with the key on engine off, with an AEM 5 bar MAP sensor, your MAP voltage should be about 1.3V with the key on engine off. Remember to select the correct sensor in your MAP sensor wizard.

MAP signal - Pin 17A

Sensor ground - Pin: 9B and 4C (tap to one of these)

5V Reference - Pin: 1B (tap to this pin)

Air Intake Temp. Sensor

There are 2 wires on a AIT sensor. Polarity does not matter. It requires AIT signal and sensor ground. Please follow the pin out below to wire in your AIT sensor. Remember to select the correct sensor in you AIT sensor wizard.

AIT signal - Pin 3B

Sensor ground - Pin: 9B and 4C (tap to one of these)

Boost Solenoid

There are 2 wires on a boost solenoid. Polarity does not matter. It requires switched 12V and PW2 on EMS. Please follow the pin out below to wire in your boost solenoid.

PW2 - Pin 1C

Wideband (this is for EMS without built in wideband)

If you're using 30-4100 (Gauge type wideband controller), 30-2300/2301 (Dual/Single channel wideband controller), or other wideband controller with a 0-5V output, you will need to tap the 0-5V output wire to the O2#1 or O2#2pin on your EMS. White wire on 30-4100, and orange wire on the 30-2300/2301. Please follow the pin out below to wire in your wideband.

O2#1 - Pin 6B

O2#2 - Pin 14B

To setup the sequential injection follow this.

Injector 4 pin 10C

Injector 5 pin 11C

Injector 6 pin 12C

Then to set it up in AEM pro.

Click "options" then "injectors"

Injectors 1,2,3,7,8,9,10 should be set to "active" and "O2 feedback 1" and "primary"

4,5,6 should not have anything selected.

Then go to "fuel" and then "advanced fuel" then "injector phasing" and finally "options"

Set the injector phase to 0

Inject Tooth #01=19.00

Inject Tooth #02=11.00

Inject Tooth #03=3.00

Inject Tooth #04=0

Inject Tooth #05=0

Inject Tooth #06=0

Inject Tooth #07=15.00

Inject Tooth #08=23.00

Inject Tooth #09=7.00

Inject Tooth #10=0

After that you should be good to go on sequential fuel.

Ignitor options.

Toyota DH61

OEM PIN NAME ~~ DH61 PIN name

B+ ~~ +B

*body ground* ~~ GND *Need to add pin here to ground the ignitor

IGT ~~ T1

IGDA ~~ T2

IGDB ~~ T3

IGF ~~ not used for AEM, **good wire for ECU re-pin for MAP sensor

IG1 ~~ C1 We drove coil 1-6

IG2 ~~ C2 We drove coil 2-5

IG3 ~~ C3 We drove coil 3-4

IG- ~~ Tach

Part numbers:

89621-30030 - DH61 Igniter **These change from year to year, and IS's and GS's are different

90980-11653 - Housing, Connector

82998-12440 - Terminal, Connector

Mitsubishi 3kgt ignitor, I recommend not using this one as it requires the use of a tach driver for the gauge.

VB - 12 volt positive

GND - Ground

IB1 - coil output #1 from AEM (factory iGt wire)

IB2 - coil output #2 from AEM (factory iGda wire)

IB3 - coil output #3 from AEM (factory iGdb wire)

OC1 - output to coils 1 - 6

OC2 - output to coils 2 - 5

OC3 - output to coils 3 - 4

To set up the new ignition system in AEM Pro follow these steps.

*Ignition*

*Advanced Ignition*

*Ignition Phasing*

*Options-Ign phasing*

Then there will be a table, set the perimeters to the following.

Ignition sync: 0.16

Pickup Delay Comp: 130.00

IGN Tooth #1: 21.53

IGN Tooth #2: 1.53

IGN Tooth #3: 5.53

IGN Tooth #4: 0.00

IGN Tooth #5: 0.00

IGN Tooth #6: 9.53

IGN Tooth #7: 13.53

IGN Tooth #8: 17.53

IGN Tooth #9: 0.00

IGN Tooth #10: 0.00

Then to turn off the multi-plexing

*Ignition*

*Advanced Ignition*

*Multi-Plex Coil*

*Options*

The uncheck the box that says "Ign Mux Ign#1"

To run the IS300 coils you will need to run the setup wizard for the coils to do this in AEM Pro follow these steps.

*Ignition*

*Advanced Ignition*

*Coil Dwell Setup*

*Coil Dwell Wizard*

Select "Toyota Coil (93-98 3.0L Non Turbo)

With that you should be set to start the tuning process.

Thanks to Steve (toyotanos) For the information on the DH61 wiring, and to Sean (Xman) For helping me when I was first setting up my AEM EMS.

Personnaly i have not done the igniter swap because i never had a single missfire up to 24 psi of boost with denso IK24 gapped to .034.

The thing that helped the most in my case was setting the gap to .004 in the cam sensor and run in low sensivity from 500 rpm and up with crank and cam sensor.

Running in low sensivity help a lot to not have sync errors (caused by electrical interference) and in fact got me rid of any single missfire i had before. If you don't close the gap, you will lose sync in low sensivity mode somewere between 1000 - 2000 rpm.

Personnaly I only use high sensivity for engine start up.

(If you closely look at my .cal you will notice that my injection phasing is not the same as stated by funky_monkey58 but this is the injection phasing that gave me the richer afr at idle without changing fuel injection value so it mean that it is the good phasing for me)

---- I do not use injector 9, i instead use injector 4 to control my cyl6 injector but it is du to a fault in my ems because injector 9 circuit didn't work so I i opened the box and putted injector 4 circuit on injector9 pin-------

The thing that helped the most in my case was setting the gap to .004 in the cam sensor and run in low sensivity from 500 rpm and up with crank and cam sensor.

Running in low sensivity help a lot to not have sync errors (caused by electrical interference) and in fact got me rid of any single missfire i had before. If you don't close the gap, you will lose sync in low sensivity mode somewere between 1000 - 2000 rpm.

Personnaly I only use high sensivity for engine start up.

(If you closely look at my .cal you will notice that my injection phasing is not the same as stated by funky_monkey58 but this is the injection phasing that gave me the richer afr at idle without changing fuel injection value so it mean that it is the good phasing for me)

---- I do not use injector 9, i instead use injector 4 to control my cyl6 injector but it is du to a fault in my ems because injector 9 circuit didn't work so I i opened the box and putted injector 4 circuit on injector9 pin-------

With the sequential injection I was able to control 1600cc injectors down to a 750rpm idle on E85 here is a cold start video.

http://www.youtube.com/watch?v=FeiODv1ORaY&list=UUMclWd8eOx1bHd9-HKPTitw&index=18&feature=plcp

http://www.youtube.com/watch?v=FeiODv1ORaY&list=UUMclWd8eOx1bHd9-HKPTitw&index=18&feature=plcp

Thanks for responding to my post, and sorry for checking back in a while. Well since I had that problem, I found the EMS wasn't wasn't recognizing the MAF sensor which I later solved. The car ran great until I was doing pulls on the highway and I blew the headgasket  . recently I striped down the engine and replaced the head gasket with a HKS 2.0mm steel gasket and I bought a 3.5 bar AEM MAP sensor and installed a GM AIT sensor. Just today I got the car running and it's running very rich, the wideband is reading 9.8:1 and I thought a plug or wire was bad, so I checked all the plugs, but they all look fine except they are all black (these are new NGK plugs). So I started adjusting the Fuel map around idle, leaning it out to get the AFR's a bit closer to 14.7:1 so it wouldn't foul out a plug, but the engine wasn't responding to the changes I made in the EMS. The AFR's stay the same, very rich. It seems like the Idle is somewhat surging (not badly). I'm thinking the MAP is sensor is some sort of issue here but, I'm not sure if it is or not. I did change the sensor in the MAP sensor wizard and also the AIT sensor as well. I tried to do a data log but, it didnt turn out well because AEM program seems very glitchy. Karlou426Hemi, I tried opening map you sent me, and for some reason it doesn't open it, but I can open your tune that you showed me for an example.

. recently I striped down the engine and replaced the head gasket with a HKS 2.0mm steel gasket and I bought a 3.5 bar AEM MAP sensor and installed a GM AIT sensor. Just today I got the car running and it's running very rich, the wideband is reading 9.8:1 and I thought a plug or wire was bad, so I checked all the plugs, but they all look fine except they are all black (these are new NGK plugs). So I started adjusting the Fuel map around idle, leaning it out to get the AFR's a bit closer to 14.7:1 so it wouldn't foul out a plug, but the engine wasn't responding to the changes I made in the EMS. The AFR's stay the same, very rich. It seems like the Idle is somewhat surging (not badly). I'm thinking the MAP is sensor is some sort of issue here but, I'm not sure if it is or not. I did change the sensor in the MAP sensor wizard and also the AIT sensor as well. I tried to do a data log but, it didnt turn out well because AEM program seems very glitchy. Karlou426Hemi, I tried opening map you sent me, and for some reason it doesn't open it, but I can open your tune that you showed me for an example.

If you are not able to tune it like you want I can do it for you

I recently tuned an AEM equipped mk3 in seatle

What i do is you download a software that let me take control of your laptop. you then go and do some logs on the street.

Finally, based on the logs i can accurately tune your car

I know it seems weird to tune a car without even being there but it worked great with the other guy

Unfortunately, if we start this process it will not be free because it take several hours(yes it is impossible to accurately tune a car in a couple of hours, that's why

professionals take years to tune a car from the factory)

If i tune it i can garantee you that there will be no difference between your car and how a stock car feels(and will have better gas mileage than stock too).

If you are interested about that and want some feedback off my work you just have to write an email to doncrowmk3@yahoo.com, he's the guy that i tuned his car

He contacted me because he found that his car was running like crap after dynotune and it was not starting when cold

I'm sure he will be happy to answer every question you want to ask him. He will also be the better reference you could have to know how accurate my tunes are!

I recently tuned an AEM equipped mk3 in seatle

What i do is you download a software that let me take control of your laptop. you then go and do some logs on the street.

Finally, based on the logs i can accurately tune your car

I know it seems weird to tune a car without even being there but it worked great with the other guy

Unfortunately, if we start this process it will not be free because it take several hours(yes it is impossible to accurately tune a car in a couple of hours, that's why

professionals take years to tune a car from the factory)

If i tune it i can garantee you that there will be no difference between your car and how a stock car feels(and will have better gas mileage than stock too).

If you are interested about that and want some feedback off my work you just have to write an email to doncrowmk3@yahoo.com, he's the guy that i tuned his car

He contacted me because he found that his car was running like crap after dynotune and it was not starting when cold

I'm sure he will be happy to answer every question you want to ask him. He will also be the better reference you could have to know how accurate my tunes are!